Industrial Hydraulics Training Certificate Course

- Home >

- vocational-training >

- mechanical >

- industrial hydraulics training

This training software course, with skills test, makes a great animated study guide for related career skill assessment.

This course covers many hydraulics types and related information in the industry.

Tap the above picture for the industrial hydraulics course demo video.

Full Industrial Hydraulics Training Demo - Content

Industrial Hydraulics Training Course

ESBN: YY1-6798-6040-YA70

Description: (40 hrs)

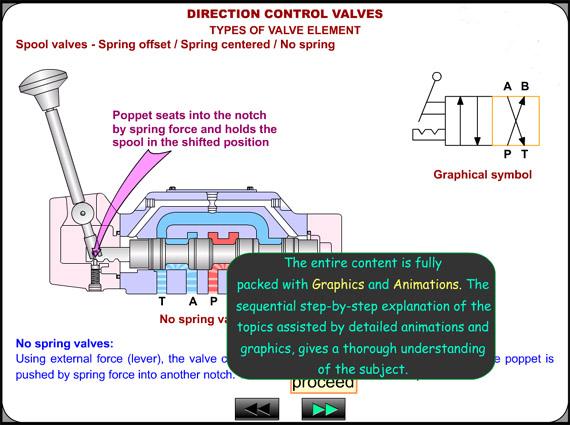

The Industrial Hydraulics Training Course covers hydraulic basics/principles and hydraulic components in explicit detail. The training software course provides detailed knowledge on various components like hydraulic pumps, actuators, directional valves, servo valves, flow control valves, pressure control valves, etc. The industrial hydraulic training program has a dedicated module that builds up a basic hydraulic circuit and gives an in-depth explanation on the relevance and co-ordination of the various hydraulic components.

The primary focus on hydraulic component and hydraulic circuit graphics/animations helps in very clearly understanding hydraulic operating/working principles. Animated cut-sections give a deep insight into how hydraulic components work.

- In-depth coverage on hydraulics-principles

- Detailed description of components and operation

- Build-up of a circuit with two jobs

- Extensive 2D / 3D graphics, models and animations

- Skill tests, certificate printouts

Who Can Benefit:

Students as well as maintenance and engineering personnel who have not had formal training, will find that this computer based training program on industrial hydraulics increases both their knowledge and confidence when performing maintenance. Those with previous training may find this program a good refresher and may learn some important information not covered in their original training.

Hardware Lock:

The Industrial Hydraulics training program is also available in a "Hardware Lock" licensing method. Many users have requested that they be able to use the software on multiple computers, i.e. When working with the program on the office computer and on the home computer. This Hardware Lock method allows users to install software on as many computers as they like. They need only enter the key on which ever computer they are currently wanting to use the software on. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

For the hardware lock option, upon request, we will embed your company logo (replacing the BIN95 logo) in the hydraulics training software, both to give you a customized feel as well as for added protection of your new company software.

(Please note URL of company logo in comment area when ordering or email your logo to us, if you would like to take advantage of this new feature.)

Email confirming order sent within 24 hours after purchase. If you ordered download version, email will contain download link and activation code. If you ordered one of the CD/USB versions, a second email will be sent to confirm shipment.

If you need a SCORM version of the above site license, please contact us and request a quote.

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.)

Hydraulics Course Table of Contents

- 1. Hydraulic Basics

- 1.1. Fundamentals

- 1.1.1. Pressure and Pascal's law

- 1.1.2. Hydraulic leverage / mechanical leverage and simple hydraulic press

- 1.1.3. Hydraulic leverage and energy conservation

- 1.1.4. Simple hydraulic circuit

- 1.1.5. Concept of pressure

- 1.1.6. Relevance of flow in hydraulic circuit

- 1.2. Effect of Flow on System Pressure

- 1.2.1. Pressure buildup when flow is blocked

- 1.2.2. Loss of pressure due to flow (friction)

- 1.2.3. Fluid properties effecting friction

- 1.2.4. Laminar and turbulent flow

- 1.2.5. Flow through restriction

- 1.2.6. Flow through an orifice

- 1.2.7. Flow through resistances in series

- 1.2.8. Flow through resistances in parallel

- 1.2.9. Flow through varying cross-sections

- 1.3. Effect of Load on System Pressure

- 1.4. Factors effecting Pump Suction

- 1.5. Effect of Leak in Hydraulic Circuits

- 1.5.1. Circuit without leak

- 1.5.2. Circuit with leak

- 1.6. Reversing Actuator Direction

- 1.7. Flow Control Circuit

- 1.7.1. Meter-in

- 1.7.2. Meter-out

- 2. Hydraulic Components

- 2.1. Hydraulic Pump

- 2.1.1. Gear pumps

- 2.1.2. Lobe pumps

- 2.1.3. Vane pumps

- 2.1.4. Radial piston pumps

- 2.1.5. Axial - in-line - swash plate piston pumps

- 2.1.6. Axial - bent axis piston pumps

- 2.2. Hydraulic Actuator

- 2.2.1. Linear actuators (Cylinders)

- 2.2.1.1. Single-acting cylinders

- 2.2.1.1.1. Ram

- 2.2.1.1.2. Telescopic

- 2.2.1.2. Double-acting cylinders

- 2.2.1.2.1. Differential

- 2.2.1.2.2. Non-differential (double rod)

- 2.2.1.2.3. Telescopic

- 2.2.1.3. Cylinder - cushioning

- 2.2.1.4. Cylinder - stop tube

- 2.2.2. Rotary actuators (Rotary motor)

- 2.2.2.1. Gear motors

- 2.2.2.2. Vane motors

- 2.2.2.3. Axial - in-line - swash plate piston motors

- 2.2.2.4. Axial - bent axis piston motors

- 2.3. Direction Control Valves

- 2.3.1. Check valves

- 2.3.1.1. Simple (inline) check valve

- 2.3.1.2. Right angle check valve

- 2.3.1.3. Restriction check valves

- 2.3.1.4. Pilot operated check valves

- 2.3.2. Number of ways (ports)

- 2.3.2.1. Two-way valves

- 2.3.2.2. Three-way valves

- 2.3.2.3. Four-way valves

- 2.3.3. Number of positions

- 2.3.3.1. Two-position valve

- 2.3.3.2. Three-position valve

- 2.3.4. Methods of actuation

- 2.3.4.1. Manual actuation

- 2.3.4.2. Mechanical actuation

- 2.3.4.3. Electrical actuation

- 2.3.4.4. Pilot control - Hydraulic / Pneumatic actuation

- 2.3.5. Types of valve element

- 2.3.5.1. Poppet valves

- 2.3.5.2. Rotary valves

- 2.3.5.3. Spool valves

- 2.3.5.3.1. Spool center conditions (three-position valves)

- 2.3.5.3.2. Spring offset / Spring centered / No spring

- 2.3.5.3.3. Pilot operation

- 2.4. Servo Valves

- 2.4.1. Electrohydraulic servo valves

- 2.4.1.1. Single-stage valves

- 2.4.1.2. Two-stage pilot-operated valves

- 2.4.1.3. Jet pipe servo valves

- 2.4.1.4. Flapper jet servo valves

- 2.4.2. Mechanical servo valves

- 2.5. Flow Control Valves

- 2.5.1. By-pass type pressure compensation valve

- 2.5.2. Restrictor type pressure compensation valve

- 2.5.3. Pressure & Temperature compensation valve

- 2.6. Pressure Control Valves

- 2.6.1. Relief valves

- 2.6.1.1. Simple relief valves - poppet type

- 2.6.1.2. Simple relief valves - piston type

- 2.6.1.3. Compound relief valves

- 2.6.2. Sequence valves

- 2.6.3. Counterbalance valves

- 2.6.4. Unloading valves

- 2.6.5. Pressure-reducing valves

- 2.7. Miscellaneous

- 2.7.1. Hydraulic piping

- 2.7.1.1. Pipes

- 2.7.1.1.1. Pipe dimensions

- 2.7.1.1.2. Pipe threads

- 2.7.1.1.3. Pipe fittings

- 2.7.1.2. Tubes

- 2.7.1.2.1. Tube dimensions

- 2.7.1.2.2. Flared compression fittings

- 2.7.1.2.3. Flareless compression fittings

- 2.7.1.2.3.1. Ferrule compression fitting

- 2.7.1.2.3.2. Sleeve compression fitting

- 2.7.1.2.3.3. O-ring compression fitting

- 2.7.1.2.4. Straight thread O-ring connector

- 2.7.1.2.5. Flanged fittings

- 2.7.1.3. Flexible hose

- 2.7.2. Hydraulic sealing

- 2.7.2.1. Flange joint seals / gaskets

- 2.7.2.2. O-ring seals

- 2.7.2.3. Lathe-cut seals

- 2.7.2.4. T-ring seals

- 2.7.2.5. Lip seals

- 2.7.2.6. Cup seals

- 2.7.2.7. Piston rings

- 2.7.2.8. Compression packings

- 2.7.2.9. Face seals

- 2.7.3. Accumulators

- 2.7.3.1. Weight loaded accumulators

- 2.7.3.2. Spring loaded accumulators

- 2.7.3.3. Gas charged accumulators

- 2.7.4. Measuring instruments

- 2.7.4.1. Pressure gauges

- 2.7.4.1.1. Bourdon tube gauge

- 2.7.4.1.2. Schrader gauge

- 2.7.4.2. Flow meters

- 3. Building a Simple Hydraulic Circuit

- 3.1. Job to be done

- 3.2. Simple circuit

- 3.3. Introduce pressure gauge

- 3.4. Introduce relief valve

- 3.5. Introduce direction control valve

- 3.6. Simple circuit with more than one job to be done

- 3.6.1. Pressure gauge / Relief valve / Direction control valve /

Counter balance valve / Non return valve / On-off valve /

Sequence valve / Back pressure valve / Reducing valve /

Flow control valve

- 4. GRAPHICAL SYMBOLS

- 4.1. Lines / Fluid storage / Methods of operation / Fixed displacement pumps /

Variable displacement pumps / Pressure control valves / Flow control

valves / Directional control valves / Proportional valves / Servo valves /

Check valves / Deceleration valves / Hydraulic motors / Cylinders /

Miscellaneous - 5. Conventional and Interactive Skill Tests with Evaluation

Email confirming order sent within 24 hours after purchase. If you ordered download version, email will contain download link and activation code. If you ordered one of the CD/USB versions, a second email will be sent to confirm shipment.

If you need a SCORM version of the above site license, please contact us and request a quote.

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.)

Related Products:

Gas and Air Compressor Training Course

Hydraulics Training Certificate Course

Centrifugal Pumps and Troubleshooting Guide

Industrial Hydraulic Systems and Circuits

Handbook for Machining Equipment Maintenance

Please click here to contact us with your questions and comments.