Learn Positive Displacement Pump Types, Theory, more.

- Home >

- vocational-training >

- mechanical >

- positive displacement pumps

Plus skills test and animated study guide. Also great for skill assessments.

This course covers many pump types and related information in the industry.

Tap the above picture to see the pump course demo.

Full Positive Displacement Pump Training Demo - Content

positive displacement pumps

ESBN: YY1-6798-6040-OQ70

Description: (40 hrs)

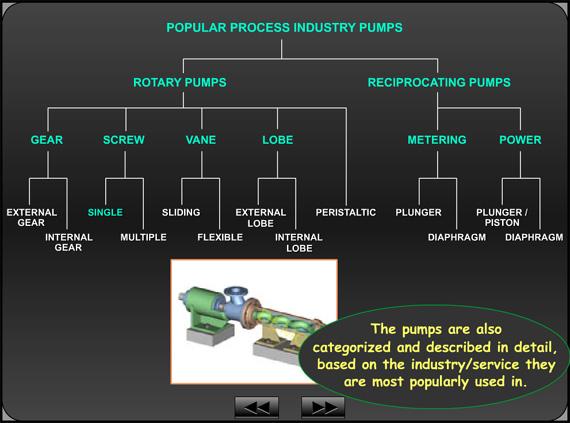

The Positive Displacement Pumps course covers most pump types and their detailed classifications.

The training software utilizes graphics and animations to convey concepts. It makes pump maintenance, operating principles, and repair very clear.

The package includes animated explanations of all types of pumps.

| For example: | |

| Gear Pumps | Axial Piston Pumps |

| Lobe Pumps | Swash Plate Piston Pumps |

| Vane Pumps | Wobble Plate Piston Pumps |

| Screw Pumps | Bent Axis Piston Pumps |

| Peristaltic Pumps | Radial Piston Pumps |

| Metering Pumps | Mud Pumps |

| Power Pumps | Variable Displacement Pumps |

| Diaphragm Pumps | Beam Pumps |

| Sucker Rod Pumps | Hydraulic Pumps |

The pump training program has a module for troubleshooting. Animated cutout sections give insight into pump operation and how pumps work.

- We cover and classify an extensive range of pumps.

- Pumps are also categorized and described based on their industrial services.

- Extensive 2D/3D graphics, models, and animations.

- An interactive, graphically-supported troubleshooting guide.

- Skill tests, certificate printouts.

Who Can Benefit:

Untrained students and maintenance staff will find this training on Positive Displacement Pump helpful. It will boost their knowledge and confidence in maintenance work. Those with prior training may find this program a good refresher. They may also learn important information outside of their original training.

Hardware Lock:

This course is also available using a "Hardware Lock" licensing method. Many users want to use the software on multiple computers. For example, they want to work with it on both their office and home computers. This Hardware Lock method allows users to install the software on as many computers as they like. They only need to enter the key on whichever computer they want to use the software. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

You can also ask us to embed your company logo in the training software for the hardware lock option.(Please note the URL of your company logo in the comments when ordering, or email your logo to us to use this feature.)

We will send an email confirming the order within 24 hours after purchase. If you ordered a downloadable version, check your email. It has the download link and activation code. We send a second email with tracking info if you ordered one of the shippable versions.

Download (1 Installation on 1 PC, Unlimited users, 1 User at a time.) $149

1 Hardware Lock (Unlimited Installations, Unlimited number of PCs, 1 User at a time.) $349

1 Network Hardware Lock (Network Installation, Unlimited number of PCs, 10 Users at a time.) $1049

1 Network Site License (Network Installation, Unlimited Simultaneous PCs and Users) $2100

Pump Course Table of Contents

1. Introduction

- 1.1. Principle of Operation

- 1.2. Classification

- 1.2.1. Rotary Pumps - Various types

- 1.2.2. Reciprocating Pumps - Various types

2. Common Process Industry Pumps

- 2.1. Rotary Pumps

- 2.1.1. Gear Pumps

- 2.1.1.1. External Gear Pumps

- 2.1.1.2. Internal Gear Pumps

- 2.1.2. Lobe Pumps

- 2.1.2.1. External Lobe Pumps

- 2.1.2.2. Internal Lobe Pumps

- 2.1.3. Vane Pumps

- 2.1.3.1. Sliding Vane Pumps

- 2.1.3.2. Flexible Vane Pumps

- 2.1.4. Screw Pumps

- 2.1.4.1. Single Screw Pumps (Progressing Cavity Pumps)

- 2.1.4.2. Multiple Screw Pumps

- 2.1.5. Peristaltic Pumps

- 2.1.1. Gear Pumps

- 2.2. Reciprocating Pumps

- 2.2.1. Metering Pumps

- 2.2.1.1. Plunger Pumps

- 2.2.1.2. Diaphragm Pumps

- 2.2.2. Power Pumps

- 2.2.2.1. Plunger / Piston Pumps

- 2.2.2.2. Diaphragm Pumps

- 2.2.1. Metering Pumps

3. Common Oil Field Pumps

- 3.1. Beam Pumps (Sucker Rod Pumps)

- 3.2. Hydraulic Pumps

4. Common Hydraulic Service Pumps

- 4.1. Gear Pumps

- 4.2. Lobe Pumps

- 4.3. Vane Pumps

- 4.4. Piston Pumps (includes Variable Displacement Pumps)

- 4.4.1. Radial Piston Pumps

- 4.4.2. Swash Plate Pumps (Axial Piston Pumps)

- 4.4.3. Wobble Plate Pumps (Axial Piston Pumps)

- 4.4.4. Bent Axis Pumps (Axial Piston Pumps)

5. Interactive Troubleshooting Guide

Based on the symptoms listed below, the possible problems are identified. Descriptions are graphically empowered for clarity and customized per pump type.

- Rotary Pumps:

- No Liquid Delivery

- Insufficient Discharge Pressure

- Insufficient Capacity

- Starts, but Loses Prime

- Excessive Wear

- Excessive Heat

- Excessive Noise and Vibration

- Excessive Power Demand

- Motor Trips

- Elevated Motor Temperature

- Elevated Liquid Temperature

- Reciprocating Pumps:

- No Liquid Delivery

- Insufficient Capacity

- Short Packing Life

- Excessive Wear at Liquid End

- Excessive Wear at Power End

- Excessive Heat at Power End

- Excessive Noise and Vibration

- Motor Trips

6. Conventional and Interactive Skill Tests with Evaluation

Related Products:

Gas and Air Compressor Training Course

Hydraulics Training Certificate Course

Centrifugal Pumps and Troubleshooting Guide

Industrial Hydraulic Systems and Circuits

Hazardous Area Instrumentation Training

Handbook for Machining Equipment Maintenance

PLC Training Video Series (10 DVD Set w/ workbook)

Please contact BIN95 with your questions and comments.