Maintenance Planner Scheduler Training Course

Download the maintenance management PowerPoints today!

The Maintenance Planning and Scheduling Training course is different than others. These 229 slides in 3 Maintenance Management PowerPoints have a storyline that hopefully will entertain you as these PowerPoints teach you. The author wanted to make maintenance training fun for you to do, and for him to write. So he made the PowerPoint into a story of how Ted (he’s imaginary) learned to become a 'Top-Gun' Maintenance Planner and Scheduler.

Maintenance Planner Training

Maintenance Planner Scheduler Training Course PowerPoint's (24hours)

Prod #: PPT-458M-3C02-12A3

Maintenance Planning and Scheduling training course outline:

DAY 1 (97 Color PowerPoint slides)

The role of Maintenance Planning in business and its foundation basics.

DAY 2 (71 Color PowerPoint slides)

All about planning maintenance systems, methods and practices.

DAY 3 (61 Color PowerPoint slides)

Working with the backlog and scheduling maintenance work.

These 3 Management PowerPoints will enable you to:

- Deepen your understanding of the topic.

- Adapt the presentation to your own needs.

- Show the presentation in your own company.

- Communicate the knowledge of Maintenance Management to your colleagues in your organization.

The content of this Maintenance Planning and Scheduling Training course is exactly what you would see if you attended the actual 3-day Maintenance Planner Training Course. Again, this Maintenance Planning Training Course is different from other company's courses because it is tailored from 30 years of real-life experience as a tradesman, professional engineer, and Maintenance Manager.

Ted’s story follows the content of the Maintenance Planning Training Course. The first day introduces people to the big issues of plant and equipment maintenance and reliability. It covers the foundations of maintenance planning and scheduling so you can see the important role maintenance planning plays in keeping an operation running at full capacity and efficiency. Day Two is all about planning maintenance. You will be introduced to its necessary systems, methods, and practices. Day Three includes working with the backlog and scheduling maintenance work, so the maintenance planner does it in the quickest time and with the least interruption to production.

Have a great time learning to be a ‘top-gun’ Maintenance Planner and Scheduler.

(After purchase with the 'Add to Cart' button above, you immediately receive an email from PayLoadz with the download link.)

For individuals wanting independent study material and instructors wanting to use in class.

About the Instructor ...

Qualifications: Tradesman Fitter Machinist Professional Mechanical Engineer (1st Class Honors) Project Engineer Maintenance Engineer Master Business Administration Maintenance Manager

Engineering Work History: Nova Machinery – Manufacturer Press Brakes & Guillotines Mike Sondalini Bricklaying - Building Construction Swan Brewery – Beverage Riverton Engineering – Sheet Metal Fabrication Coogee Chemicals – Mining & Agricultural Chemicals Manufacture Lifetime Reliability Solutions – Lean, Maintenance & Asset Life-Cycle Risk Management Consulting

Maintenance Planner PowerPoint Samples

A sample of some topic headings found within. (229 PowerPoint Slides) …

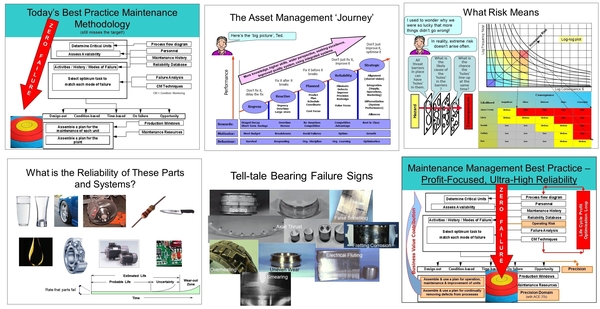

DAY 1 of Maintenance Planner Seminar:

(97 PowerPoint Slides)

[Day 1 - Maintenance Planning Scheduling PowerPoint Sample - Detailed PowerPoint topics]

Introduction

About the Author

The role of Maintenance Planning in business and its foundation basics

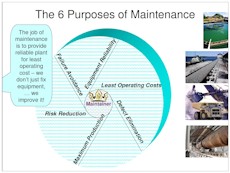

The 6 Purposes of Maintenance

Plant and Equipment Life Cycle

Effects of Maintenance Costs

Equipment Item Failure Total Domain

Risk Management Process

Identify Your Equipment Risks and Priority Equipment

Develop an Equipment Criticality Matrix

Choosing of Maintenance Type

Physics of Failure

Failure Mode Effects Analysis (FMEA) Fundamentals

When and How Much Maintenance?

Maintenance Strategies for Risk Reduction

Measuring Plant & Equipment Performance

Set Standards and Standardize their Use

6 Mechanical Equipment Care Standards to Set, Use and Keep Using

Vibration:

Using Precision Maintenance

Creative Disassembly – Pre-shutdown of Equipment

Creative Disassembly – At Shutdown

Creative Disassembly – At Strip-down

Using Condition Monitoring to Optimize Availability

A Roadmap for Reliability Improvement

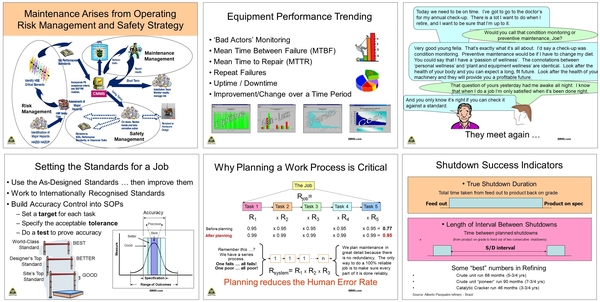

DAY 2 of Maintenance Planner Seminar:

(81 PowerPoint Slides)

[Day 2 - Maintenance Planning Scheduling PowerPoint Sample - Detailed PowerPoint topics.]

The Purpose of Planning Maintenance

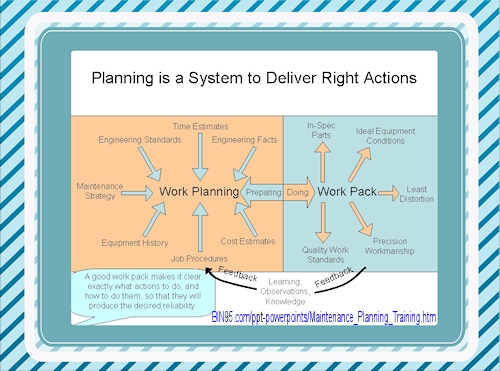

Planning is a System to Deliver Right Actions

Putting Maintenance Strategy into Action

The Value Stream Concept

Necessary Planning Systems

Scoping-out a Job

Work Order Costing

Planning Documents and their Control

Job Procedures

Job Records and their Control

Equipment Performance Trending

Job Performance Trending

Track Planning Performance & Benefits

Job, Work and Personnel Safety

Specifying Workmanship Standards

Standardize the Work

Failure Preventing Job Procedures

Including 3T Failure Prevention in SOPs

Inventory Purchasing and Management

Important Purchasing Information

Useful Parts Control Practices

Working with and Developing Suppliers

Equipment Refurbishment Decisions

And the Cost Drivers

Project Management Principles

And Practices

Bar Charting Plans and Activities

How Much Maintenance Planning is Enough?

Shutdown and Outages Planning

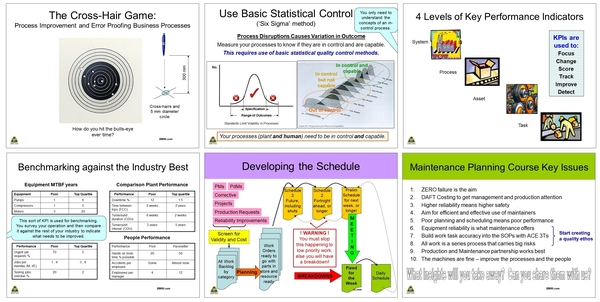

DAY 3 of Maintenance Planner Seminar:

(67 PowerPoint Slides)

[Day 3 - Maintenance Planning Scheduling PowerPoint sample - Detailed PowerPoint topics.]

What causes maintenance …

Common Defect Management Strategies

Defect Elimination & Failure Prevention

(Two sigma to five sigma)

Reliability of Series Work Process

Parallel Process Reliability

Use Basic Statistical Control

(‘Six Sigma’ method)

Control charts give feedback

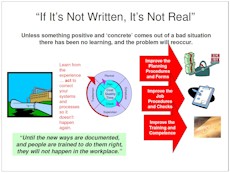

Accuracy Controlled Enterprise (ACE) Standard Operating Procedures

Standardizing Planning Procedures and Scheduling Procedures

4 Levels of Key Performance Indicators

Measuring and Trending Processes

Trend to Monitor KPIs

Showing Progress

Visual Management in All Occasions

Planning and Maintenance Key Performance Indicators (KPI)

DuPont KPI Expectations

Scheduling in a Snap Shot

Scheduling Makes Available Time, Place and Resources to Do the Work

Scheduling also Means Rescheduling

Display the Plan and Responsibilities

Team Building / Relationship / Partnership

Make The Production Plan the Maintenance Plan

Manpower Scheduling and Resources Scheduling

Preparations before Scheduling Starts

Preparations by the Equipment Owner Before the Job Starts

Preparations by Maintenance before the Job Starts

Addressing On-site Issues and Changes in the Plan

Work Through a Job Risk Analysis

Actions Following Job Completion

Monitoring Job Performance and Schedule

Backlog Management

The key aspects of successful backlog management are:

Planning Backlog Management

Ted finishes …

The Purpose of Planning Maintenance

(After purchase with the 'Add to Cart' button above, you immediately receive an email from PayLoadz with the download link.)

For individuals wanting independent study material and instructors wanting to use in class.

Related Titles:

Business Strategy Management with KPI eBook

Employee Training and Development with SOP eBook

Maintenance Management PowerPoint Download