Allen Bradley PLC Programming Certificate Course

- Home >

- vocational-training >

- plc-training >

- allen-bradley >

- allen bradley plc programming

1st PLC Basics, then Allen Bradley PLC Programming Basics training software.

New to PLCs? This PLC Trainer Download is for you.

The PLCTrainer Software is recommended before any other PLC training occurs. This PLC basics course is based on and simulates Allen Bradley PLC programming software. However, 80% of the knowledge can be applied to any brand of PLC. This PLC training download never expires; if you lose your copy, we've got your back (free replacement if lost).

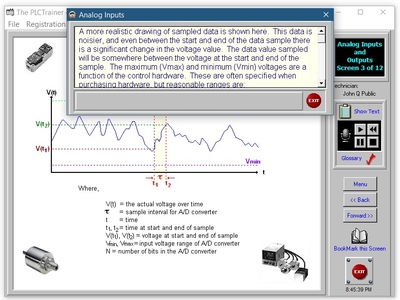

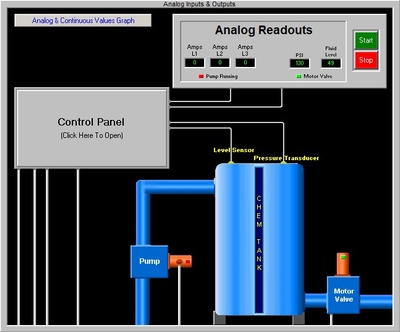

This PLC programming training software includes analog instruction, an area that most training materials have overlooked. The PLC Trainer includes a PLC Laboratory Manual full of proven practical applications. The lab manual allows the student to understand the PLC programming instruction set better. The screens demonstrating the PLC programming instructions have the look and feel of RSLogix (Allen Bradley's PLC programming software). Plus, if you own a copy of RSLogix you can open it from within the PLCTrainer course!

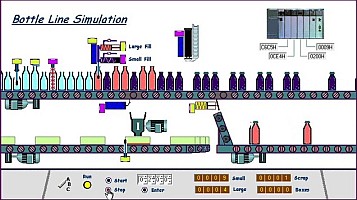

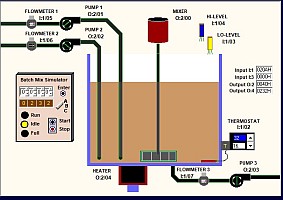

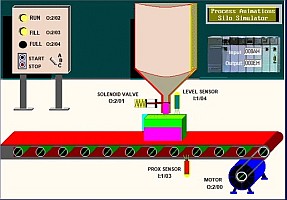

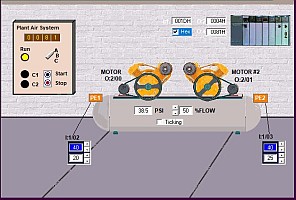

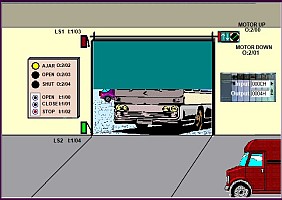

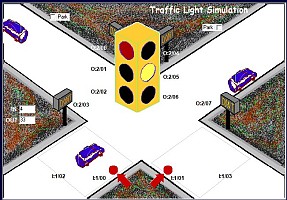

Above is a screen recording of a student using 1 of the 40-plus PLC simulations built into this PLC programming basics course. Most people understand better and retain the knowledge/skill longer by doing hands-on with the built-in PLC simulations. Those new to PLCs may find this learning-by-doing much easier and more effective. A PLC programming basics book, online content, or a video may suit some but lacks the hands-on. This course covers all three learning styles: built-in audio narration, text transcript, videos, and interactive PLC simulations.

Sections:

PLC Basics Intro

Input/Output Modules

Safety Circuit

PLC Processors

Numbering Systems & Codes

Basic PLC Programming

Timer Instructions

Counter Instructions

Program Control Instructions

Data Manipulation

Math Functions

Shift Registers & Sequencers

Analog Inputs & Outputs

Networks

Human Machine Interfaces

Troubleshooting PLCs

Testimonial:

Mike Smith - Instructor - Francis Tuttle Tech Center

"I purchased the PLC Trainer [Multi-user Site License] software after seeing it being used in training classes at Bama Foods in Tulsa. The engineering manager said they searched the Web for PLC training software and found Koldwater Industrial Technology [a subsidiary of BIN95]. My students really like to use the software to help them understand the book we use. After using the PLC trainer, I purchased the LogixPro PLC simulator. It is excellent! It allows you to experiment with the programs at home. My students are really enjoying the ability to try out programs before they input them on the real PLC's. Any time I have emailed questions, I received a reply almost immediately! This is a great company with which to do business. Thanks for supporting the educational community!"

Within 24 hours of placing the order, you will receive an email with a download link and activation information.

Order a Single Student License above or unlimited students/installs per physical site with the Site License.

For unlimited physical site licenses (locations), please Request a Quote for the Enterprise License.

More Allen Bradley PLC Programming Basics samples:

PLC analog inputs and outputs are discussed, as are the mathematical relationships involved in the PLC tutorial.

The video below gives you a sample of the audio narration built into the AB PLC Programming Basics certificate course. This is not a video in the course. Instead, we made the video by recording the screen as the student goes through the course interactions and simulations. Then, we added some extra annotations in red font to make the free PLC training video more valuable and educational for those who view it online. There are a few videos built into the interactive course software. Still, most of what is shown in our demo videos are screen recordings of students using interactive content and simulations. (Note: Koldwater is a subsidiary of BIN.)

Also built into the course software is the LogixTraner designed to familiarize students with using Allen Bradley's PLC programming software RSLogix 500. The LogixTraner has 3 sections/simulators. They are Logix menu navigation, configuring communications, and hardware setup. Below is a screen recording of the navigation tutorial RSLogix 500 simulations being used.

Below is a screen recording of the student using the configuring communication simulation in the LogixTrainer part of the course. Allen Bradley PLC programming software communicates with their software called RSLinx, as shown in the screen recording below. The student/user is the one clicking on and typing in the simulator shown below. It looks and feels like real Allen Bradley RSLogix/RSLinx, but it is just the simulator simulating AB/Rockwell software for the student.

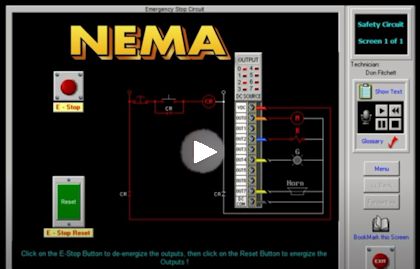

As well as the basics of Allen Bradley PLC programming being covered, so are the basics of PLCs in general. Like the first consideration in automation design, the PLC safety circuit (E-stop), etc. A demo is shown in the video below. (Koldwater company seen in the video is a subsidiary of BIN.)

PLC Programming Instructions:

In older equipment, thumbwheels may be used for data entry. (After all, industrial equipment can last for decades.) The PLC programming Binary Coded Decimal instructions FRD and TOD are handy in dealing with them. They are also handy for learning BCD. Data manipulation instructions like the FIFO load and unload example pictured here (screen recording of a student using) are explained with interactive PLC programming simulations.

Below are a couple more examples of the built-in interactive PLC simulator used to explain and give a better understanding of the PLC instructions being taught.

PLC Troubleshooting:

Example of plc troubleshooting exercises. The more you practice PLC troubleshooting, the more significant your skill increases and the less downtime you have. This PLC training software provides a safe environment in which to practice. The entire PLC tutorial also includes narration! Realistic "work orders" are displayed on the screens that require the technician to troubleshoot a PLC-managed automation system!

LogixPro Allen Bradley PLC Simulator

(Click pictures to zoom in or see screen recordings of students using interactive Allen Bradley PLC simulations in the LogixPro PLC Simulator included free with this course.)

More screenshots from the LogixPro Allen Bradley PLC simulator are in this PLC PDF.

Note: The LogixPro Allen Bradley PLC simulator is included with this PLC course as a free extra.

LogixPro is not required to take or pass the course. It is just an extra we provide for free to give the students more hands-on experience.

Site and Enterprise License purchaser will receive 10 PC licenses for the LogixPro Allen Bradley simulator software with the PLC Course Site or Enterprise license.

Allen Bradley PLC Programming Basics - Features:

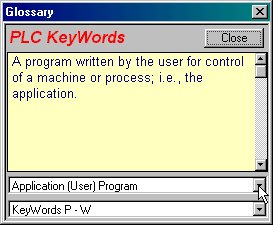

The PLCTrainer also includes an extensive PLC glossary of terms standard to PLC technology.

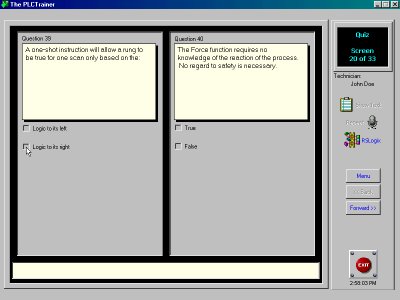

The PLC tutorial comes with an interactive, self-scoring final exam! Along with the interactive "self-scoring" final exam, the student can print a PLC training certificate of completion upon scoring 85% or better.

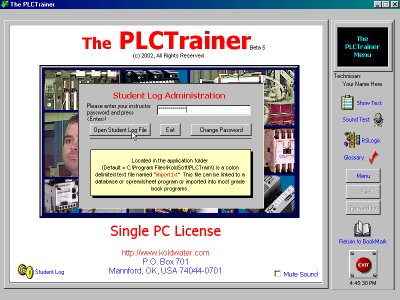

School and Company multiple user licenses:

Even if the PLC training certificate is not printed, the score and student name are saved in the "student log file" accessible by Site and Enterprise license holders. Additionally, when the quiz is scored, the student’s name and final score are appended to a comma-delimited text file that may be imported into a database or spreadsheet application.... making the site license purchasing option perfect for Technical Schools, Community Colleges, Universities, Apprenticeship Programs, and company training departments. A PLC PDF Laboratory Manual full of college-proven and tested programming assignments is included with the tutorial. The PLC PDF Manual is in Adobe PDF format that you can print.

Because this Allen Bradley PLC Programming Basics course starts from a beginner level of what a PLC is and uses interactive simulations to make learning easier, it will also work for High School students. To ensure a good start, HS students should have some working knowledge of motor controls before taking this course.

More PLC simulator examples:

Allen Bradley PLC Hardware Configuration - PLC Analog Interactive Simulation - PLC Boolean Interaction - PLC Fault Simulator - How a PLC Works - PLC Networks Interactive - PLC Troubleshooting

Still not sure if you want to take this certificate course or have your students or employees take it? Try it out first by downloading the Free PLCTrainer in demo mode.

After reviewing all the Allen Bradley PLC Programming Basics certificate course details and samples above, you should be ready to decide.

If not, please contact us with your questions. Thanks

Within 24 hours of placing the order, you will receive an email with a download link and activation information.

Order a Single Student License above or unlimited students/installs per physical site with the Site License.

For unlimited physical site licenses (locations), please Request a Quote for the Enterprise License.

Learning Path:

We recommend:

1st Electrical Motor and Controls Course

2nd PLC Basics (page you are on now)

3rd Electrical and PLC Troubleshooting

4th HMI Basics

5th PAC - Controllogix and RSLogix 5000

6th Online PLC Structured Text Programming Basics Course

7th SCADA Basics

The product on this page is part of the "Automation Technician's bundle" (Bundle to Save an additional 32%)