Lean Training: 5S Lean Manufacturing Training Video

- Home >

- 5slean-videos >

- 5s lean manufacturing training

Teaches what is 5s in manufacturing and the 5s lean manufacturing principles.

This course takes employees through each stage of the 5S principles from Sort through Sustain.

Click the above picture for a Demo of the 5s lean manufacturing training video ( and see Spanish demo)

Example of 5s lean manufacturing training

5s Lean Training Video

(English) ISBN: 609224267819

(Spanish) ISBN: 609224268687

Description:

This 5s lean manufacturing training video is 40 minutes long (Updated to HD MP4 format Sept 2022). This lean manufacturing training video ensures the key concepts of 5s are communicated to employees. The 5s lean training takes the audience through each stage of the 5s process from sort through sustain.

5S Sort - Poka Yoke Examples

5S - Set in Order

5S - Shine

5S - Standardize

5S - Sustain

Who Can Benefit:

Although our targeted audience is clearly Manufacturing training and factory training, 5S Lean training is of great financial benefit to all businesses. As you watch the 5S Lean Training demo video, you will see many real-world examples that demonstrate how all businesses can be more productive by implementing 5S Lean practices. (You'll see examples of how you are probably already using 5S Lean in your personal life too, and just didn't realize it.)

-

All salary and hourly employees

-

All companies

-

All industries

Format/License Details:

The default license is a single "Student" license on USB thumb drive with the MP4 HD video for the individual learner.

The default license is a single "Student" license on USB thumb drive with the MP4 HD video for the individual learner.

Optionally, Schools and Companies can order one or more unlimited student/employee Site Licenses (SL) for each of their campuses/facilities.

The highly flexible Site Licenses allows school or company to use the 5S Lean Training video any way they see fit as long as it is not accessible outside the licensed physical location. With the Site License, the video can be used stand-alone, to supplement existing training material, to create a new course, etc.

Customer Comment:

"This video series is great, the attention to detail is outstanding, and the way each of the 5S steps was explained really made it easy to expand our 5S program. I would recommend this to anyone in a lean or 5S program." -John Frances "Black Belt", FL

Not sure if you or your employees need this training? Have them take our Free online 5S Lean Assessment. You may find they need a refresher.

An email confirming the order will be sent. A second email will be sent to confirm the USB shipment within 24 hours.

5S Lean Training Video (English):

Price: US$159

Sale $99.00

Save Now

5S Lean Training Video (Spanish):

Price: US$189

Sale $99.00

Save Now

5S Lean Training Video (BOTH English and Spanish version bundle):

Price: US$329

Sale $189.00

Save Now

Order a Single Student or Unlimited Site License above.

After purchase, you receive an order confirmation email from PayPal. Within 24 hours you will receive a second email with the USB shipment information.

Examples of This 5S Lean Training

This is an overview of 5s with their associated benefits.

- There are many that believe 5S is just about housekeeping. This is a myth that will soon be busted.

- The 5S's are sort, set in order, shine, standardize, and sustain in that order and starting with sort.

- To sort, you first have to determine what is needed and not needed in the area. consider equipment, tools, materials, supplies, and even paperwork.

- The benefits of sorting are:

- More floor space, which leads to fewer things to trip over.

- Less wasted motion increases productivity.

- Sorting may even improve health conditions.

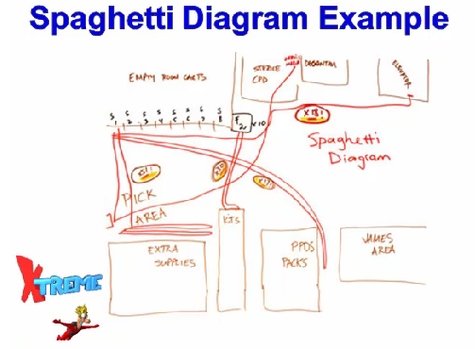

- Set in order includes determining the best locations for machines and equipment. Here is an example of a department before 5s, and after.

- Set in order includes determining the best locations for tools. Making tools easy to find and put away and clearly labeled.

- Tools should be stored at the point of use. If a wrench is needed to adjust this machine, it should be stored as close to the point of use as possible.

- Creating locations for everything in the area and labeling them is another part of setting in order.

- Some of the benefits of setting in order include the elimination of searching waste - looking for needed tools is a waste of motion, and less wasted motion means higher productivity and faster set-up times.

- The "Shine" actually does have to do with housekeeping and that is where the myth comes from. Shine includes cleaning the floors, and the surfaces of everything, cleaning the windows will let natural light in, and cleaning machines will make it easy to inspect the machines for leaks or other maintenance problems that need to be addressed.

- Some of the benefits of shine include:

- Safer conditions when we keep oil and liquids off the floor.

- Better equipment reliability when we keep it clean and maintained.

- And employees are happier when they have a clean work environment to come to each day.

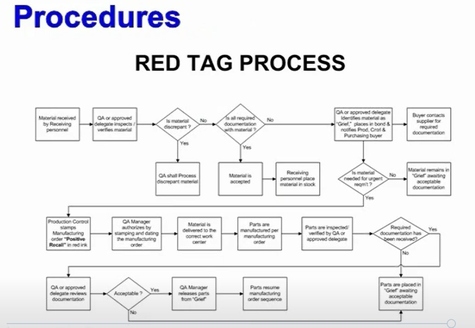

- Standardize means everybody does things the same way when it comes to sorting, setting in order, and shining. There are many possibilities for standardization, and I will give you just a few examples. When it comes to sorting, for example, the same red tag system and procedure should be used. Setting in order can be standardized in the way we mark our floors and the way we locate our tools. Shine can be standardized in the cleaners we use and how we label them, to the way we store them.

- We can also have a standard approach to problem-solving when we encounter problems with sort, set in order, or shine.

- The benefits of standardizing are everything is done the same way by everyone, and everyone understands what to do and how to do it.

- 5s is as difficult to sustain as keeping up an exercise program. If we do not continue exercising, we go back to the way we were before we started. 5s is as difficult to sustain as eating properly, if we do not continue, we again go back to the way we were. Here is an example of sustaining a healthy body, and not sustaining it. Sustained flight, and not sustained flight. If we do not sustain 5s, our company will revert back to the way it was before we started.

- The benefits of sustain are you get to enjoy all of the benefits of 5s forever:

- Less wasted motion

- Less searching time

- Fewer accidents

- Lower costs

- Increased productivity

- Higher quality

- Employee satisfaction

- 5s will help you on your road to lean. many of the wastes that need to be eliminated in manufacturing can be eliminated through 5s.

- Remember, 5s is not easy, but good things never are. The benefits far exceed the hard work required to achieve 5s.

See Video tour of 5s lean training << click link.

Spanish topics: formacion de manufactura esbelta, fabricacion de excelencia, fabrica de la formacion

More Lean Training Video Courses:

Other video training courses:

Industrial Electrical Training Video Series (10 Video Course Set w/ workbook)

PLC Training Video Series (10 Video Course Set w/ workbook)

Please click Contact BIN95 to submit your questions and comments.