(TPM) Total Productive Maintenance Course

Download the TPM Toyota Method PowerPoint today, 81 slides on Total Productive Maintenance Management.

This PowerPoint will help you to investigate if introducing TPM principles will help you reduce lost time on operating equipment to a tune of 30% or better. This is typical for plants that do not already have advanced Preventive Maintenance and Predictive Maintenance (PdM) practices in place. This PowerPoint will also help to ensure you meet the requirements for a Successful TPM introduction to your facility.

TPM is often referred to as "total productivity maintenance" and "total production maintenance".

So we clarify the management method by the following definition ...

Definition:

- Total Productive Maintenance (TPM)

- An equipment management program that emphasizes operator involvement and ownership of equipment performance. The goals of a TPM program are to maximize equipment productivity, maximize equipment availability and make the quality product by eliminating causes of equipment defects, losses, and waste by expanding and engaging the knowledge, skills, and abilities of the front-line people running the process.

Total Productive Maintenance Case Study

Total Productive Maintenance Course PowerPoint's

Prod #: PPT-575S-9I18-29A1 (81 Color PowerPoint slides)

Total Productive Maintenance Management Course outline:

- WHAT IS TPM?

- EQUIPMENT LIFETIME HEALTH

- TPM AND ITS OPERATING RISK REDUCTION BENEFITS

- MEASURING EQUIPMENT PERFORMANCE

- THE IMPORTANCE OF OPERATOR OWNERSHIP OF EQUIPMENT PERFORMANCE

- GETTING TOP-QUALITY EQUIPMENT PERFORMANCE

- REQUIREMENTS FOR SUCCESSFUL TPM INTRODUCTIONN

- TPM REQUIRES CHANGE MANAGEMENT

- A TPM CASE STUDY

- HOW TO APPROACH PLANNING FOR TPM INTRODUCTIONS

You and your personnel need to view this power point if ...

- If you do not already have a successful PM and PdM system in place.

- If you want to learn how TPM can help you.

- If you have a TPM in place but it is not meeting your expectations.

- If you want to increase your facility's throughput.

(After purchase with the 'Add to Cart' button above, you immediately receive an email from PayLoadz with the download link.)

For individuals wanting independent study material and instructors wanting to use in class.

About the Instructor ...

Qualifications: Tradesman Fitter Machinist Professional Mechanical Engineer (1st Class Honors) Project Engineer Maintenance Engineer Master Business Administration Maintenance Manager

Engineering Work History: Nova Machinery – Manufacturer Press Brakes & Guillotines Mike Sondalini Bricklaying - Building Construction Swan Brewery – Beverage Riverton Engineering – Sheet Metal Fabrication Coogee Chemicals – Mining & Agricultural Chemicals Manufacture Lifetime Reliability Solutions – Lean, Maintenance & Asset Life-Cycle Risk Management Consulting

Total Productive Maintenance Course Samples

A sample of some topic headings found within. (81 PowerPoint Slides) …

Total Productive Maintenance PowerPoint Content:

More samples from Total Productive Maintenance management course.

Details of TPM course ...

WHAT IS TPM?

TPM gives Lifetime Equipment Health

• What is Total Productive Maintenance?

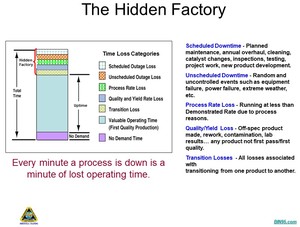

• The Hidden Factory

• The Six Production Losses

• The Seven Process Wastes

• Production Losses and Overall Equipment Effectiveness

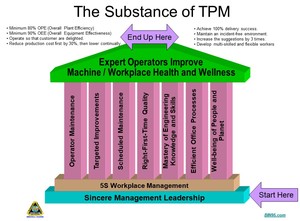

• The Substance of TPM

• The Never Ending TPM Cycle

EQUIPMENT LIFETIME HEALTH

Total Productive Maintenance is … operator driven reliability:

• Need an Equipment Performance Vision

• Match TPM Process to the Vision

• TPM in a Nutshell

TPM AND ITS OPERATING RISK REDUCTION BENEFITS

Purpose of Total Productive Maintenance

• TPM Works by Reducing Risk of Failures

• Multiple Strategies across the Life Cycle

• Value-Added to Equipment with TPM

• Risk Reduction with TPM

MEASURING EQUIPMENT PERFORMANCE

Monitoring Operating Effectiveness

• Purpose of Measuring Equipment Performance

• Overall Equipment Efficiency (OEE)

• Start Measuring Plant Non-Performance

• Production Disruptions Causes Variation

• Pareto Chart the Problems for Focus

THE IMPORTANCE OF OPERATOR OWNERSHIP OF EQUIPMENT PERFORMANCE

Promoting Operator Ownership

• Operator Monitoring and Watch-keeping

• Equipment Behavior – Identifying the Degradation Cycle

• Operators Learn about their Equipment

• Operator Monitoring & Watch-keeping Procedure

• Fact Based Equipment Decisions

GETTING TOP QUALITY EQUIPMENT PERFORMANCE

Failure Preventing Job Procedures

• Accuracy Controlled Expert

• Accuracy Controlled SOPs Prevent Variation

• Including 3T Failure Prevention in SOPs

• Accuracy Controlled Enterprise (ACE)

• 7 Visual Quality Management Tools for TPM Problem Solving

• Make measurement Visual, … turn numbers into information

REQUIREMENTS FOR SUCCESSFUL TPM INTRODUCTION

Identifying TPM Systems and Processes

• Critical Mass of Support

• The People of Successful TPM

• The Culture of Successful TPM

• Best Performance from Multifunctional Teams

• Role and Importance of Supervisors

• Activity 3 – Building Hi-Performance Teams

TPM REQUIRES CHANGE MANAGEMENT

TPM Requires a Change Management Process for Successful Introduction

• Manage TPM Introduction like a Project

• Providing the whole ‘TPM Mix’

• Sustained Resourcing of TPM Processes

• Prototype a TPM Program for Proof of Worth

• Supporting the TPM program

• Change … Do … Learn … Improve

• TPM Champions Needed

A TPM CASE STUDY

Management Support

• TPM Team Objectives

• TPM Team Development

• Identify Current State

• Prioritize Equipment Problems

• Target Key Problems/Set New Standards

• Authorize Proposed Changes

• Improve Documentation/Training

- Return Equipment to Condition/Sustain it

• Measure Improvement/Lock-in Gains

• Second and Third TPM Cycles

HOW TO APPROACH PLANNING FOR TPM INTRODUCTIONS

Planning TPM Introduction: using the Change Management Matrix

• TPM Change Management Requirements

• The TPM Route Map

• Develop Detailed Project Plan & Schedule

(After purchase with the 'Add to Cart' button above, you immediately receive an email from PayLoadz with the download link.)

For individuals wanting independent study material and instructors wanting to use in class.

Related Titles:

Maintenance Planning Scheduling Training Course PowerPoint's

In house Training for Maintenance Reliability and Best Practice

Employee Training and Development with SOP eBook

Enterprise Asset Management System Training PowerPoint's

Industrial Reliability and Maintenance Management Training PowerPoint's

Maintenance Management PowerPoint Download