OEE Reports - Automated Capturing with OEE Software

- Home >

- articles >

- automation >

- oee automated data collection

Moving Beyond Manual Data Collection & Manual Data Compilation

Overall Equipment Effectiveness (OEE) continues to gain acceptance as an effective method to measure production floor performance. Capturing and recording accurate production floor information is critical for producing reliable OEE Reports.

Several production floors are utilizing manual data collection methods for producing OEE reports. This approach leaves room for both inconsistencies and inaccuracies. With manual data collection, there is usually a second step of manually compiling the data. This is most commonly accomplished by entering the information into spreadsheets. This manual compilation step also leaves room for both inconsistencies and inaccuracies.

Another disadvantage to manually collecting data for your OEE reports, like with many maintenance and production improvement plans, is sustainability. The more task-intensive an improvement plan is, the more likely priorities will change, and the OEE initiative will fade away. With an automated data collection system, sustainability is no longer an issue. Once in place, the automated OEE reporting stays in place, and you only need to act on the results.

There are cost-effective automated data collection alternatives to manual data collection that significantly improve the accuracy of OEE reports. Automated capturing and recording of "Availability Information" will be covered in this article. Future articles will address the automated data collection of Performance Rate and Quality Rate.

OEE

OEE = Availability X Performance Rate X Quality Rate

Availability - Percent of scheduled production (to measure reliability) or calendar hours 24/7/365 (to measure equipment utilization) or equipment or line status (to measure the ability to produce) that equipment or a production line is available for production.

Note: Measures the percent of the time the equipment is operational (usually total hours of 24-7-365), divided by the equipment uptime (actual production).

Performance Rate - Percent of parts produced per time frame, of maximum rate OEM rated production speed. If OEM specification is unavailable, use the best-known production rate, or the company can establish a standard production rate.

Note: Performance efficiency is the percentage of time the equipment produces products at its theoretical speed for individual products. It measures speed losses. (i.e., inefficient batching, machine jams)

Quality Rate - Quality as a percent of good sellable parts out of total parts produced per time frame.

Note: Determining the percent of the total output that is good. (i.e., all products, including production, engineering, rework, and scrap.)

Example: 50% Availability (0.5) X 70% Performance Rate (0.7) X 80% (20% Quality Reject Rate results in 0.8 acceptable) = 30% OEE

(Please explore more with this free online OEE calculator.)

OEE Calculator

Example: 50% Availability (0.5) X 70% Performance Rate (0.7) X 20% Quality 80%(0.8) acceptable = 30% OEE

Defining What Is Availability

One of the first steps in initiating OEE reporting is defining the parameters for the elements of OEE for the individual piece of equipment, production line, or entire factory. That clearly defines, documents, and communicates why a piece of equipment or a production area is unavailable for producing the product.

There are three basic approaches to defining availability. The approaches are the percent of scheduled production, calendar hours, and equipment or line status. The schedule production approach defines availability by the production schedule for a single machine, a cell, or an entire production line. The calendar hours define availability as the total time to produce a product, usually 7-24-365. The equipment or line status approach defines availability in terms of the production line or piece of equipment in a state to make the product. All three approaches are valid. The percentage of scheduled production and calendar hours provide a broad view of availability, while the line status approach is much more defined.

Some examples to consider as causes for unavailability are the power to a piece of equipment or whether the production station has personnel in place. The above two causes may not be enough to define the reason for unavailability. You may need to add data inputs recording if there were materials in place or the status of the infrastructure support (such as air pressure for air-driven tools and equipment) as monitoring points to determine if a piece of equipment, a cell, or a production line is available to produce a product. Define availability for each area or a machine with OEE reports. In some instances, the company must monitor more than one element to determine if that single machine or area is considered available.

Automated Data Collection

Setting a goal of capturing availability status information with no manual data collection or compilation for OEE calculations is the first step in improving both the accuracy of OEE reports and reducing the cost of producing the reports. Start with defining what affects availability for various areas of a production facility. Identify the specific data collection points that will affect availability for a given area or unit of equipment. In many cases, there are data collection points already in place. For those monitoring points, you need only to retrieve the existing data. In other instances, the company must install a data collection monitoring device.

For installing new data collection points, a variety of inexpensive sensors are available that, once installed, can capture the measurement of numerous parameters. These sensors can detect flow rate, weight, quantity, motion activity, phases of electrical power, and many other items. The sensors usually come with normally open or normally closed switch contacts. These switch contacts will serve as the data collection points for automated data collection.

Using sensors with switch contact outputs for most monitoring situations is the most straightforward approach for capturing availability data. To monitor equipment, starting with power switches and other functions, it is often the case of adding an extra set of inexpensive contacts to an existing switch on the equipment.

There are other means to capture activity status information, including embedded equipment control software and equipment monitoring software that can capture the parameters for availability. The monitoring approach requires each monitoring point to include a time and date stamp.

Save data collected from the monitoring points to a database for data retention and reporting. The database that captures and records the status information can be a commonly available PC database package such as Microsoft Access. Critical to all data points is that they are recorded with time, date, and location stamps to support the development of OEE reports. Database report writers are used to extract the information to produce OEE reports.

In addition to custom in-house database systems, integrated data collection systems are available with application software packages with complete OEE Reports. Each facility's requirements dictate the OEE data collection system and report design.

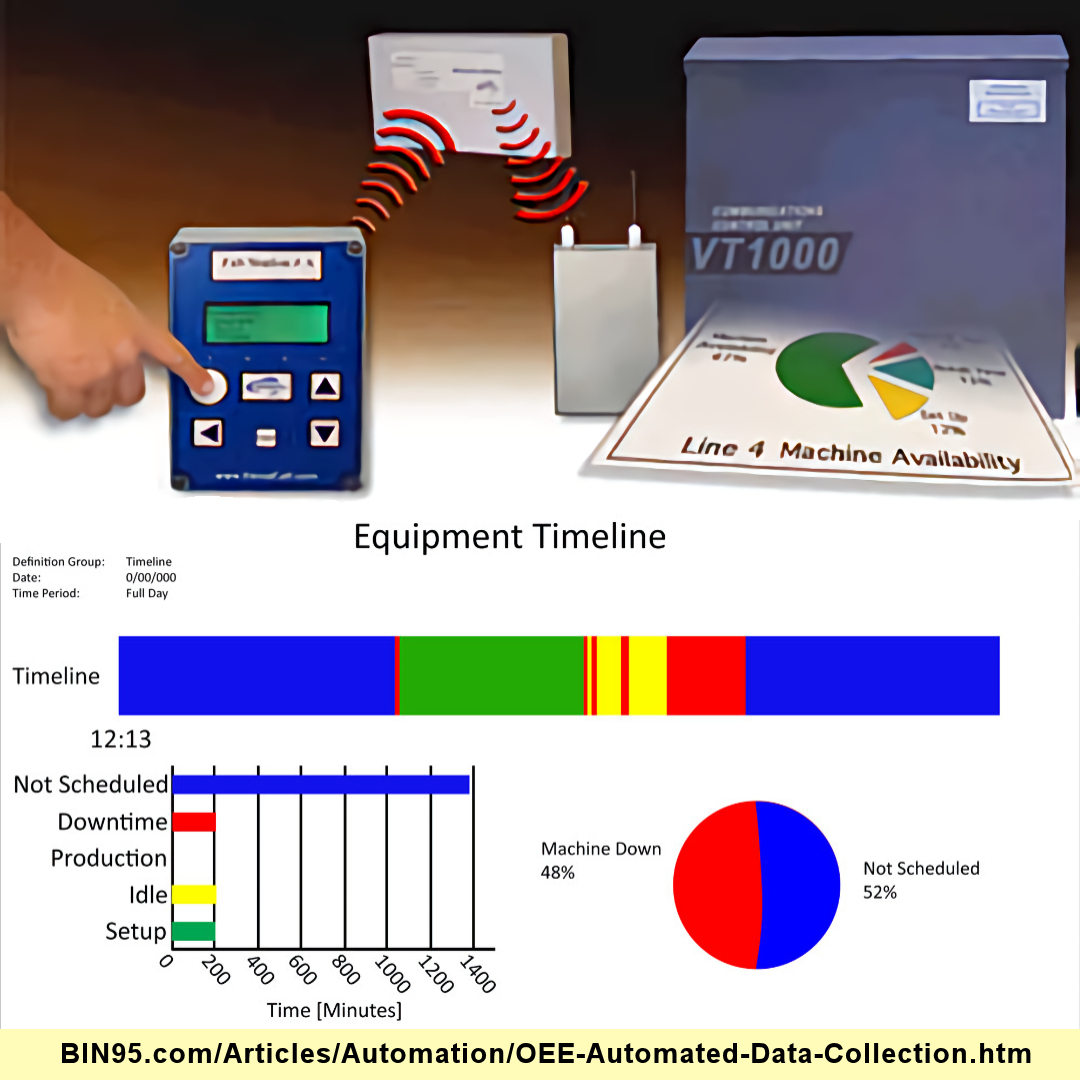

The Wireless Connection

Implementing the wireless LAN or other wireless technologies to capture and transmit available data greatly enhances the data collection system's timeliness, utilization, and flexibility. Over time, hard-wired systems limit the functionality of a data collection system. In the past, wireless technologies did not provide the high reliability required for factories, leaving hard-wired systems as the only alternative. That is no longer true, especially with the introduction of the wireless LAN 802.11g standard and advanced 900 MHz technology. Wireless data collection and transmission systems provide easy reconfigurations of changing production floor layouts or production flow activity changes. Several off-the-shelf production floor wireless data collection systems are available for use on the production floor.

Cost Justification

Implementing an automated data collection system with an integrated database provides immediate financial returns. Automated OEE data collection systems eliminate the labor costs associated with manual data collection on production lines by production personnel and the manual compilation of the data to calculate OEE. The accuracy and integrity of the source data are significantly improved. With more accurate OEE reports, you will make better, financially feasible decisions, resulting in even more significant savings. The timeliness of the OEE reports is also significantly improved with automated data collection. The OEE Reports are usually available for review on the same date it captures the final information element.

About the Author: Bob Giese is the President of VersaCall Technologies Inc., which has implemented wireless factory floor monitoring and communications since 1995. To learn how a wireless system would benefit your location, email sales@versacall.com