- Home >

- articles >

- maintenance-management >

- incumbent worker training reimbursement

Worker Training Reimbursement Programs

Some are better than next level jobs workforce ready grants.

Some of our training customers get reimbursed in full or in part, the cost of our training Site Licenses or on-site PLC training using their local state incumbent worker training program, retraining tax credit, next-level jobs workforce ready grant, and other workforce training grants. As many small and midsized manufacturers may not take advantage of their local state incumbent worker training programs, I wrote this article to increase awareness.

Here I will focus on the incumbent worker training programs and retraining tax credits. As next-level jobs workforce-ready grants and other grants are more cumbersome and more importantly greatly limited in what training qualifies. The simplified difference between the two groups of training reimbursement programs is that with most state training programs, the manufacturer decides what training works best for them and then seeks approval from the state program. In contrast, for the next-level jobs workforce-ready grants and other grants, the manufacturer has only a finite limited selection of pre-approved topics/providers to choose from. Manufacturers can also partner with local colleges to design a custom course, but besides the delay, a new course the first time out the door can be less than optimum in some situations when compared to tried and tested courses by subject matter experts in the field and topic being taught.

Incumbent worker training, upskilling, and re-training cost:

Employee turnover comes with a hefty price tag. Studies have shown that for positions requiring specialized skills and education, the cost of attrition can be as high as 213% of the employee's annual salary. This means that the expenses associated with losing an employee earning $80,000 per year could range from $40,000 to a staggering $170,400. These costs include recruitment expenses, employee training costs for new hires, lost productivity during the learning curve, and potential disruptions to the team's dynamics.

One of the driving forces behind the urgency of upskilling employees is the widening skills gap. The rapid digital transformation has resulted in specialized jobs that require specific expertise. As technology continues to evolve, employees must keep pace with these changes to remain relevant and productive. Without the necessary skills, employees’ risk being left behind in the race for success, and companies may struggle to maintain their competitive edge.

Recognizing the importance of bridging the skills gap, organizations are now taking proactive measures to invest in worker training programs. The average organization spends $1,280 per employee on formal learning according to the Association for Talent Development’s 2022 State of the Industry report. On the other hand, 60% of employees across the globe want additional guidance on how to continue their education and learning within their careers. (Bright Horizons, 2022) These statistics show that incumbent workforce training is a crucial aspect of scaling a skilled and knowledgeable workforce, allowing companies to stay competitive in today's dynamic business and technology landscape.

By providing their workforce with opportunities to acquire new skills and knowledge, companies can ensure their adaptability and relevance in the digital era. However, the cost of training programs for employees can be a significant burden for manufacturers, especially for small and medium-sized enterprises.

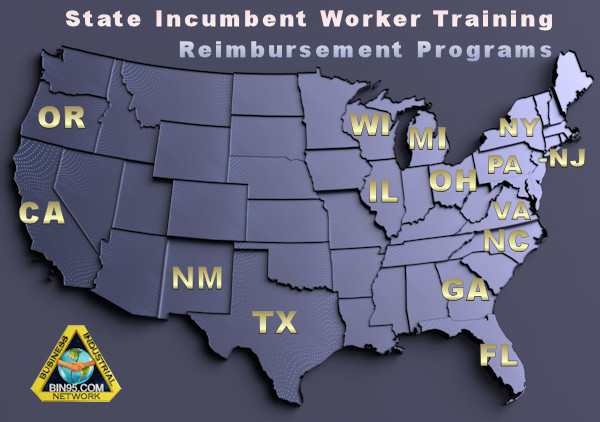

Incumbent Worker Training Reimbursement Programs by State:

To alleviate the strain of corporate training costs on manufacturers and encourage investments in employee training, several states in the United States have implemented Worker Training Reimbursement Programs. These programs aim to support manufacturers in upskilling their employees by offering reimbursement for eligible corporate training costs. Employers are in some cases required to provide their training program cost estimates to the appropriate state agencies. Below you will find some notable incumbent worker training programs to explore.

California Workforce Training

The Employment Training Panel (ETP) in California is dedicated to supporting employers in expanding the skills of their workforce. This program provides funding to offset the cost of training, ultimately boosting the competitiveness of manufacturing in the state. Employers may apply for funding to pay staff training expenses, which will boost output and promote manufacturing expansion.

Florida Workforce Training

Florida has an employee training reimbursement program known as the Florida Incumbent Worker Training (IWT) Grant offered by CareerSource Florida. Employers can explore training reimbursement options and funding opportunities to support their workforce development efforts.

Georgia Workforce Training

The Georgia Retraining Tax Credit (RTC) offers tax credits to manufacturers that provide qualified training programs for their employees, helping offset some of the employee training costs incurred. manufacturers can enjoy a 50 percent tax credit on their direct training expenses, with up to $500 credit per full-time employee, per training program.

Illinois Workforce Training

The Illinois Incumbent Worker Training (IWT) programs help local employers develop and implement training programs for current employees who need new or upgraded skills in order to retain employment. Based on the size of the company, up to 100% of the costs of training can be reimbursed through the program.

Michigan Workforce Training

The Going PRO Talent Fund (Talent Fund) makes awards to employers to assist in training, developing and retaining current and newly hired employees. Training funded by the Talent Fund must be short-term and fill a demonstrated talent need experienced by the employer. Training must lead to a credential for a skill that is transferable and recognized by industry.

New Jersey Workforce Training

The New Jersey Incumbent Worker Training Grant, Workforce Development Program (UPSKILL) provides funding to help employers upgrade workers’ skills. The funds will be competitively awarded to employers within New Jersey to reimburse up to 50% of the cost of training incumbent, front–line employees to meet current and future occupational skill requirements needed for available high-wage, middle- and high-skill jobs.

New Mexico Workforce Training

The New Mexico Job Training Incentive Program (JTIP) funds classroom and on-the-job training for newly-created jobs in expanding or relocating manufacturers for up to 6 months. The program reimburses 50-90% of employee wages. Custom training at a New Mexico public educational institution may also be reimbursed. Since 1972, JTIP has supported the creation of more than 1,600 training projects.

New York Workforce Training

The New York Employee Training Incentive Program provides 50% refundable tax credits to New York State employers for skills training that upgrades or improves the productivity of their employees. Manufacturers can also receive tax credits for approved internship programs that provide training in advanced technology, life sciences, software development, or clean energy.

North Carolina Workforce Training

North Carolina's Incumbent Worker Training Program is designed to make a difference in the manufacturer's bottom line, whether the organization is creating jobs, investing in new machinery and equipment, or streamlining processes for efficiency. Incumbent Worker Training Program resources may support training needs assessment, instructional design, development and delivery.

Ohio Workforce Training

Ohio TechCred helps Ohioans learn new skills and helps employers build a stronger workforce with the skills needed in a technology-infused economy. No matter what industry you work in, technology is having an impact on the future of your manufacturing company and the nature of your work. Whether it's a certification course or a specialized workshop, eligible employers and employees can benefit from this initiative.

Oregon Workforce Training

Oregon On-the-Job Training Program (WorkSource) can help you grow a skilled workforce and increase the skills of your current workforce with apprenticeships, internships, and training options, helping to pay for the costs of training. Also, get reimbursed for up to 50% of a new hire’s wages (up to $5,000) during their first few months of on-the-job training.

Pennsylvania Workforce Training

The Workforce and Economic Development Network of Pennsylvania (WEDnetPA) does allow manufacturers to determine their own training needs which qualifies them for this list, but they are limited to only providers within their own state. They do allow the manufacturer to decide how and where they will receive their desired training (onsite, offsite, or online).

Texas Workforce Training

The Texas Skills Development Fund is an employer-driven program aimed at providing customized training solutions to manufacturers. This program assists manufacturers and trade unions by financing the design and implementation of customized job-training projects. This fund successfully merges the manufacturer's needs and local customized training opportunities into a winning formula to increase the skills levels and wages of the Texas workforce.

Virginia Workforce Training

The Virginia Jobs Investment Program (VJIP) is a discretionary program that provides funding to companies creating new jobs or experiencing technological change to reduce the human resource development costs for new companies, expanding companies, and companies retraining their employees.

Wisconsin Workforce Training

Wisconsin Incumbent Worker Training Grants allow manufacturers to select the training to be provided to their employees. Surprisingly their program is slightly more limited than other states listed here, but the manufacturer may be reimbursed between 25% and 75% of the costs of training their workers dependent upon training outcomes.

The Benefits of Incumbent Worker Training Reimbursement Programs:

These state programs not only ease the financial burden on manufacturers but also foster a skilled and adaptable workforce. By encouraging employers to invest in incumbent worker training, the programs contribute to reducing employee turnover rates, as well-trained and upskilled employees are more likely to stay loyal to their current employers. This, in turn, leads to increased productivity, efficiency, and competitiveness for manufacturers. Additionally, a skilled workforce attracts potential investors and enhances the state's overall economic growth.

Commentary:

The limited, pre-approved approach most grants take, removes the competitive driving force that normally results in a company's ability to shop for the best for less, generally speaking. With our training company [BIN95] we see each year most companies who are aware, seeking to reduce their training costs using their state incumbent worker training program to purchase our training (On-Site PLC training and Automation Training Site Licenses), and with colleges not being a manufacturer, using grants to purchase from us. I have seen the jumping through hoops and deadlines some of our customers had to struggle to make with grants and can understand how that approach can reduce the quality of decisions and training. For something as important as training, rushing is the last thing you want to do.

In conclusion, incumbent worker training reimbursement state programs offer a win-win situation for both manufacturers and their employees. The abovementioned efforts are just a few of the state programs implemented to assist with the cost of training programs for employees. Companies benefit from reduced corporate training costs and an empowered workforce that can adapt to the demands of the digital age. Employees, on the other hand, gain valuable skills and knowledge that enhance their career prospects and job stability. As the manufacturing industry continues to evolve, investing in employee training and taking advantage of state programs to offset employee training costs is no longer just an option but a necessity for success in the 21st-century marketplace. By working together to bridge the skills gap, manufacturers and states can shape a promising future where innovation and productivity go hand in hand with a skilled and empowered workforce.

Sources:

ELM Learning. (2022, May 24). How much does employee training really cost?

Kovacs, J. T. (2018, March 19). Employee Turnover: Can Employers Recoup Investments In Their Employees? | The Labor Dish.

Simplilearn. (2023, February 14). Employee Tuition Reimbursement: How Does it Work and Tips.

Cornett, J. E. (2016, October 26). Rules for company tuition assistance. Small Business.Chron.com