- Home >

- articles >

- maintenance-management >

- manufacturing automation sustainability

Manufacturing Automation Sustainability

Manufacturing automation sustainability significantly improves with maintenance automation training.

Automation eliminates inefficiencies that can negatively impact the business and the environment. Automation technology can help to manage energy requirements and limit waste.

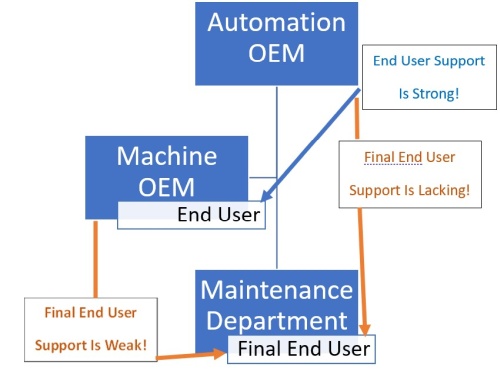

A sustainable automation design approach focuses not just on humans but, just as importantly, on the final end-user. The end-users of automation control are the plant professionals who must maintain and modify the equipment for years to come.

With that end-user in mind, employee training is critical to machine design sustainability. While employee training affects all areas of the sustainability accounting standards related to engineering (SASB Standards), it is a more critical consideration for automation control.

Additionally, many sustainability solutions will significantly reduce downtime and increase profits. You know what they say about sustainability; it is a win-win-win for everyone!

Below, we'll explore two case studies. While there are several opportunities for automation sustainability improvements, these two are more common and significantly impact the company and the environment's sustainability. The similarity between the two case studies is that both focus on the final end-user of the automated equipment.

OEM Customer Training Sustainability Case Study: While most industrial equipment manufacturers provide some operator training, few provide adequate automation control-related training for the customer's maintenance department. Some OEMs see customer training as a revenue source in their business model. Others focus on service as an additional revenue stream, not providing training above the operator level.

Less customer training may result in more service call revenue but at increased downtime costs for their customers. While it may be sustainable for the OEM, it is not for their customer or the environment, with the increased carbon footprint of traveling field service techs.

World-class OEMs realize that adequate maintenance training on their machines or systems' automation control intricacies reduces their warranty period costs. Less service tech travel, downtime, quality issues, and other metrics defined in True Downtime Cost tm, significantly increase sustainability. Remote service and support have helped combat this sustainability issue with less travel. Still, they come at a significant security risk to the customer.

OEM customer training impacts most of the areas identified in the SASB Standards for Engineering. The most notable areas are environmental, safety, lifecycle, climate impact, and business ethics. With many OEMs today, providing the customer's maintenance department with training often only consists of maintenance looking over the shoulder of the start-up tech. That has got to change.

Sustainable Automation Control Design Case Study: As with the customer training section above, this automation control design advice focuses on the customer's maintenance department, the end user for the life of the equipment. After all, the sustainability impact of reducing downtime should be clear. Anything in your design that can make the maintenance department's job easier will increase sustainability.

Items like providing customers with a well-descriptored PLC/PAC program, training, and all maintenance documentation are apparent. However, increasing machine learning and troubleshooting automation programming is an area that needs improvement—for example, incorporating Predictive Maintenance (PdM) in your automation program. As is writing PLC programs with the end-user (a maintenance electrician) in mind, making it more user-friendly for them.

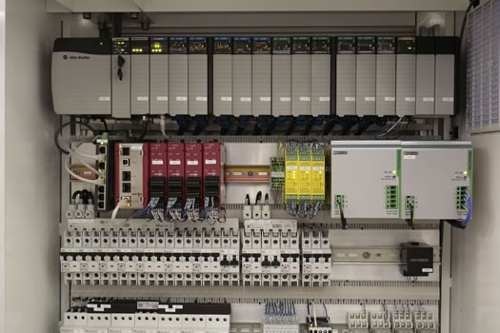

The programmer may prefer writing an automation control program in fewer lines with complex structured text. But the environmental, safety, and lifecycle impact of the massive increase in service calls, downtime, and quality are unsustainable. The same goes for the control panel design. The more you design your panel with the maintenance end-user in mind, the more sustainable it will be.

Below are a few things I listed in an article I wrote for Control Design.

- Have an outside-the-panel PLC communication port and fused 120-V outlet.

- Include in HMI/SCADA or panel indicators: Warnings triggered by bits for battery dead, forces in place, PLC fault, all e-stops, and disconnects (aux contacts needed).

- Always break up logic into organized sub-routines for user ease of understanding and navigation.

- Go the extra mile and have automated warning alerts if neutral-to-ground voltages exceed 2 Volts.

- Consider panel-temperature monitoring, particularly an over-temperature warning.

- As part of the PdM automation code, Monitor MTBF/ABF for crucial components and indicate warnings in the controls as the component approaches its MTBF/ABF.

These lead to improved operational efficiency and contribute to a more sustainable approach to manufacturing. Designing energy-efficient machines, utilizing eco-friendly materials, and having minimal environmental impact is essential for achieving long-term sustainability goals.

Ultimately, the intersection of sustainability and automation presents an opportunity for machine designers to make a lasting impact on our planet. By embracing sustainable design principles and leveraging automation technologies effectively, they can drive positive change within industries while minimizing their environmental footprint.

A sustainable automation design approach focuses not just on humans but, just as importantly, on the final end-user. The end-users of automation control are the plant professionals who must maintain and modify the equipment for years to come.

OEMs who would like to cost-effectively empower their customers by making automation control training available; consider the BIN95 Enterprise Licensed Automation Course Bundle.