Maintenance Planner Scheduler Job Description

- Home >

- articles >

- maintenance-management >

- preventive maintenance planner

The Planner/Scheduler Job is Much More Than Only Being a Preventive Maintenance Planner.

Follow Ted as he learns about the Maintenance Planner Scheduler job description in the excerpt below from the full Maintenance Planning and Scheduling course PowerPoint download. The course PowerPoint starts out teaching Ted that the Maintenance Planner Scheduler job opening is much more than being a preventive maintenance planner or being a maintenance repair person. As you will learn here, the potential planner needs to learn the big picture first.

Maintenance Planner Scheduler Notes:

Usually, a person from the maintenance crew is asked to move into maintenance planning. Often it is a person who knows the plant and equipment well. The thinking behind the selection is that this person will know what to do in the planner’s role because they are so experienced with the machinery. But planning has got nothing to do with how skilled one is with their hands when working on machines. Planning is about being methodical, disciplined, forward-thinking, and an excellent organizer. If you are not strong in all those four requirements, then get exposure and experience in the weak areas so that you become more aware and able in doing them well.

The best training is hands-on training. Do a thing, and you will learn it faster and more thoroughly than reading or hearing about it.

To be good, really good, at a job, any job, you have to know everything about it. Things like - why it is done that way, what was its history, what works and what causes problems, how to fix the problems if they appear. When you become an expert everything is easy. But that takes exposure to situations along with discovering the best way to handle them. It requires that you learn all that you can from others who do it well, and from what is written by others, about what you want to be good at.

I remember talking with a guy that I had worked with for years and he surprised me by saying he was a competition rifle shooter. When he talked to me about it, his passion for target shooting welled up from him. He said that to be a good competition shooter you had to assemble your own bullets. The store-bought bullets varied too much in performance. He described how he measured the gunpowder into the cartridge, it had to be just the right weight to get the right trajectory. Not enough and the bullet went low, too much and the rifle kicked high. He told me how the bullet tumbled its way to the target and as it rolled end over end any turbulence in the air would cause it to stray from the target. He said how terribly important it was to adjust the sighting for the strength of the crosswind blowing. He described with delight how he lined up the target and virtually ‘coached’ the bullet to the bull's-eye. He knew everything there was to know about his sport and the requirements to master it. He was an expert marksman.

You will need the same passion and dedication to become a ‘Top-Gun’ Maintenance Planner Scheduler.

Maintenance Planner Best Practices:

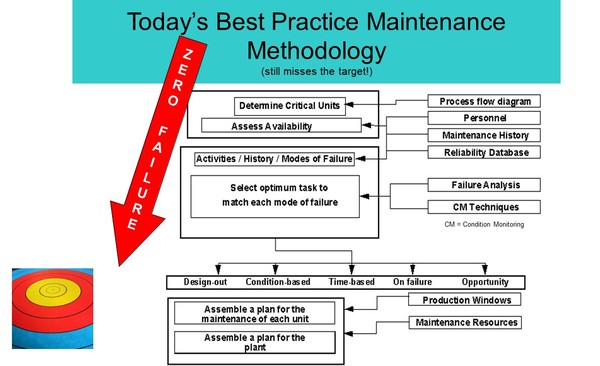

Maintenance methodology today has progressed to the approach shown in the slide.

We identify the way equipment can fail and the risk the failure has on the business. Then we put in place appropriate methods and techniques to either prevent failure or minimize its consequences. This requires cooperation between people in order to make sure maximum quality product is made, while also keeping machinery in top working order so that quality product can be safely and surely produced.

The balance between production and production capability is an always moving requirement that is actively managed by the people in the organization through the use of quality management systems and processes.

Unfortunately, today’s maintenance management does not work. I can say that because production equipment continues to fail. If it did work there would be zero failures. There is something vital missing in our understanding and practice of doing maintenance. Without the missing ingredients, we can never taste the success of getting zero failures.

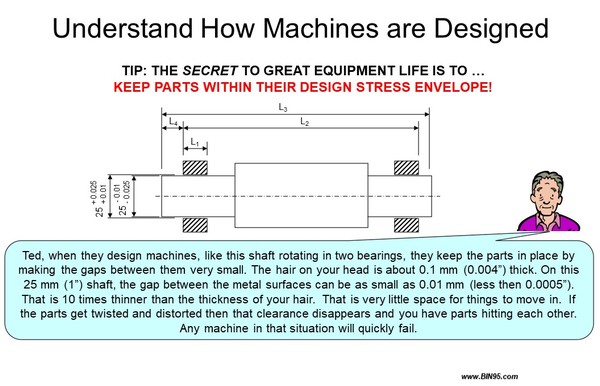

How to Design Machinery:

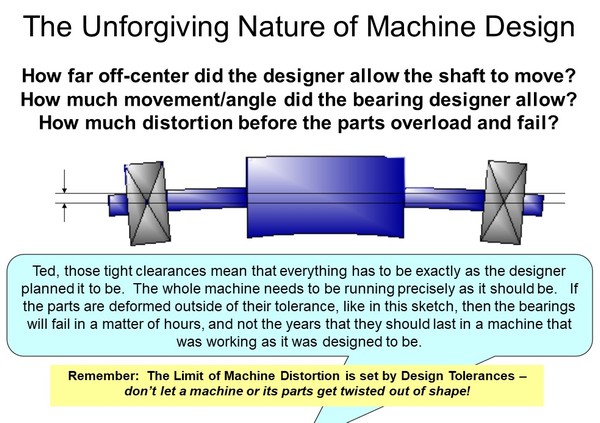

In the sketch the bearing diameter ranges from 25.01 to 25.025 mm. Shaft diameter ranges from 24.975 to 24.99 mm. Bearing to Shaft diametric clearance ranges from a possible low of 0.02 mm (0.0008”) to a maximum of 0.05 mm (0.002”) So a radial movement of 0.01 (0.0004”) to 0.025 mm (0.001”) will cause a clash of shaft and bearing.

There is no forgiveness in machines when they are pushed and distorted beyond their design capability. Understand that machines need to be cared for in-service by using them, and looking after them, within the limits, and in the ways the designer expected. Understanding the importance of being aware of how machine designers expected the equipment to be used is a common knowledge and experience a maintenance repair person gains. Thus it is one of the attributes that make them a good candidate for the maintenance planner job role.

... The Importance of Machine Design Tolerance:

As soon as a machine part deforms outside of its tolerance limits it is on the way to premature failure. Plant, machinery, and equipment can only be expected to be reliable if kept within the design stresses and the internal and external environmental conditions it is designed to handle. Once the stresses or environmental conditions are beyond its capability, it is on the way to an unwanted breakdown at some time in the future.

Maintenance Planning Purpose:

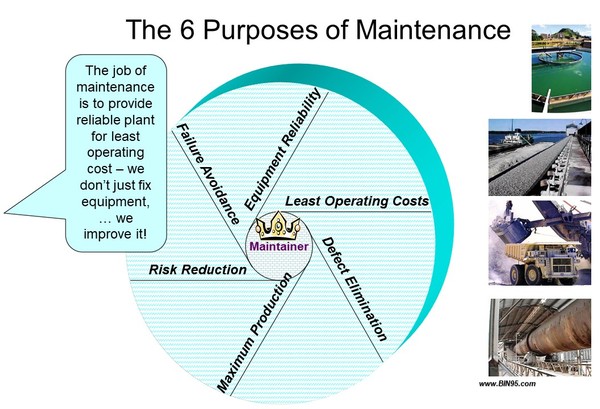

Maintenance has a greater purpose than simply looking after the plant and machinery. If that was all that was necessary then maintainers would only ever fix equipment and do servicing. In today’s competitive world, maintenance has grown into the need to manage plant and equipment over the operating life of a business’ asset. It is seen as a subset of Asset Management, which is the management of physical assets over the whole life cycle to optimize operating profit.

There are at least six key factors required of maintenance to achieve its purpose of helping to get optimal operating performance. These are to reduce operating risk, avoid plant failures, provide reliable equipment, achieve the least operating costs, eliminate defects in operating the plant, and maximize production.

In order to achieve these, all people in engineering, operations, and maintenance need great discipline, integration, and cooperation. There needs to be an active partnership of equals between these three groups where the needs and concerns of each are listened to and integrated into the maintenance planning work.

Life Cycle Planning:

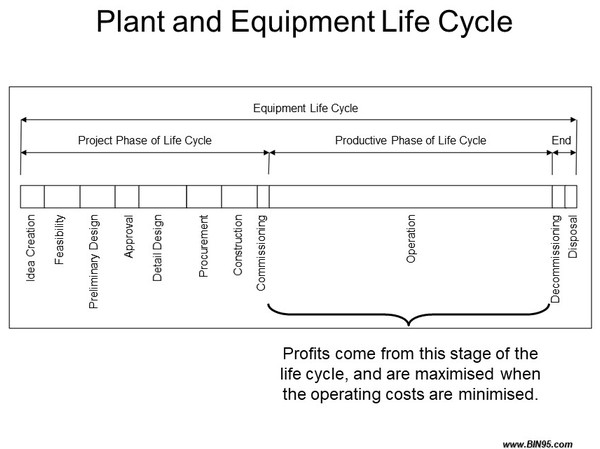

The plant and equipment used in an enterprise have a life cycle. It starts with the recognition of an opportunity, then progresses to feasibility and approval. If the idea is found worthwhile a full design is developed, plant and machinery are purchased, installed, and put into operation. The vast majority of the life cycle is the operation phase, and this continues until the plant and equipment are eventually decommissioned and disposed of.

A business is started with the expectation that the investment made to get into operation will return a profit within a specified time. The profit is only generated during the operating phase of the life cycle. The more profitable the operation, the sooner the investment is returned, and the sooner an unencumbered income stream is created. If we want to maximize operating profit we must keep the operation performing at the throughput approved when the investment decision was made, while having costs no greater than those expected. One of those costs is the repairs and maintenance of the plant and equipment.

... Life Cycle Planning Reduce Cost:

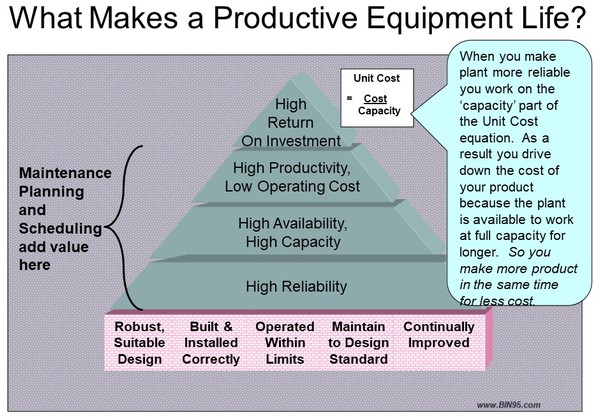

Well-performing businesses return their investments and generate good profits. The profitability from plant and equipment depends on the difference between how much it costs to operate and produce a product from them, and the selling price of the product. Equipment that runs without failure, at high capacity and product quality, with good efficiency and little waste will produce higher Return on Investment (ROI). To achieve this ideal it is first necessary to have selected well-designed equipment suited to the task and situation, properly installed to high standards, run within design limits, and cared for to the standards that retain design performance. If any of the four foundation requirements are missing you will have a problem plant.

The successful operations and maintenance planners, work hard to sustain a high capacity from their plant AND for low costs. This means they make a quality product, with a low unit cost that they can sell below competitor's prices, and so they win greater market share, while still having good profits.

Maintenance Planning and Scheduling 'Big Picture':

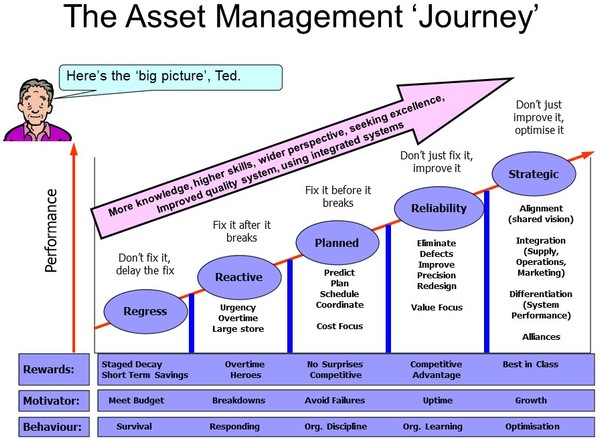

There is a ‘big picture’ to see and understand if you want to be a successful maintenance planner scheduler. This ‘vision’ is the journey to operating excellence. If we want to create outstanding businesses that satisfy all stakeholders, including ourselves, we will need a business that works like a well-designed, operated, and cared-for machine. It runs reliably, at full capacity with no problems. To get to that point means the entire operation and business are fully coordinated and integrated so that everyone helps everyone else perform at world-class levels.

The conceptual operating model in the slide comes from work done by DuPont in the 1990s. It is known as the ‘Stable Operating Domain Model’. It shows the stages that an industrial business must pass through to achieve operating excellence. Most businesses start at the reactive stage where they wait for things to go wrong. The better businesses move to the planned stage where they are organized to minimize operating failures. Good businesses change to become reliable organization that prevents problems from starting. The ultimate businesses are looking for perfection, where all that they do supports ideal performance.

We can take DuPont’s model for developing operating excellence as our own. It has worked for many other companies. It explains what must be done to travel the journey to world-class operation. What DuPont does not talk much about is how they got their people to make the journey. Because it is only when people’s beliefs and values change that a stable domain becomes established.

With the power of hindsight, it can be seen that DuPont set in place new, higher benchmarks and standards and made it clear that their people needed to work towards them. They brought their people to higher levels of understanding, expertise, and skill.

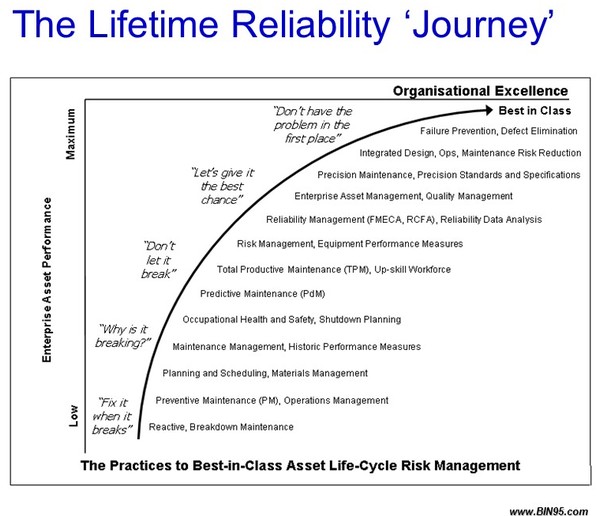

... Planning for Lifetime Reliability:

Here is another ‘view’ of the ‘journey’ to best-in-class. This ‘map’ makes it clear what reliability ‘steps’ to take on the maintenance planning and scheduling best practices journey too.

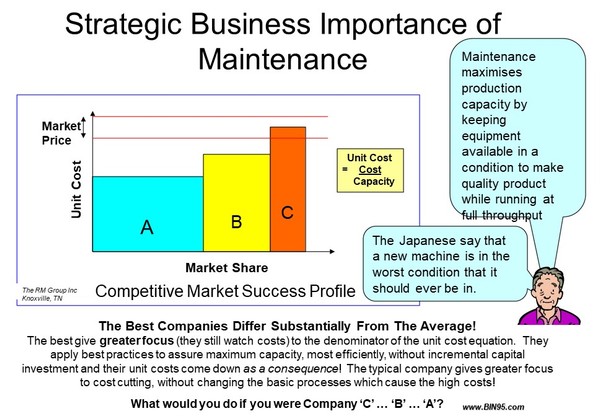

What are the Benefits of Maintenance:

This concept is one that Ron Moore of the RM Group uses to explain why the best businesses perform so well. It shows a competitive marketplace of three companies and their relative market share and product cost. Each company remains in business for different reasons. Company C has high costs but retains customers because it does special requirements for them. Company A is a low-cost producer and sells to customers based on the least price. Company B is in a difficult position because it neither provides for special needs nor has the best price. It exists because Company A cannot supply the total demand of the market.

The real message in the slide is that a company needs to focus on achieving the least unit cost of production if it wants to win the marketplace. The equation for Unit Cost shows this can be done by either reducing the cost of production or by increasing the capacity to make more products for the same cost of production. However, those companies that focus on cost reduction risk compromising their product quality and marketplace reputation. They will buy cheaper raw materials, try and use incompetent staff, slash maintenance, and the like. Some companies will not even have a Maintenance Planner Scheduler, adding that role to the many hats the maintenance manager wears.

But those companies that work to increase their plant capacity achieve lower-cost products because they make more products for the same cost of production. They increase equipment reliability, they increase the skills and knowledge of their employees, they use risk reduction practices, like Accuracy Controlled Enterprise 3T (Target-Tolerance-Test) procedures, throughout their business processes.

What would you do if you were Company 'C' ... 'B' ... 'A'?

Companies profits 15 times the 'Top-Gun' maintenance planner salary!:

Selling products does not make money for a business. The business only makes money if it can sell its products for a profit. If you have to sell at a price because competitors are selling at that price, then you may be selling at or below cost. The business won’t last long if it sells its products for less than it can make them.

To learn about the profits of maintenance planning and scheduling and more that the Maintenance Planner Scheduler needs to know, download the 229 slide Maintenance Planner Course PowerPoint today. Also to see more future sample releases from our courses, follow us on social media. (Icons on the left or bottom of this page.)