Bearings and Lubrication Explained

Applied Tribology: Bearings and Lubrication Explained

By Mike Sondalini

This whitepaper will help the beginner understand Bearings and Lubrication from Mike's decades of experience in applied tribology. It includes real-world knowledge, such as the six secrets of trouble-free lubrication success and converting from bearing oil bath to greased lubrication. It is 19 pages long.

If you are familiar with Mike's series of mechanical engineering whitepapers here, you know he also sprinkles some valuable design tips in his works. Yet he keeps it simple, making this bearing and lubrication PDF download great for engineering students and maintenance personnel. The reader will gain a good understanding of oil lubrication systems for bearings and bearing lubrication procedures.

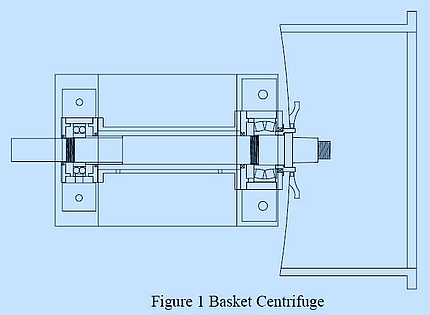

The 'Converting from oiled to greased shaft roller bearings' section is a must-read. Converting shaft bearings on a basket centrifuge from an oil bath to grease lubrication involved changing the method of shaft sealing. Roller bearings can be lubricated with oil or grease, but grease has distinct advantages in some applications.

Bearings & Lubrication Explained - Contents:

Protecting bearings from dust and water.

Protecting bearing from dust. Protection methods like labyrinth rings, rubber seals, felt seals, and shaft mechanical seals are described. Choosing the appropriate shaft seal and seal configurations to protect against dust ingress is critical. Numerous shaft seal designs suited to dusty conditions are reviewed.

Grease - the right type of lubrication in bearing.

The classification, selection, and application of greases. Greases are designed for specific applications, and if used in the wrong service, they will not be effective. Compare the properties of greases and check that those used in your equipment are suited to the service.

Agitator shafts steady bearing problems.

Vertical tank agitator bearings are required to take both radial and thrust loads. To protect the gearbox, intermediate bearings on the shaft are commonly installed. If these bearings are exposed to process vapors, special care is needed to protect them from contamination and ensure adequate lubrication.

Angular contact bearing use.

They are used on shafts that encounter axial forces or combined loads (both axial and radial forces). Examples are centrifugal and helical rotor pump shafts and helical and worm gear shafts in gearboxes. Their design only permits axial forces in one direction. Alternating axial loads must be installed as a bearing set to accommodate the forces from both directions. When set back to back, and less so when put face to face, they act to stiffen the shaft and handle more significant bending moments such as overhung components or high midpoint shaft loading.

Spherical roller bearing use.

These bearings are popular because they can take very heavy loads and are self-aligning. Their design allows them to take combined loads in both the radial and axial directions acting together.

Converting bearings from oil bath to greased lubrication.

The conversion of shaft bearings on a basket centrifuge from oil bath to grease lubrication involved changing the method of shaft sealing. Roller bearings can be lubricated with oil or grease, but grease has distinct advantages in some applications.

How o-rings work.

Properly designed o-ring grooves and properly installed o-rings stop the passage of pressurized liquids or gases. O-rings are made of elastomeric materials such as rubber and plastics. Their greatest sealing advantage is their flexibility while being deformed under pressure. They deform under pressure and then return to their original shape once the pressure is removed.

Oil - how clean does it have to be?

Clean, dry oil can extend equipment life between failure up to 8 - 10 times the normal operating life. Timken, the bearing manufacturer, reports that reducing water levels from 100 PPM (parts per million) to 25 PPM doubles bearing life. British hydraulics research indicates that if solids contamination with particles larger than 5 microns (0.005 mm or 0.0002") is reduced from 5,000 - 10,000 particles per milliliter of oil to 160 - 320 particles, the machine life is increased 5 times.

The 6 secrets of trouble-free lubrication success.

Lubricants can only reduce friction if their immediate environment sustains their lubricating properties. Once the operating conditions are known, a suitable lubricant with the right properties can be used. When the lubricant is in place, it is necessary to maintain the environment and the machine to the specified design standards and protect it from changes to the design conditions. Six key factors must be addressed for a trouble-free life where grease or oil lubrication is used on machinery.

Lubrication cleanliness & filtration.

When gearbox oil becomes contaminated, bearing operating life rapidly decreases. Metal particles, dirt, sand, oxidization products, etc., must be removed from the oil before they gouge and tear up the finely-tolerant machine parts. Oil replacement, contamination prevention, and oil filtration are common practices religiously adopted by the best in the equipment reliability management business. This article explains the acceptable requirements for successful contamination control to ensure long, trouble-free equipment life.

Gain valuable insight and understanding; get your copy of Bearings & Lubrication Explained today!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$12.50

An Excerpt From Bearings & Lubrication Explained

"BEARING BREATHERS"

When protecting bearings from dust, you always want to consider another crucial area. A breather is used to let hot air out of a confined space and then to let the air back in when it cools down. Enclosed bearings get hot when operating and cool down to ambient temperature when not used. The air drawn back into the space must be dust and moisture free. A breather on a bearing housing or bearing housing enclosure allows moisture and dust to ingress into the bearings, causing premature life failure.

Often, a breather is insufficient and should be replaced with a low-micron air filter that removes dust particles in two microns and larger in size. Protect the breather or filter from water spray and damp conditions (ban hosing down if possible) with a shroud or by using an extension tube going into a clean, safe environment. Make sure the breather tube cannot be crushed closed by accident.

Please contact us with any questions.