Electric Motor Maintenance Repairs

Electric Motor Maintenance and Repairs Whitepaper

By Mike Sondalini

This Electric Motor Maintenance and Repairs Whitepaper covers maintenance topics like electric motor greasing, bearing vibration detection, and vee-belt and chain drive maintenance. Mike also has sections on the rarely discussed topics about the effects of process changes on electric motors and plant layout improvements for maintenance. Included is the infamous 6 secrets of trouble-free lubrication success section too. 21 pages.

Mike also gives the reader the twelve most common causes for electric motor repair and has a section on how the correct 3-phase motor overload protection can save your process and manufacturing plant. Understanding the basics of electric motor variable speed drives operation is important, especially when your electric motor not running at full speed is the problem. This whitepaper should be of use to anyone providing electric motor services.

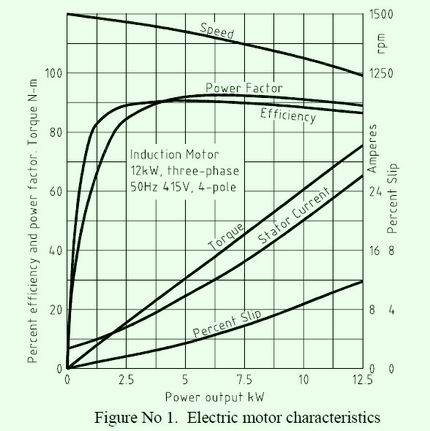

Because an electric motor rotates it can only deliver torque (a turning force) through its shaft. It also means that an electric motor will experience all equipment loads on it as torque. The motor shaft will turn and the attached equipment will move only as long as the motor can generate the required torque. Figure No. 1 shows the performance curves for a squirrel cage induction motor (the most common 3-phase AC motor). They show that as the rotor speed drops because of an increased load the rotor slips more, the torque generated rises and the current draw in the stator increases.

Electric Motor Maintenance and Repairs whitepaper - Contents:

Electric motor greasing - use the right one for the job.

The classification, selection, and application of greases. Greases are designed for specific applications and if used in the wrong service they will not be effective. Compare the properties of greases and check those used in your equipment are suited to the service.

Bearing vibration analysis.

Roller-bearing vibration measurement is one of the major condition monitoring tools in regular use. By measuring the velocity, acceleration, and frequencies emitted from a rolling bearing it is possible to tell its condition and the likelihood of imminent failure. The technology is well-established and well-proven but requires a good understanding of equipment vibration characteristics before a user can draw good interpretations from the results.

Electric motor variable speed drives operation.

Alternating current electric motor speeds can be changed by the use of a frequency converter. This device changes the frequency of the alternating current to the motor. This then changes the rotating speed of the motor's internal magnetic field. The speed of the rotor responds accordingly and so allows for variable speed control of connected items. When these devices are used there are several issues that need to be addressed to ensure the successful selection and long-term operation.

Effect of process changes on electric motors.

This section explains the effect of changing process loads on AC induction electric motor performance. The motor's behavior is a response to the load imposed on it by the equipment connected to it. The equipment's behavior is itself a response to the duty and service it has to perform. Where the equipment duty and service are adjustable by the operator or fluctuate as the process changes, the motor will react to those changes. When the changes are so excessive that they are beyond the motor's ability to handle them the motor stops and the equipment or process stops with it.

Equipment and plant layout for improved maintenance.

Equipment reliability studies show that the likelihood of failure increases the more often machinery is disturbed. The chance of something being done wrong rises every time an item of plant is worked on. Nothing may go wrong the first time or the second time but with each additional disruption, there is an increasing possibility that an error will be made. Simple, fast, and uncomplicated access to individual items of plant and equipment means higher plant availability and a longer time between failures.

Vee-belt drives.

The article discusses the use of vee-belt drives. It covers some basic theories of friction drives and lists 11 factors to be considered when using vee-belt drives. A friction drive connects two shaft-mounted pulleys by a belt that is drawn taut enough to grip each shaft and turn them. The belt is pulled tight to create friction with the pulleys. As the drive pulley turns, the belt moves the connected driven pulley.

Chain drives.

Chain drives involve the use of a roller chain to turn a driven sprocket connected by the chain to a driving sprocket. They are used when precise speed ratios are required between the driver and driven shafts. A chain drive allows no slippage. An example is a gearbox driving a conveyor. Chain drives are also used when a large amount of power is required through the drive. For example the drive on large rotating kilns.

12 common electric motor repair causes.

This section presents a basic explanation of electric motor construction and operation along with twelve problems that can be encountered with their use. Most electric motors in industrial equipment are three-phase alternating current induction motors. Induction is the creation of an electric current across a gap. Two types of induction motors are commonly used: squirrel-cage and wound-rotor. The names come from the way they are built.

3-phase motor overload protection saves your plant.

A lot of equipment failure results from just simple, plain mistakes, sometimes from unintentional forgetfulness, sometimes from 'short-cut' taking, and sometimes because of ignorance of the consequences. The result is plants destroyed at great cost and inconvenience. But for a plant being driven by an electric motor use of under and over-current protection is something that can be done very cheaply to protect it from being run outside of its design 'envelope'. A current transformer is placed around the electrical cables leading to the motor. The transformer is connected to a monitoring device that alarms when the current is outside preset limits.

6 secrets of trouble-free lubrication success.

Grease and oil are the key lubricants used throughout the industry to reduce friction between metal parts. Lubricants can only reduce friction if their immediate environment sustains their lubricating properties. Once the operating conditions are known a suitable lubricant with the right properties can be used. When the lubricant is in place it is necessary to maintain the environment and the machine to the specified design standards and protect it from changes to the design conditions. There are six key factors to address for trouble-free life where grease or oil lubrication is used on machinery.

Gain valuable insight and understanding; get your copy of Electric Motor Maintenance and Repairs whitepaper today!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$12.50

An Excerpt From Electric Motor Maintenance and Repairs whitepaper

"PROBLEMS WITH ELECTRIC MOTORS"

Water Ingress Into the Electric Motor:

Water ingress into the motor will go between the stator coils or into the terminal box and short circuit and burn out the motor.

Water must never be allowed to get into a motor. If motors are to be used in wet areas they must be of the correct ingress

protection (IP) rating.

Electric Motor Overheating:

Overheating can occur from under-sizing the electric motor, insufficient cooling at low speed when using variable speed drives (VSD), and changes to the load on the motor such as jammed equipment and hot ambient conditions. Temperature detection (thermistor) and automatic shutdown devices can be installed. Attaching a separate booster fan to aid the motor fan solves the overheating problem when a VSD is used to control the motor speed.

Bearing Failure:

Bearing failure on motors can be an indication of the incorrect bearings for the application. A motor mounted vertically

needs different bearings than a motor mounted horizontally. A motor driving a large or multi-belt drive will require bearings that

handle big radial loads. A motor bolted to a distorted base plate will twist (See Soft Foot). Check bearing types with the

manufacturer.

Idle Electric Motors:

Electric motors in-store or not in operation for long periods of time get false brinelled bearings where the bottom bearings etch into

the shaft. Turn the motor shaft a quarter turn monthly. Bearings in motors in-store exposed to low vibrations through the

ground can cause brinelling too. Sit motors on a sheet of 3-mm rubber to insulate them from ground-born vibrations.

8 more common electric motor repair causes in the whitepaper.

Please contact us with any questions.