Industrial Dust Control Solutions

Industrial Dust Control Solutions and Dust Collectors

By Mike Sondalini

This Industrial Dust Control Solutions whitepaper provides the essentials, industrial dust control solutions, and details of common industrial dust collector systems. Required procedures are provided, like how to change dust collector bags in pulse jet dust collectors. As you will see below, Mike even covers the dust bearing, hopper bridge, cyclone separator design, and static electricity. It is 18 pages long.

Mike goes into detail on dust collection equipment, too. For example, in the section on pulse jet bag house dust collectors, he covers the twelve factors spanning their design and operation. In the section on combustible dust classification for hazardous areas, keep in mind that it is from a dust control Australia perspective, as Mike is an Australian BEng(Hons), MBA, and CPEng.

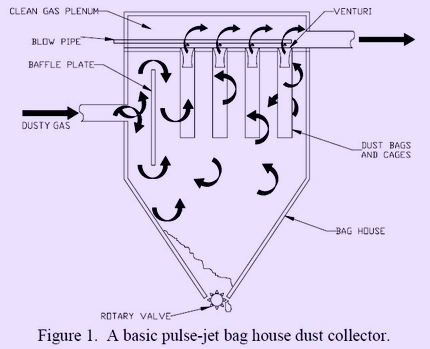

Dust continually builds up on the outside of the bags and a 'filter cake' develops. As the cake thickens, the gas flow falls, and less gas is filtered. The dust cake is cleaned off the bag to maintain the gas flow. The two common methods used to 'drop' the cake off the bags are to shock pulse the bag with an air blast or to shake the bag with a vibrating arm. Figure 1 shows the basic design of a pulse jet dust collector.

Industrial Dust Control Solutions & Dust Collectors PDF - Contents:

Dust control solutions and concepts.

Industrial dust results from material escaping from the confines of a process or a storage location. The size of the problem depends on the dust's characteristics and the means of its distribution. The best dust control solution for dust control is to keep it from where it ought to belong. Simple techniques can be used to manage dust and prevent it from becoming a significant health and environmental problem once the mechanism of creation and distribution are understood.

Jet dust collectors.

A bag house for jet dust collectors separates dust from a dust-contaminated gas stream. The gas is filtered through fabric bags. The fabric traps and filters out the dust while the cleaned gas passes through. The fabric consists of either woven or intertwined (felted) fibers. The bag fiber is selected for its ability to give a long working life within the dust collector's internal environment. In this section on pulse jet bag house dust collectors, we cover twelve factors spanning their design and operation.

Dust collector bag selection for bag houses.

The dust collector bags within a bag house must handle the process conditions they experience. The choice of bag materials is usually based on the cheapest fabric that will handle the conditions for a minimum of 3 to 5 years of operation. The selection of the dust collector bag materials requires a good understanding of the process temperature, moisture content, chemical reactions with the bag fiber, dust loading effects, and behavior of the dust bags in operation.

Changing out dust collector bags.

The dust bags in pulse jet dust collectors require replacement if they are damaged and leaking or if the product blinds them. This work procedure indicates the process and methods for changing out and replacing dust bags and cages in a dust collector.

Dust bearing - Protecting bearings from dust.

Protecting bearing from dust. Protection methods like labyrinth rings, rubber seals, felt seals, and shaft mechanical seals are described. Choosing the appropriate shaft seal and seal configurations to protect against dust ingress. Numerous shaft seal designs suited to dusty conditions are reviewed.

Bridging in silos and hoppers.

Bridging is the name given to the self-created arch that develops just above the outlet of a bulk material silo or hopper as it empties. A bridge forms when wall friction holds up the ends of the arch. To overcome bridging the wall, friction must be reduced or prevented from occurring.

Cyclone separator design - a low-cost particle removal.

A cyclone separator separates larger, heavy particles from smaller, lighter particles. It does that by using a spinning column of gas to force the larger, heavier particles out to the walls of the cyclone. By changing the ratio of its dimensions, they can be used to remove particles larger than a selected size.

Industrial static electricity basics.

Static electricity is the build-up of opposite polarity (positive and negative) electrical charges on two different substances in contact by moving one surface across the other. The spark can occur from static build-up, which results from the opposite charges neutralizing themselves when the electrical field between them becomes strong enough to overcome the gap resistance. Static can occur on both conducting (metal pipes) and non-conducting (rubber) materials. Examples of industrial static electricity are moving liquids, gases carrying particulate, conveyor and vee-belts, printing equipment, rubber and plastic items, dry cleaning, and moving road vehicles and airplanes.

Combustible dust classification for hazardous areas.

Many explosions in the processing, manufacturing, and bulk materials handling industries involve flammable gases, vapors, and combustible dusts or fibers. Such chemicals are known as hazardous materials. This section provides a basic overview of the design requirements and maintenance practices for electrical equipment in hazardous areas according to combustible dust classification.

Gain valuable insight and understanding; get your copy of Industrial Dust Control Solutions & Dust Collectors PDF today!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$12.50

An Excerpt From Industrial Dust Control Solutions & Dust Collectors PDF

"Dust bag selection for bag-houses"

The behavior of Dust Bags in Service:

Dust bags are cleaned either by pulsing air through the center of them or by mechanical shaking. The air pulse is the most severe of the two

methods but is also the most effective, cheapest, and easiest system to maintain. The process dust is not meant to get through the fibers of the bag. The bags are designed so that the dust builds up as layers on the outside. The built-up layers act as the filter medium, and the bag is the only supporting structure to carry the dust layer. If the dust gets deep into the fibers, the bag is destroyed as a filtering device.

Process Conditions Review:

The bag material must be selected to handle the process conditions within the bag house dust collector. The maximum and average temperatures must be measured, including how long the maximum temperature is sustained. As some fibers do not like damp conditions, the relative humidity level within the dust collector must be known. The level and type of acid or alkaline in the process gas must be checked. So, as highly oxidizing environments, some fibers do not like the amount of oxygen present in the gas stream. The process chemicals in the gas stream must be known to address all aspects of bag fiber degradation. Finally, the dust size range should be analyzed so that the correct fiber weave or felt size can be selected and the amount of needling can be selected.

Please contact us with any questions.