Process Plant Utilities PDF

Process Plant Utilities Whitepaper

By Mike Sondalini

This Process Plant Utilities PDF is applicable to utilities in manufacturing plants too. Common utilities between the two include electric power, hydraulic fluid, steam, water, fuel, sewer, refrigeration, etc. Mike offers in this whitepaper, insight into compressed air and other pressure-related utilities as well as some of the common ones. 31 pages.

He also covers in this whitepaper, additional insight into equipment common to many of the utilities above. Topics like Flange bolting-up practices, storage tanks, cooling tower design, boiler basics, and more. Even some less-discussed utilities like bitumen(asphalt) roadway repairs.

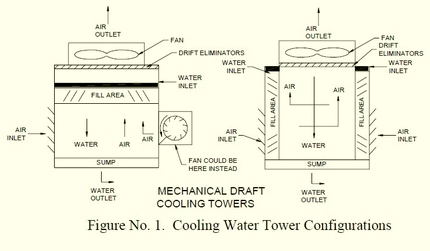

At the bottom of the tower is the sump where the cooled water collects. It is then drawn off by pumps and sent to the process. To reduce the loss of fine droplets blowing out of the tower (carry-over) another set of plates or fill is often used at the top of the tower as drift eliminators. Figure 1 shows two typical arrangements of mechanical draft for the cooling water towers.

Process Plant Utilities PDF - Contents:

Air compressor operation & care.

Doing a job safely is no accident! Like all good outcomes, safety is a result of good planning. To help recognize safety issues before they arise on a job Safety Analysis (JSA) may need to be performed. A JSA is a documented step-by-step safety action plan that lists the individual job tasks, the risks in each task, the consequences of the risk, and how each risk will be managed to ensure the safety of personnel. If you want safe work it needs to be planned as part of the job.

Plant compressed air waste reduction.

Every compressed air system will eventually develop leaks from connectors and redundant pipelines. Compressed air is very expensive to make. It is necessary to institute regular inspections for air leaks and fix them immediately.

Pressure equipment inspections.

Pressure vessels must be regularly inspected and maintained in safe operating conditions. New laws stipulate that all pressure vessels must have a Hazard Level rating that reflects the vessel's safety risk. The higher the risk the more stringent the requirements for operating and inspecting the vessel.

Locating pressure relief valves.

A pressure relief valve (PRV) is used to prevent overpressure in a vessel or pipeline. It consists of a disk pushed onto a seat by a spring. The seat is forced open with the rising pressure and relieves the build-up. The contact faces of the seat and disk are machined smoothly and accurately so no leakage occurs when the process pressure is less than the set pressure. The set pressure is the pressure at which the valve opens. If the pressure rises above the set pressure the force on the disk pushes the spring up and the valve vents.

Cooling tower design, operation and use.

There are two types of cooling water towers: natural draft and mechanical draft. A cooling water tower is used to remove heat from incoming hot water and reduce it to a lower temperature. It does that by evaporating off some of the hot water. The evaporated water takes away the heat. Exactly the same process occurs when your body sweets to keep you cool. You cool off even faster if there is a breeze blowing.

Membrane and leaf filtration overview.

One method to clean particles from a liquid or gas is to pass them through a filter. The filter is a screen that traps and holds the contaminants on its surface while allowing the fluid to twist its way past the build-up and screen. The screen can be used until the back pressure from the collected contaminants choke it so severely that the fluid flow falls drastically. At that point, the screen must be cleaned. This section explains how membrane and leaf filtration processes work and the critical factors that produce successful filtration results.

Steam trap operation and selection.

This section covers the operation of steam traps and how they work. Their duty is to remove condensate from steam piping to ensure only vapor is sent through the pipeline. Steam is a greatly used medium in the industry. Its use ranges from heating processes and domestic fluids to driving turbines by the expansion of the vapor. Yet the steam trap at the bottom of a drop leg is easily forgotten.

Flange bolting-up practices.

Bolts and gaskets behave like springs and unless flange bolts and nuts are properly tensioned the flange will leak. The correct tightening torque depends on bolt diameter, material of construction, process pressure and bolt fabrication.

Sealing threaded connections properly.

Threaded connections on process chemicals and utility piping can be difficult to seal. Leaks from threaded joints in steam and compressed air lines are common. The section examines how pipe threads are designed and work and what to consider in achieving proper sealing of treads.

Holiday detection in above-ground tank bottom lining inspection.

An important evaluation of bottom linings after application to aboveground storage tanks (AST) is holiday (i.e., discontinuity, pinholes) detection. Linings are principally applied to AST's to prevent internal corrosion that may be severe. Therefore, any holidays must be detected and repaired prior to the newly lined tank being returned to service.

Vertical bulk liquid steel storage tanks.

Bulk liquid storage tanks are constructed to contain large volumes of content. The nature of the content and the amount involved can impose major hazards and risks. For this reason, bulk liquid storage tanks must be constructed and maintained to high standards. The section reviews the requirements for building and maintaining vertical, bulk liquid storage tanks. Issues, which affect the care of large storage tanks as well as common problems, are reviewed.

Is your wet scrubbing tower working?

A wet scrubbing tower is used to clean odors, particles, mists, and vapors from a gas stream. The gas is forced through the tower. As it moves from the inlet to the outlet it is washed and cleaned. The washing is done with suitable chemicals that remove the active components in the gas flow. The gas is cleaned to environmentally acceptable levels and discharged into the atmosphere.

Fired packaged boiler basics.

Steam boilers not used for power generation and of smaller size and energy output are termed packaged boilers. The heat source is usually either electric coils or burning fuel. When a flame is used to heat the water it is known as a fired packaged boiler. Fired boilers are considered efficient steam generators with about 85% of the available energy converted to steam. They can be of water-tube or fire-tube design. Boilers incorporate many key aspects of heat transfer to create steam from water. This section describes how fired boilers work and their key components.

Bitumen roadway repairs.

Tarmac surface repairs are a common daily occurrence. To get long life from a bitumen repair there are several issues to consider. This section reviews the major considerations.

Gain valuable insight and understanding; get your copy of Process Plant Utilities PDF today!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$12.50

An Excerpt From Process Plant Utilities PDF

"INSTIGATE GOOD STANDARDS"

Using good engineering, installation, and maintenance standards and practices can prevent a lot of air leaks. Critical air supply systems should be fully welded. Important connections and pipes to equipment should be of stainless steel tubing and ferrule cone connectors or pressure-on-face sealing connectors. Mixing fittings and materials must be prevented. All connections should be in a position that can be easily reached for inspection and repair.

Train installers in the proper methods of sealing threads. Review old engineering piping standards and update them with better practices and then reissue them to the engineers and maintenance people. Explain the changes and train people in their use.

Please contact us with any questions.