Pumping Basics

Pumping Basics PDF Download

By Mike Sondalini

Before you tackle that pump project or repair, download Mike Sondalini's white paper "Pumping Basics" (Revision III). Mike pumps his years of experience into this white paper offering advice from mechanical seals to fluid dynamics. Well, the white paper does cover a little more than just basics with formulas, pressure, cavitations, pipe size, NPSH, and more. 30 pages

Mike reflects on real-life experiences with the centrifugal pump, sharing knowledge you can apply to your horizontal centrifugal pump and vertical centrifugal pump. Pumping basics also cover issues to consider when moving a slurry pump. Learn about pumping basics before you tackle that submersible water pump.

A must-read for facilities maintenance, and engineering.

Pumping Basics white paper - Contents:

Changing the service duty of a pump

When centrifugal pumps are modified to perform a different duty the new service head, flow, and motor power characteristics are calculated from the Similarity Laws.

Shaft sealing with a packed gland

This section discusses the use of compressed, stacked packing for shaft sealing. Topics covered include an explanation of how packing works, what to consider when using packing, good installation practices, and commissioning shaft packing.

Get mechanical seals working properly

Mechanical seals are used to keep the bulk contents of rotating equipment such as pumps and compressors from escaping. They do this by sealing the shaft that protrudes from the casing. They require quality installation and operation conditions for long life.

Effects of centrifugal pumps on right end of pump curve

Pumps are designed and selected to operate near their highest efficiency point. If they operate at the right-hand end of the pump curve the likelihood of cavitation increases.

Net positive suction head losses

Pumps cavitate and run dry when the pressure leading into them falls below the vapor pressure of what they are pumping. At the vapor pressure, the liquid boils into a vapor and the liquid never reaches the pump. In order to know that the pressure to a pump is always above the vapor pressure, it is necessary to calculate that the pressure losses from pipe friction and suction lift will not cause the pressure to drop under the vapor pressure. The presence of dissolved gas in the liquid complicates the problem.

Sizing pipelines easily

Designing pipe work for liquid flow requires calculating the pressure losses along the pipe due to pipe friction. Once the losses are known the right pipe diameter can be selected. If full engineering calculations are not possible the conservative approach is to select pipe sizes that produce a velocity of less than 3 m/sec.

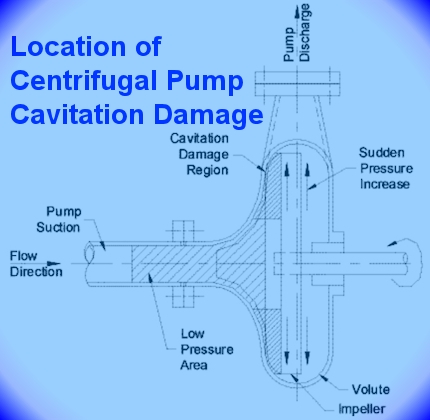

Centrifugal pump cavitation

Cavitation in pumps is the presence of collapsing gas bubbles in a liquid stream. Under very low-pressure conditions the liquid vaporizes and boils. The gas bubbles collapse when they enter a region of high pressure. It is often heard as a rumbling sound coming from the pump. The collapsing bubbles cause mini-implosions that tear metal out from impellers and volutes.

How fluid flows in pipes

This section explains what happens to fluids flowing through pipes. A fluid is either a liquid or a gas. In industry they are piped from storage to the point of use. Correct design and installation of the piping system minimizes pressure loss and improves the behavior of equipment and processes.

Static electricity basics

Static electricity is the build-up of opposite polarity (positive and negative) electrical charges on two different substances in contact by the movement of one surface across the other. The spark that can occur from static build-up is the result of the opposite charges neutralizing themselves when the electrical field between them becomes strong enough to overcome the gap resistance. Static can occur on both conducting (such as metal pipes) and non-conducting (such as rubber) materials. Examples are moving liquids, gases carrying particulate, conveyor and vee-belts, printing equipment, rubber and plastic items, during dry cleaning, on moving road vehicles, and airplanes.

Moving slurries about

The slurry is solid particles in a liquid. Concentration can vary from mostly liquid to mostly solid. Slurries are usually transported through pipe work using pumps, pressurized gas, or steam. Different concentrations and different particulate produce different flow characteristics. Successful slurry transport requires knowledge of the particulate, its transport behavior in the liquid at different concentrations and speeds, the nature and friction effects of the pipe work system, and selection of the right motive method for the application. This section provides information for transporting slurries of up to 60% solids concentration.

Don't wait until your facilities are under pressure, get a copy of Pumping Basics now!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$15.00

An Excerpt From Pumping Basics white paper

"VISCOSITY AND DENSITY EFFECTS"

Liquids do not all behave the same. Blood has different flow characteristics than water. Paint flows differently than gasoline petrol. Liquids are categorized by their behaviors when undergoing shear. Those liquids that have a constant shear rate with the change of velocity (like water) are called Newtonian ( Newton first developed the mathematical explanation for the phenomenon). Those with shear rates that vary with changing velocity (like paint and blood) are Non-Newtonian. The shear rate is a measure of a fluid's viscosity or slipperiness.

The density of a fluid affects its viscosity. Fluids with more mass per unit volume are heavier and require more energy to move them and shear less easily. A temperature rise decreases the viscosity and density of liquids. The more viscous, or less slippery, a fluid the harder it is to get shearing between layers. The high viscosity prevents rapid velocity changes from occurring between layers. The sub layer in viscous fluids is thicker than in low viscosity fluids.

Sample from Pumping Basics: Mechanical Seal Repair

Need more information on pumps? Download the Complete Pumping white paper Set!

Please contact us with any questions.