Compressor Operation and Maintenance Training Assessment Assessment

Compressor Operation and Maintenance Training Assessment :

This assessment is to evaluate your Working Knowledge of Compressor Operation and Maintenance. AKA the plant bottleneck.

Please consider our training while here ...

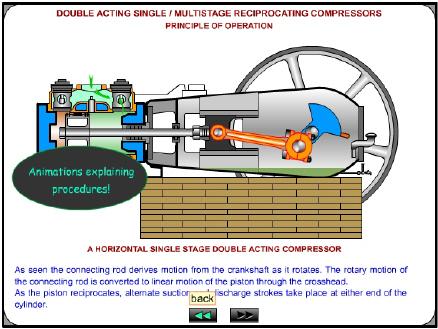

To learn more about compressors, see our Air Compressor Training Course. Detailed coverage on reciprocating, centrifugal & screw compressors.

Compressor Operation and Maintenance Training Assessment test details:

( 8 Questions )

This assessment is to evaluate your Working Knowledge of Compressor Operation and Maintenance. AKA the plant bottleneck.

Published: