PID Tuning Blueprint Kit (Professional)

- Home >

- vocational-training >

- plc-training >

- programming >

- pid tuning calculator tips

Simplifies tuning PID loops and provides many PID tuning tips.

By Finn Peacock

Please click each of the 6 items above to see sample.

| PID Tuning Blueprint eBooks and Software Download | |

| ESBN: F06-295J-9P78-54B9 | |

Description: Over 88 pages with PID Calculator and PID Simulator

The PID Tuning Blueprint Kit Pro contains the most simple PID tuning methods ever devised, plus many PID tuning tips, PID Calculator, and PID simulator. Download Step by step instructions, the logbook, cheat sheet, the Idiot's Guide to Algorithms, and simulation software with calculator designed into MS Excel. Save downtime cost and it is great for training. Discount licenses for Schools, Corporations, and Government multi-user Kits.

Control Engineering magazine tested 5 vendors' autotunes in their January 2009 issue. 80% didn't work at all. So even if your controller has the auto-tune feature, you will need this PID Tuning Blueprint. The PID Tuning Blueprint is proven to tune most Temperature Controls, Flow Controls, Pressure Controls, Level Controls, pH Controls, Speed Controls, and Servo Controls.

The PID Tuning Blueprint walks you through a step-by-step check of all the process fundamentals before the tuning begins. PID tuning tips learned from over a decade in the game, that you won't find in any textbooks. Unlike other PID Tuning products, you won't need a Ph.D. in math to understand this material.

Combining the PID Tuning methods detailed with the PID Tuning Calculator results in ...

Finn Peacock has used the same PID Tuning methods assembled from lots of different sources over his 12 years as a control engineer working with some of the best Control Engineers in the world. He used these very same techniques to tune PID loops from nuclear power plants to chocolate factories. The PID Tuning Blueprint takes you by the hand and guides you through the process of identifying how YOUR controller works and what units it uses. You then get all the tools you need to translate your freshly calculated tuning constants into your controller's language.

Customer Comments ... "Easy to use and to follow. This is probably is the best down-to-earth material for tuning PIDs that I have ever seen. Really,.. it is Idiot Proof. It is like you just follow the lines painted on the floor and you will arrive safely at your destination. Using your Blueprint, my process was tuned with just PI. PID was not necessary after it was so well-tuned." Francisco Lopez - Advanced Integrated Solutions Inc - USA

"What I liked most about the PID Tuning Blueprint was its simple approach. We have implemented it on our clients' processes and the results are great." Stefano Ruede - Engineering Solutions Inc - Oregon, USA

"In implementing the PID Tuning Blueprint, I was able to uncover instability in the glycol cooling loop. The company was impressed by how the PID Tuning Blueprint was able to be used as such an effective tool in identifying deficiencies in the glycol control loop, at a fraction of the cost of software such as RSTune." Terry King - Gay Lea Foods - Ontario, Canada

"I like the fact it is plain English with humor interjected." David Molley - Industrial Innovations Inc - Los Angeles, USA

|

An email with a download link sent immediately after purchase.

PID Tuning Blueprint Contents ...

PID Tuning Blueprint: Guidebook

- You'll get this step-by-step guide explaining the unique PID Tuning technique, and how to apply it to your specific process. It's 65 pages filled with only what you need to know, so it shouldn't take you more than an hour to work your way through. You can begin implementing the steps immediately. sample

PID Tuning Cheat Sheet

- Once you've used the Blueprint to tune your first loop, you can progress to using this 2 sided cheat-sheet to quickly tune subsequent loops. The cheat sheet is a super-condensed guide to the tuning process that you can easily refer to out on the plant, to ensure that your loops get tuned as efficiently as possible.

PID Tuning Logbook

- You will be asked how you got that process working so sweetly. And if you fill in the blanks in a fresh copy of this logbook as you tune each loop, you will have a record that will show exactly what you did to improve the process -- and crucially how much you improved it by. (Always useful when negotiating your next pay raise!) sample

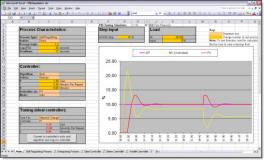

PID Tuning Simulator and PID Tuning Calculator for MS Excel

The best PID tuners in the business are those who try out their newly calculated tuning parameters on a 'fit for purpose' simulation before investing in both the effort and downtime required to implement them on their physical process. This sophisticated spreadsheet actually simulates your process and controller right inside the familiar environment of MS Excel. Here's how it fits into your PID loop tuning process: sample

a)You follow steps 1-7 as per the Blueprint (despite what some software vendors may claim - these essential steps cannot be automated).

b)You go through each configurable cell on the main worksheet and dial in your process, controller, and desired performance characteristics.

c)The algorithms in the spreadsheet automatically calculate your optimum tuning constants (using the exact same rules as described in the Blueprint). The spreadsheet also automates the process of converting the raw tuning constants to values that your specific controller type can use.

d)The simulator shows you how your simulated process will respond to those tuning parameters based on setpoint and/or load changes.

e)You spot any mistakes in your tuning well before you touch your plant, and gain confidence in the tuning technique that you have just learned.

This is also a great learning tool for playing with the controller setup and seeing how the different parameters affect the process performance. This is written in Excel so that you have complete access to all the algorithms that drive the simulation and the tuning. If you want to understand exactly why something is happening in the simulation or the calculator - simply unprotect the sheet (no password required) and the workings are there for you to see.

The Complete Idiot's Guide to the PID Algorithms

This guide to the PID algorithm and the mathematical concepts that underpin it - is written so that anyone can get an intuitive understanding of how the algorithm works and why. This crash course uses the analogy of a car on a freeway changing lanes to represent the process under control and walks you through easy to visualize "thought experiments" to cement the concepts in your mind. If Integrals, Differentials, and the inner working of the PID algorithm are a mystery to you - this "Idiot's Guide" will give you the A-HA! The moment as everything finally makes sense. sample

Automated Process Linearizer for MS Excel

A critical step of any tuning process is to ensure that your process responds linearly to your controller output (See the Blueprint Guidebook Section 8). This Macro automates the linearizing process. You simply paste your process data in - and the macro works out a lookup table that you can use in your controller to hugely improve the performance of your loop. sample

An email with a download link sent immediately after purchase.

Related Products: