Centrifugal Pump Training & Troubleshooting Guide

- Home >

- vocational-training >

- mechanical >

- centrifugal pump course

Centrifugal Pump Training Certificate Course

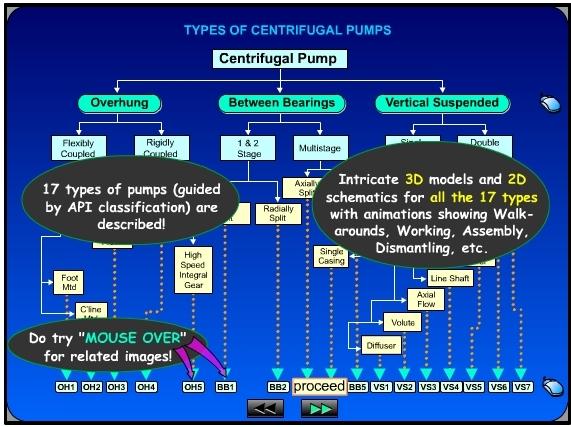

This course covers centrifugal pump types and related components, plus a pump assembly simulator and skill test.

Tap the above picture for the centrifugal pump demo video.

Centrifugal Pump Training and Troubleshooting Guide

ESBN: DD6-1243-6040-FH25

Description: (40 hrs)

This Centrifugal Pump Training and Troubleshooting Guide covers many pump types. It also provides detailed pump classifications. The focus on centrifugal pump graphics/animations helps us understand their maintenance. It also helps to learn its operating principles. Principles like pump cavitation, performance curves, NPSH, suction head, discharge head, and priming. This knowledge aids in pump repair.

The course provides detailed knowledge of pump assembly and dismantling. The Centrifugal Pump Training Guide has a module for pump troubleshooting. Animated cutouts offer deep insight into how centrifugal pumps work.

- Basics & Principles of Centrifugal Pump - Working

- Detailed Understanding of API - 610 types of pumps

- Extensive 2D / 3D Graphics, Models and Animations, Highly Interactive

- Supported Troubleshooting Guide Glossary,

- Games on Component Assembly, Skills Tests, and Certificate Printouts

Who Can Benefit:

Students and maintenance and engineering personnel will find that this general centrifugal pump guide increases their knowledge. It will boost confidence in working with most pumps and their parts. Those with previous training may find this tutorial a good refresher. They may learn some important information not covered in their original training.

Hardware Lock:

This course is also available using a "Hardware Lock" licensing method. Many users want to use the software on multiple computers. For example, they want to work with it on both their office and home computers. This Hardware Lock method allows users to install the software on as many computers as they like. They only need to enter the key on whichever computer they want to use the software. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

You can also ask us to embed your company logo in the training software for the hardware lock option.(Please note the URL of your company logo in the comments when ordering, or email your logo to us to use this feature.)

We will send an email confirming the order within 24 hours after purchase. If you ordered a downloadable version, check your email. It has the download link and activation code. We send a second email with tracking info if you ordered one of the shippable versions.

Download (1 Installation on 1 PC, Unlimited users, 1 User at a time.) $149

1 Hardware Lock (Unlimited Installations, Unlimited number of PCs, 1 User at a time.) $349

1 Network Hardware Lock (Network Installation, Unlimited number of PCs, 10 Users at a time.) $1049

1 Network Site License (Network Installation, Unlimited Simultaneous PCs and Users) $2100

Schools or companies needing a SCORM version of the above site license, please contact us and request a quote.

Pump Course Table of Contents

1. Introduction

2. Pump Classification

- 2.4. Type and Construction based on:

- 2.4.1. Suction Design

- 2.4.1.1. Single

- 2.4.1.2. Double

2.4.2.1. Single

2.4.2.2. Multistage

2.4.3. Guide Vanes

2.4.3.1. Volute

2.4.3.2. Turbine

2.4.4. Casing Construction

2.4.4.1. Radially Split

2.4.4.2. Axially Split

2.4.4.3. Double Casing

2.4.5. Impeller Shrouds

2.4.5.1. Open

2.4.5.2. Partially Open

2.4.5.3. Closed

2.4.6. Shaft Position

2.4.6.1. Horizontal

2.4.6.2. Vertical

3. Centrifugal Pump Basics

3.1. Principle of Operation

3.2. Pressure Concepts

3.3. Hydraulics - A Few Basics

3.4. Vapor Pressure

3.5. Pump Cavitation

3.6. Pump NPSH - Net Positive Suction Head

3.7. Pump curves / Pump Performance Curves / Pump Characteristic Curves

4. API 610 Types and features

4.1. Overhung

4.1.1. Flexibly Coupled

4.1.1.1. Horizontal

4.1.1.1.1. Foot Mounted : OH1

4.1.1.1.2. Center Line Mounted : OH2

4.1.1.2. Vertical

4.1.1.2.1. In-line Bearing Frame : OH3

4.1.2. Rigidly Coupled

4.1.2.1. Vertical

4.1.2.1.1. In-line : OH4

4.1.2.2. High Speed Integral Gear : OH5

4.2. Between Bearing

4.2.1. 1st and 2nd Stage

4.2.1.1. Axially Split : BB1

4.2.1.2. Radially Split : BB2

4.2.2. Multistage

4.2.2.1. Axially Split : BB3

4.2.2.2. Radially Split

4.2.2.2.1. Single Casing : BB4

4.2.2.2.2. Double Casing : BB5

4.3. Vertical Suspended

4.3.1. Single Casing

4.3.1.1. Discharge Through Column

4.3.1.1.1. Diffuser : VS1

4.3.1.1.2. Volute : VS2

4.3.1.1.3. Axial Flow : VS3

4.3.1.2. Separate Discharge (Sump)

4.3.1.2.1. Line Shaft : VS4

4.3.1.2.2. Cantilever : VS5

4.3.2. Double Casing

4.3.2.1. Diffuser : VS6

4.3.2.2. Volute : VS7

4.4. Wear Ring Running Clearances

4.5. Mechanical Seal Types / Arrangement / Plans

4.6. Cooling Water Piping

4.7. Lube Oil System

5. Conventional and Interactive Skill Tests with evaluation

6. Games & Component assembly

6.1. Overhung Pump - OH

6.2. Between Bearing Pump - BB

6.3. Vertical Suspended Pump - VS

7. Technical Glossary

8. Troubleshooting Guide

Failure or deviation symptoms

o Pump does not deliver

o Insufficient capacity delivered

o Insufficient discharge pressure developed

o Pump loses prime after starting

o Pump requires excessive power

o Stuffing box / mechanical seal leak excessively

o Packing / mechanical seal has short life

o Pump vibrates or noisy

o Bearing have short life

o Pump overheats and seizes

Around 45 specific root-causes have been identified similar to the few listed below:

o Pump not primed

o Suction lift too high

o Insufficient margin between suction pressure and vapor pressure

o Total head required by process lower than pump design

o Specific gravity of liquid different from design

o Operation at very low capacity

o Parallel operation of pumps unsuitable for such operation

o Misalignment

o Bearings worn out

o Wearing rings worn out

o Rotor out of balance causing vibration

o Improper selection, fitting or usage of mechanical seal

o Lack of lubrication

Related Products:

Infrared Inspection of Mechanical Systems

Gas and Air Compressor Training CD/USB

Hydraulics Training Certificate Course

Industrial Hydraulic Systems and Circuits

Hazardous Area Instrumentation Training

Please contact BIN95 with your questions and comments.