Industrial Electrical Training Video Library

(Electrical Control Circuits, Motor Controls, and PLCs)

10 Industrial electrical training videos, handbook, instructor's guide, exams, and course completion certificate.

An industrial electrical training video course, ten units in Download, CD or DVD format about electrical control with video reference handbook, instructor's guide, answer key, a master set of exams, and course completion certificate. The most critical and fundamental skills your maintenance department needs are Electrical Power Distribution, Electrical Components and sensors, Electrical Diagrams (Schematics), PM, Troubleshooting, Electrical Motor Controls, and PLC Technology. Includes DC and AC motor controllers, 3-phase transformers, and many more industrial motor, power, and automation control training modules.

Great for training maintenance and industrial engineers.

Industrial Electrical Training Video Course Library

In Interactive CD/Download (software) or DVD Formats

10 Industrial Electrical Training Video Course Library (Over 10 hours of video, 30 course hours est.)

Prod #: I01-700E-9U12-98G4

Industrial Electrical Training Course Content:

- Understanding 3-Phase Power and Plant Distribution

- Electrical Switching, Timing & Control Devices

- Instrumentation: Discrete & Sensory

- Understanding Electrical Diagrams & Control Circuits

- Preventive Maintenance & Troubleshooting Control Circuits

- Introduction to Electrical Motor Control Operations & Protection

- Sizing the Protection of Electric Motors & Control Circuits

- AC Motor Controls & Troubleshooting

- DC Motor Controls & Troubleshooting

- Understanding & Applying PLCs in Electrical Controls

We show how these devices work, how they are wired, and how to troubleshoot them.

Get everyone up to speed on electrical maintenance troubleshooting. This program also provides the first step in learning electrical diagrams, which is excellent for beginners and cross-training mechanics. The complete series provides approximately 30 hours of instructional material, and the topics covered are equivalent to a multi-week course.

In addition to enforcing and maintaining the National Electric Code (NEC), our programs also help complement and support the employee training requirements of OSHA 29 CFR 1090.332 and ISO 9000 Section 4.18 regulations.

The Industrial Electrical Training Series Includes:

The first electrical training video gives your employees a solid understanding of power generation and distribution basics. Cut your power bills and extend the life of your equipment. The following two electrical training videos cover the most common switches, timers, and control devices found in plants, followed by two more DVDs covering electrical diagrams. The next four electrical training video DVDs cover motor control extensively, including both DC and AC motor control protections, maintenance, and troubleshooting. The last DVD in this library covers understanding & applying PLCs in electrical controls.

The Electrical Training Instructor's Guide and Answer Key are also provided if requested. The DVD version of this course includes 1 hardcopy of workbooks and a test for each of the 10 modules [a Student Kit] for individuals ordering this course. If you would like to order additional hard copies for each employee/student, the cost will be an additional $320 per employee/student Kit (a set of 10 workbooks, one for each training module).

Download the Industrial Electrical Training Brochure PDF.

New Interactive CD/Download [Software] format:

When ordering below, you will see that the new Electrical Training Interactive CD or Download format option has been added to the standard DVD/printed workbook delivery format.

In choosing the interactive CD or Download format, you will not need printed workbooks as they are built into the interactive CD/Downloads in the form of Review Questions, Final Tests, and printed certificates with the students' scores. Use CD/Download for a single student or unlimited user in your facility.

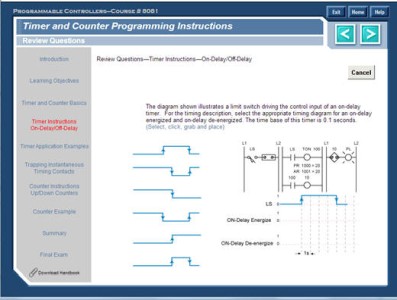

Review Questions

Use our exclusive interactive software to train and evaluate everyone using the CD/Download program. Just watch one of the lessons. Then, they can take a review quiz to see how much was learned. For each question, the learner gets instant feedback, and if they miss a question, they receive a follow-up question to make sure they understand the explanation provided in the feedback.

Final Exam

Assess the performance of each person going through the programs. An interactive Final Exam consists of 20 randomly selected questions from a pool of questions.

See the easy comparison chart to decide which training format best suits your needs. ![]()

The software never expires, and there are no annual fees!

FREE Shipping: Within 24 hours, a second email with shipping info will be sent. You must include the shipping address when ordering or email it to us to avoid delays. All orders are shipped USPS Priority or Express mail, and no PO boxes are allowed, as the Industrial Electrical Training Video Series and handbook can be larger than the mailbox.

Note: The international importer is responsible for all customs duties (taxes).

For training cost justification for this video course library, please tap TRAINING COST JUSTIFICATION HELP

If you click on each of the Industrial Electrical Training Download/CD/DVD titles below, you can watch a sample video from each training video. Please note that because of the streaming, the quality is not as good as the actual Download/CD/DVDs.

Electrical Training Video Library Curriculum:

Section 1

This section covers the Electrical Power Distribution:

- Cut your power bills and extend the life of your equipment by using power factor correction.

- Choose the safest methods for power distribution.

- Configure wye and delta branch and feeder circuits to provide a balanced power system.

- Learn which voltage connection to avoid to prevent equipment damage.

- Determine phase-to-phase and phase-to-neutral voltages and currents.

- Distribute power through your plant via switchgear and busways.

- Rectify AC power into DC power.

- Make sure you place correction capacitors in the right place, or else your motor overload heaters won't work right, and you'll burn out your motors.

- Provide a safe ground bus for safety and proper equipment operation.

Includes one Download/CD/DVD for this section. See the link below for more details and a demo ...

Understanding 3-Phase Power and Plant Distribution (51:16 min)

Section 2

This section covers Electrical Components & Sensors:

- Avoid costly electrical wiring mistakes; read multi-position selector switches in electrical diagrams.

- Troubleshoot tricky pushbutton problems, don't replace the whole thing when it might just be the contact blocks.

- Use time-delayed and instantaneous timer contacts, know the difference, and protect your equipment.

- Troubleshooting relays can be a nightmare, follow our detailed electrical troubleshooting method and save time.

- Many control devices share components, learn how to cut your spare parts inventory to a minimum.

- Choose the correct photoelectric sensor for your application.

- Apply, install, and troubleshoot limit, photoelectric, and proximity switches.

- Should you use an inductive or capacitive prox, they look the same, but if you pick the wrong one, it won't detect properly.

- Wire and understand the inner workings of 2, 3, and 4-way valves.

- Cut your installation time, bench test, and calibrate pressure devices before installation.

- Clogged ports or a bad solenoid, learn to spot the difference and avoid replacing unnecessary components.

- Intermittent malfunctions in limit switches can take forever to track down, learn a step-by-step method for identifying and solving the electrical problem quickly.

Includes two Downloads/CDs/DVDs for this section. See the links below for more details and a demo ...

Electrical Switching, Timing & Control Devices (60:14 min)

Instrumentation: Discrete & Sensory (50:22 min)

Section 3

This section covers Electrical Diagrams (Schematics), PM, and Troubleshooting:

- Learn to design and read layout, Wiring, and Electrical Diagrams.

- Protect your people, and follow our four basic rules of Electrical diagrams to implement a safe circuit.

- Add interlocking, memory, and cross-referencing to complex control circuits.

- Layout a control panel from scratch to finish by following the wiring and layout diagrams.

- Implement motor control and magnetic starter circuit diagrams.

- Prevent faulty operation and equipment damage by using mechanical, push buttons, and electrical interlocks.

- Follow our systematic approach to troubleshooting electrical systems both at the power source and the control circuit.

- Find short circuits and faulty components quickly and get back up and running fast.

- Install power and phase monitors to detect dangerous conditions before causing costly motor damage.

- Use our four fundamental guidelines to implement an effective preventive maintenance program.

- Perform dynamic and static preventive maintenance inspections.

- Troubleshoot control circuit logic using the ladder and wiring diagrams.

- Learn how a phase imbalance will make your motors run hot, solve the problem, and prevent insulation breakdown.

- Learn why thermal overloads aren't enough to protect your equipment against damage from phase loss.

Includes two Downloads/CDs/DVDs for this section. See the links below for more details and a demo ...

Understanding Electrical Diagrams & Control Circuits (52:12 min)

Preventive Maintenance & Troubleshooting Control Circuits (34:53min)

Section 4

This section covers Electrical Motor Controls:

- Learn to prevent the seven most common causes of heat-related motor failure contactors and starters for your application.

- Class 10, 20, and 30 heaters, which class offer the proper protection for your motor application.

- Implement proper arc suppression to protect against shorts and ark hazards.

- Make sense of NEMA standards.

- Learn how spending a few extra dollars can add invaluable backup motor protection.

- Use our six-step method to implement and maintain a safe motor branch circuit.

- Time-delay or non-time-delay fuses, which one should you use to provide the best protection.

- When it comes to motor nameplates, reading them isn't enough, everyone needs to understand what they mean and know how to use this valuable information.

- The motor dictates circuit design, protection, and components, know how to get the requirements from Article 430 and make your job easier.

- Select the correct size fuse to protect a branch circuit, we'll show you how.

- Choose the right NEMA starter for your motor.

- A clear explanation of Article 430 and what it means to your motor control operations.

- Troubleshoot solid-state starters by quickly detecting the misfiring of SCRs.

- Troubleshoot across-the-line start motors and the five types of reduced-voltage start motors.

- Understand how variable speed drives work and where to look to solve problems.

- Quickly troubleshoot multispeed motors and their circuits and learn how to double-check the connections.

- Keep the production line running and learn to troubleshoot and control the speed of DC motors.

- Avoid the most common mistakes made during the installation and maintenance of brushes.

- Learn how to detect an SCR fault in the power bridge of a DC drive.

- See how noise can affect the operation of a DC drive and learn to correct it.

- Understand how DC motors are reversed so you'll be better prepared to troubleshoot them.

- Use our proven techniques to detect problems in a series, shunt, and compound DC motor before they break.

Includes two Downloads/CDs/DVDs for this section. See the links below for more details and a demo ...

Introduction to Electrical Motor Control Operations & Protection (64:32 min)

Sizing the Protection of Electric Motors & Control Circuits (22:02 min)

AC Motor Controls & Troubleshooting (64:11 min)

DC Motor Controls & Troubleshooting (38:13 min)

Section 4

This section covers PLC Technology:

- If you're using PLCs to control motors, make sure you're implementing low-voltage protection, we'll show you how and help you avoid potential injury to personnel and equipment.

- Is your PLC system safe and properly installed, learn which sections of the control circuit must be left hardwired for safety reasons.

- One small wiring mistake during troubleshooting will make things worse, we'll show you how to do it right.

- Follow our step-by-step method of converting a hardwired relay system to a PLC-based system, do it quickly and do it right!

- Troubleshoot the complete discrete I/O system, and see it graphically, from power line problems to wiring connections to I/O modules to the detection of a bad field device.

- Does everybody on your staff know how to troubleshoot PLCs and I/O, learn how to use the power of the PLC and its monitoring capabilities to help you.

Includes two Downloads/CDs/DVDs for this section. See the links below for more details and a demo ...

Understanding & Applying PLCs in Electrical Controls (64:53 min)

Customer Comments:

"A very complete system. It's exactly what I expected!"

- Dale Frazier, Electronic System Technician, City of Columbus, OH

“After viewing the program, we believe that your PLC Video Training Series is the best on the market and definitely meets our needs.”

- George Cooros, Training Instructor US Steel Corp.

"I like the straightforward way the books are written."

- Joseph Lustig, Airco Special Gases

"I really like your training programs. My staff basically grabs a tape and trains themselves."

- Dale Lancaster, Maintenance Manager, Color Box, Inc.

"You've made my job much easier, helped our electrical department, and lowered the overall machine downtime in our facilities."

- Nick Meheula, Plant Maintenance, Oahu Transit Services

"Your programs have not only given my staff a better understanding of electrical controls but also reduced our troubleshooting time. I would recommend them to other companies."

- Rodney Nylin, Technical Training Coordinator, Abbott Laboratories

"The information in these training programs is accurate, to the point, easy to understand."

- Jerry Roshong, Project Engineer, J, M. Smucker Company

"Your video programs are convenient to schedule. We can train all three of our shifts in a very convenient and economical way."

- Rick Pruden, Electrical Engineer, Bundy Corporation

"These troubleshooting programs are essential not only to electricians but also to our mechanics."

- Joe Meccia, Production Maintenance, Current, Inc.

"I have passed your info on to other companies and friends. I was happy to find these videos, it's hard to find good quality products."

- Ed Godin, VP Manufacturing, Falcon Plastics, Inc.

"I've had the opportunity to evaluate many training materials and I've found these video training programs to be the best I've seen."

—Bob Desoto, Continuing Education Professor, University of California-Fullerton

"You covered a huge amount of detail well. It was very easy to understand."

- Jeff Camp, Senior System Engineer, United Control

"We looked at video training from several different companies. We like this training video program so much we bought it immediately. They cover everything that we really need to know."

- George Cooros, PLC Training Instructor, US Steel Co.

FREE Shipping: Within 24 hours, a second email with shipping info will be sent. You must include the shipping address when ordering or email it to us to avoid delays. All orders are shipped USPS Priority or Express mail, and no PO boxes are allowed, as the Industrial Electrical Training Video Series and handbook can be larger than the mailbox.

Note: The international importer is responsible for all customs duties (taxes).

Learning Path:

We recommend:

1st Industrial Electrical Training Video Course 10DVD (page you are on now)

2nd Electrical Motor and Controls Course

3nd PLC Basics

4rd HMI Basics

5th PAC - Controllogix and RSLogix 5000

6th PLC Training scholastic Video Course 10DVD

7th Online PLC Structured Text Programming Basics Course

8th PLC Troubleshooting & SCADA

Related Products:

PLC Training Video Series (10 DVD Set w/ workbook)

PLC Programming Basics Certificate Course

Electrical Troubleshooting Skills Course

Infrared Thermography Training & Certification

VFD Trainer Freq Drive Training Course

Related Maintenance Training Bundle:

The PLC Technician