Pump Types Explained

Types of Pumps and Their Application

By Mike Sondalini

If you own, work with, or are studying a water pump, sump pump, pool pump, chemical pump, industrial pump, or any other type of pump, you will find the knowledge in this "Pump Types" eBook of white papers by Mike Sondalini very valuable. Mike gives you insight into the design, uses, installation, calibration, troubleshooting, and maintenance of the various pump types. 21 pages

The white paper begins with a review of the details of the centrifugal pump with pump curves, cavitations, and how to correct the situation from the Centrifugal Pump white paper. In case you have not read that white paper yet. The review is so you will have a better understanding of that type of pump too.

In addition to the centrifugal pump sections, the peristaltic pump (hose pump), metering pumps (dosing pump), gear pumps, helical pumps, and magnetic drive pumps are explained. Of special interest during the industrial design phase, is Mike's cost/accuracy guide to pump types.

Pump Types Explained - Contents:

Magnetic drive pump experiences

Magnetic drive pumps come in three varieties: canned motor pumps, all metal pumps, and plastic-lined metal pumps. They are sealless and cannot leak into the environment. A long, repair-free service life depends on recognizing the limitations of these pumps.

Problems with peristaltic pumps

A peristaltic or hose pump consists of a rubber hose in a bath of lubricant, mounted on the inside of a round track that is squeezed closed by revolving wheels or a sliding shoe. The squashed area moves around the hose and pushes the contents through it. Behind the moving squeezed area a vacuum is formed and draws in more of the contents being pumped. There usually are two squeeze points 180° apart and driven through a gearbox by a motor. This section explains the operation of peristaltic (hose) pumps and gives twelve points to be aware of when using them.

Helical rotor pumps - benefits and limitations

The section presents the benefits of using helical rotor pumps as well as the important factors to consider for a long working life when they are used. Helical rotor pumps consist of a rotor shaped like an elongated corkscrew, which turns inside a stator. The rotor sits inside the stator void and a cavity is formed between the rotor and stator. As the rotor turns, the cavity moves from one end of the pump to the other.

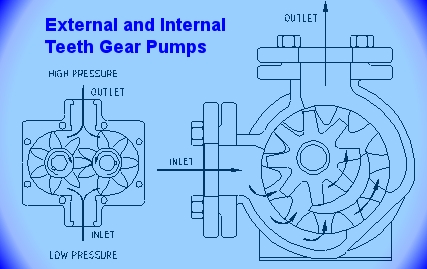

Gear pump operation and maintenance

A gear pump uses two meshing, toothed cogs to force liquid from the inlet of the pump through to the outlet. Being a positive displacement pump there deliver very precise quantities for each revolution and this means they have good dosing characteristics regardless of their speed or the pressure into which they discharge.

Metering & dosing pump operation

Any positive displacement pump can be used as a metering or dosing pump. The purpose of these pumps is to inject a known volume of liquid into a process stream. The primary requirement is that over a given period of time the pump consistently delivers the same amount of liquid.

Learn how to choose the right pump for the job; get a copy of Pump Types Explained now!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$12.50

An Excerpt From Pump Types Explained

"TYPES OF METERING AND DOSING PUMPS"

Positive displacement pumps typically used for dosing duties include diaphragm pumps, peristaltic (hose) pumps, helical rotor pumps, gear pumps, and piston pumps. Piston pumps are the type commonly known as metering or dosing pumps. The degree of accuracy in the delivered quantity is low with diaphragm pumps, better with hose pumps, good with rotor pumps, excellent with gear pumps, and the best with piston pumps.

Pumps from the lower order of the list suffer from back pressure efficiency losses. When they work against a high pressure some of the liquid in the pump does not actually get ejected from the pump. The higher the pressure the less liquid is ejected. This is exactly the opposite of what is required from a metering pump. But for low-pressure, low-accuracy applications they are cost-effective.

Sample from Centrifugal Pump Problems & Answers: Gear Pump Operation-Maintenance

Need more information on pumps? Download the Complete Pumping white paper Set!

Please contact us with any questions.