General Air Compressor Training Course

- Home >

- vocational-training >

- mechanical >

- general air compressor training courses

This compressor tutorial covers most compressors types.

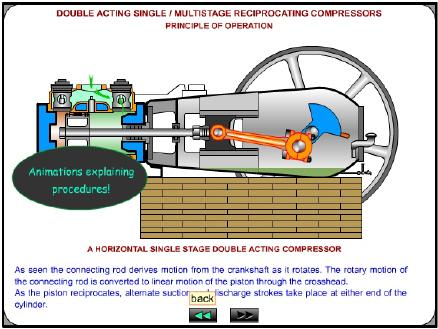

Tap the above picture for the air compressor course demo.

Air Compressor Training Course Demo - Content

general air compressor training course

ESBN: YY1-6798-6040-ac77

Description: (40 hrs)

This animated air compressor training course is a great study guide. It has skill tests for all career assessments, not only industrial ones. Why? Because training covers most compressor types and compressor control systems in the industry. This gas and air compressor course covers the following air compressor types:

- Process gas compressor

- Rotary compressor

- Vertical compressor

- Screw-type compressor

- Centrifugal compressor

- Liquid ring compressor

- Radial compressor

- Reciprocating compressor

- Lobe compressor

This compressor training covers gas and air compressors. But we like to stress its industrial air compressor training value. Ninety-nine percent of all manufacturing industries use one or more air compressors. They are a bottleneck to the entire plant. All plant support staff must know how their air compressor works. They must also maintain their control systems. The compressor training software prints out a certificate upon completion.

- Basics & principles of compressor - working

- Various industrial compressors described

- Detailed coverage on reciprocating, centrifugal & screw compressors

- Extensive 2D / 3D Graphics, Models and Animations

- Skill tests, Certificate printouts

Who Can Benefit:

Untrained students and maintenance staff will find this training on air compressors helpful. It will boost their knowledge and confidence in maintenance work. Those with prior training may find this program a good refresher. They may also learn important information outside of their original training.

Hardware Lock:

This course is also available using a "Hardware Lock" licensing method. Many users want to use the software on multiple computers. For example, they want to work with it on both their office and home computers. This Hardware Lock method allows users to install the software on as many computers as they like. They only need to enter the key on whichever computer they want to use the software. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

You can also ask us to embed your company logo in the training software for the hardware lock option.(Please note the URL of your company logo in the comments when ordering, or email your logo to us to use this feature.)

We will send an email confirming the order within 24 hours after purchase. If you ordered a downloadable version, check your email. It has the download link and activation code. We send a second email with tracking info if you ordered one of the shippable versions.

Download (1 Installation on 1 PC, Unlimited users, 1 User at a time.) $149

1 Hardware Lock (Unlimited Installations, Unlimited number of PCs, 1 User at a time.) $349

1 Network Hardware Lock (Network Installation, Unlimited number of PCs, 10 Users at a time.) $1049

1 Network Site License (Network Installation, Unlimited Simultaneous PCs and Users) $2100

Schools or companies needing a SCORM version of the above site license, please contact us and request a quote.

Course Table of Contents

1. Introduction to Compressors

What is a Compressor?

How Compressors work?

Compressor Classification and Type Selection.

Skill test and assessment

2. Different Types of Compressors

Dynamic

2.1.1. Ejector

2.1.2. Radial (Centrifugal) Compressor

2.1.3. Axial Compressor

Positive Displacement

2.2.1. Rotary

Sliding Vane Compressor

Liquid Ring Compressor

Screw Compressor

Lobe (Roots) Compressor

2.2.2. Reciprocating

Trunk type

Crosshead Type

Skill test and assessment

3. Detailed Description of Popular, Industrial Compressors

Operation Principle of Plant Air Compressors

3.1.1. Screw Compressor - Skid Mounted.

Screw Compressor, Principle of Operation

Control System and Lube oil circuit

3.1.2. V - Type, Trunk and Crosshead Compressor - Skid Mounted

Multi Stage, Trunk and Crosshead, Principle of Operation

Air and Cooling Circuit

3.1.3. Horizontal, Balanced, Opposed, Multi Stage Compressor

3.1.4. Skill test and assessment

3.2. Operation Principle and Maintenance concepts of Process Gas Compressors

3.2.1. Double Acting, Single and Multi Stage Reciprocating Compressor

Principle of Operation

Lubrication of Reciprocating Compressor

Crankcase Main Bearing / Con-rod Big End Bearing

Cylinder and Packing Lubrication

Crankcase / Crank Shaft / Connecting Rod / Crosshead

Compressor Valves

Piston, Piston Elements, Rod Reversal, Runout and Piston End Clearances

Stuffing Box and Rod Packing elements

Compressor Cylinder Cooling System / Inter Cooling / After Cooling

Compressor Control System

Capacity Controls

Intake Valves Unloading

Clearance Pocket Unloading

3.2.2. Centrifugal Compressors

Centrifugal Compressor Principle

Capacity of Compressor

Head of Compressor

Surging and Anti Surge

Thrust Balancing

Lube Oil System

Seal Oil System

Component Arrangement

Sealing Arrangement

Dry Gas Seal

Bearing Arrangement

3.2.3. Skill test and assessment

Related Products:

Infrared Inspection of Mechanical Systems

Mechanical Seal and Selection Training

Centrifugal Pumps and Troubleshooting Guide

Hydraulics Training Certificate Course

Industrial Electrical Training Video Course Library

Please click Contact BIN95 to submit your questions and comments.