- Home >

- articles >

- automation >

- pac vs plc

What is a PAC vs PLC?

PAC Controller vs PLC Controller

Lets start with the definition of both.

PAC and PLC Definition:

- PLC (Programmable Logic Controller)

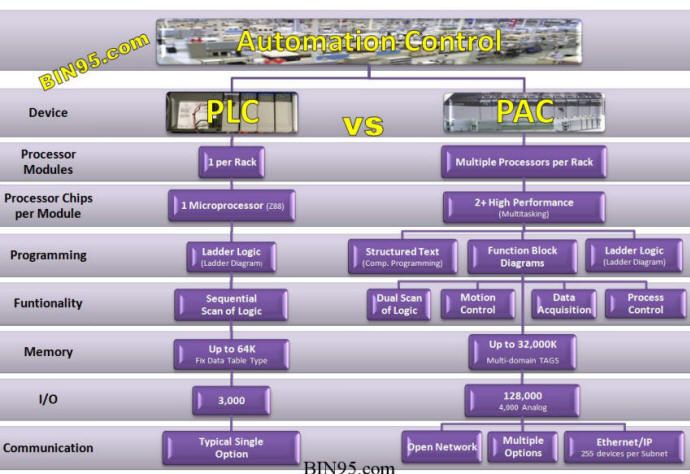

- A Programmable Logic Controller (PLC) is a single microprocessor-based device that automates equipment operation in process and manufacturing machinery, infrastructure, and transportation control. Designed to replace relays and timers, it uses electrician and maintenance-friendly ladder logic to program a sequence of events and reactions via real-world input and output devices.

- PAC (Programmable Automation Controller)

- A Programmable Automation Controller (PAC) is a two- or more processor-based device like a personal computer (PC). It is a PC merged with a PLC that uses multitasking capabilities to automate the control of one or more pieces of equipment. The ARC Advisory Group defined the term PAC in 2001.

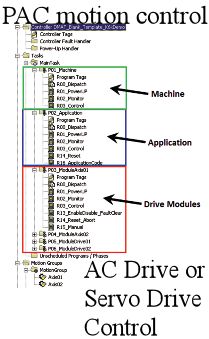

While the PAC possesses PLC capabilities, its hardware architecture and software prioritize user-friendliness for IT/Computer Programmers. Other differences include multitasking, multiple processor modules per rack, multiple programming languages like structured text, distributed control system (DCS), Tag-based addressing, motion control, and standard PC networking like Ethernet, to name a few.

PAC PLC Training Perspective:

Many maintenance, engineering, and even some college instructors refer to a PAC as a PLC. Some correctly argue that your terminology does not matter if the device meets your automation control needs. However, when referring to PAC controller training, it is essential to distinguish between a PAC and a PLC.

It is common for maintenance technicians and industrial engineers to have only learned and experienced PLC Ladder Logic. Their confidence and competence may be high until they encounter a Programmable Automation Controller in the field. Then, they experience a huge learning curve, costly downtime, and sometimes even safety incidents. The main cause is the vast difference in the PAC's advanced architecture and sometimes a different programming language than Ladder Logic, like Structured Text programming.

We will use the Allen Bradley/Rockwell brand of controllers to demonstrate the difference here. Not only do they make the difference easy to see, but they are also the most straightforward PLC brand for students to learn on.

To help differentiate between the two, the AB PLC controllers are models SLC500, Micrologix, and the old PLC5. Their PAC controller is ControlLogix, CompactLlogix, and the FlexLogix.

What is a PAC, verses a PLC? Example video using the Controllogix PAC Controller.

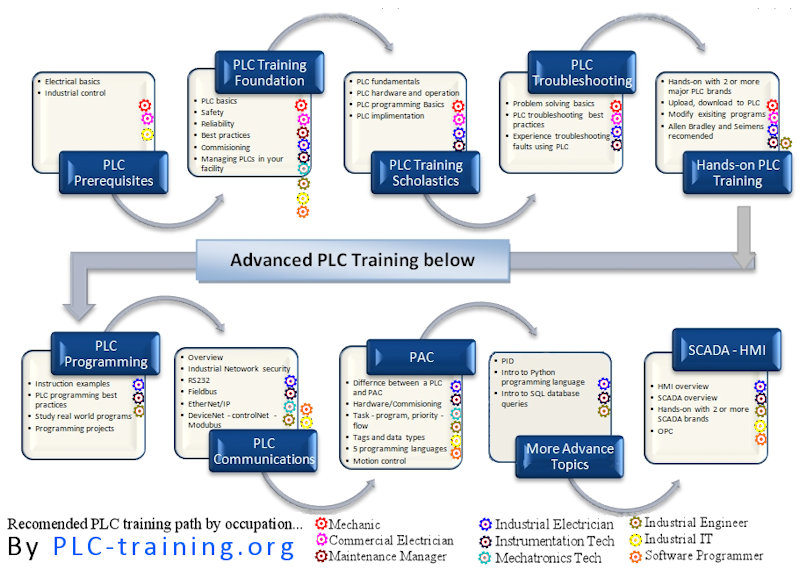

When discussing training, it is essential to understand and communicate the vast technological differences between the PLC and PAC. We always recommend learning the basics and ladder logic on the easier PLC before learning the PAC controller. This approach results in a smaller learning curve, greater understanding, and longer retention.

We strongly recommend 40 hours of onsite hands-on PLC training for your employees, emphasizing PLC safety, reliability, and best practices training relevant to maintenance and engineering working with PLCs in the real world. For hands-on, keep the class size to 6 or fewer employees to increase instructor knowledge to employee transfer. If a training provider were only to provide a presentation-style session and only deliver academic knowledge that anyone could find in a manual, it would only take about 16 hours. While it would be education, it would not be training that covers PLC safety, reliability, and best practices in-depth enough to reduce downtime and other risks adequately.

For companies, we recommend that their employees first take our onsite PLC course (1 week). This critical training is to establish a firm foundation on which to build. Only then have your employees move on to the more advanced topic of PAC training onsite (1 week).

For individuals seeking training on their own, we recommend our software-based PLC Certificate course (40 hrs.), followed by the PAC Certificate course (30 hrs.). They have interactive simulations built into the software for a little hands-on experience not found in most other distance learning courses.

Companies and individuals should also consider our Automation Specialist Training Course Bundle. The bundle includes the PLC, PAC, and courses on ancillary devices and topics like HMI, VFD, Troubleshooting, etc. And you save 32% by bundling the courses.

In contrast to PLC training, the same level of PAC training requires PLC training and PAC overview training, Motion control training specific to that PAC vendor's software, computer programming training for working with structured text (a Pascal-like computer programming language), etc., networking training and network security training. So training for an advanced topic like PACs will start at 80 hours and up, depending on each employee's past training and experience in PLCs and computers.

Side Note: In BIN95.com's Onsite PLC training, a couple of the objectives are "to be able to modify existing PLC programs and identify best-practices PLC programming before you purchase new equipment...". After reviewing the ISA organization's website, they recommend an additional 40 hours of training in the five programming languages a PAC uses after the general PLC PAC training. Then, they recommend additional training classes on networking and networking security. So, it is well over 80 hours to get to that same competence level with PACs. ISA's recommendation furthers the point that the learning curve for the PAC is much greater than it is for the PLC.

If you are already a trained IT/Computer Programmer, you could get by with our PLC training, PAC overview training, and studying the motion control part of the PAC software's manual. But suppose you are a maintenance professional or engineer with little or no IT/Computer programming training. In that case, you will need the training mentioned previously to work with PACs safely and reliably.

This training consideration is essential because most end users still need to know the technology and precautions required for their specific machines in their process and manufacturing facilities. We have had customers request PLC training, and when reviewing their machine program to customize that training, we found that the OEM programmers did not use PLC ladder logic, as they had a PAC. It was all programmed in the computer programming language called Structured Text. However, the customer thought they had a PLC controller, so they requested PLC training instead of PAC training.

We have also seen another scenario where the company placed the IT department in charge of a PAC controlling a machine because it had an Ethernet port on the PAC. However, the IT person had no PLC training or idea of how dangerous I/O forces were when they created windows to force I/O access from any workstation on the company network. They just thought it would be convenient for them and the maintenance department.

Below is the PLC Training Org learning path for automation training by occupation. Seeing where a PAC controller falls within the learning gives additional perspective on the difference between a PLC and a PAC. You can also clearly see how one's particular occupation dictates the necessary training.

A third scenario to consider is that many companies have placed PLC responsibilities on very bright maintenance mechanics who can peck around on the computer while working with PLCs but have yet to gain any other computer experience. So, the difference between the PLC and PAC learning curves will be much more significant in this scenario. So, when referring to training, it is essential to call a PAC a PAC, not a PLC.

So do yourself, your employees, and your company a favor and get the PLC safety, reliability, and best practices training at BIN95 before learning the much more challenging PAC. That is excellent advice for all maintenance, engineering, instrument techs, and IT personnel who will eventually work with PLCs and PACs.

The external resources referenced at the bottom of the page confirm that PACs exist and that there is a vast difference between PLC PACs. As do these organizations and the many PAC controller brands. Organizations such as ARC Advisory Group, International Society of Automation, and PLC PAC vendors, like Rockwell Automation, Siemens, GE, Mitsubishi, Schneider, National Instruments, Opto 22, Advantech, etc.

OK, here is one last comparison of the PAC-PLC difference...

A PLC is to a PAC as an HMI is to SCADA

As SCADA is to HMI, the Programmable Automation Controller(PAC) is to the Programmable Logic Controller (PLC). Just like the PAC can do everything the PLC can do, the SCADA software system can do everything that the HMI can do; the PAC can do everything the PLC does. However, just like an HMI does not perform all the functions that SCADA can, the PLC can not perform all the functions a PAC can.

PAC vs PLC FAQ:

What is the difference between PLC and PAC?

The main differences are that the PAC can multitask and has multiple programming languages, motion control, and standard PC networking. PLCs only have a single scan cycle and typically only use the Ladder Logic programming language.

What is the difference between PLC PAC & DCS?

The PLC is a ladder logic controller that evolved into the Programmable Automation Controller (PAC), designed to be a modern-day Distributed Control System. The PAC replaces the old, costly, difficult-to-modify, less secure proprietary DCS systems. The PAC networks PLC and PACs to the PAC vendor's SCADA software on any standard computer. DCS are often old, customized computers and software that network a facility's PLCs.

What is a PAC control system?

A PAC control system comprises multiple PACs networked and connected to SCADA or other computer software. PLCs and other control devices may also be on the network—PACs used for ICS or DCS.

What is a PAC controller?

A Programmable Automation Controller (PAC) is a two- or more processor-based device like a personal computer (PC). It is a PC merged with a PLC that uses multitasking capabilities to automate the control of one or more pieces of equipment. The ARC Advisory Group defined the term PAC in 2001. Multiple PACs are networked and used as an ICS or DCS.

Are PAC controllers better than PLC controllers?

It depends on the application. A PLC is better because it is easier to use, maintain, and modify and is much less expensive for applications such as single machines, lines, or processes. A PAC is better for creating industrial control systems for multiple machines and processes, data distribution, and networking.

Is PLC a processor or controller?

A PLC is a modular controller. It has one module [card] called the processor module, with a microprocessor chip at its heart. In contrast, the PAC is a modular controller with multiple processor modules in one rack. Each PAC processor module contains one or more full processor chips, like a computer's CPU.

External Resources:

Opto 22 - What is a programmable automation controller (PAC)? opto22.com/support/resources-tools/demos/what-is-a-pac

AB/Rockwell - PAC RSLogix 5000 series rockwellautomation.com/en-us/products/hardware/allen-bradley/programmable-controllers.html

(You may reference portions of this article as long as an active link to the original webpage is present. Otherwise, this material is copyright protected.) |