RSLogix 5000 Troubleshooting vs. PLC Troubleshooting

- Home >

- articles >

- automation >

- rslogix 5000 troubleshooting

RSLogix 5000 Troubleshooting & PLC Troubleshooting and Maintenance:

I have been teaching professionals how to troubleshoot with a PLC and industrial automation for 25+ years. Most of the time I've found that if someone says they are using PLC/PAC software and asking about troubleshooting PLC, they are referring to how to troubleshoot equipment and processes using that software, not how to troubleshoot the PLC Allen Bradley or Rockwell software itself. As the controllers are very reliable, and the problems encountered exist external to the PLC most of the time. So here, I’ll focus mostly on how to troubleshoot equipment using RSLogix 5000 in this article.

First before moving on to PACs (RSLogix 5000, Controllogix, CompactLogix, etc.), Learn the PLC (RSLogix 500, PLC5, SLC 500, Micrologix, etc.).

Although our RSLogix 5000 training software and books cover basic fundamentals of troubleshooting equipment using PLC/PAC, we are able to deliver more in-depth troubleshooting training with our instructor-based classes during Onsite PLC Training because our instructors have years of experience in plants facing the same issues you will face out in the real world, and they can pass on that knowledge about issues they know what you are most likely to run into.

Because we have been specializing in PLC training for 25+ years, our instructors can cover what are the most common problems you will face by prioritizing what is most likely to occur, so you can get the most valuable information and techniques out of our automation control training. We teach you things the OEM doesn’t even know, or say. That is why we get so many college instructors in our classes. They too need that real-world PLC troubleshooting experience knowledge transfer, so they can pass that real-world knowledge on to their students too.

All that being said, on to the meat and potatoes. Our best practice advice is to master PLC (RSLogix 500) before moving on to PAC (RSlogix 5000), because of the difference between PLC and PAC. A PLC is much easier to troubleshoot equipment with than a PAC. First, the PLC is much simpler. Electricians are usually the ones doing troubleshooting, so they relate to ladder logic, plus, the RSLogix 500 software has a whole array of troubleshooting tools as does the RSLogix 5000 troubleshooting which make Studio 5000 logix designer a little less of a challenge.

Rockwell Automation Software Maintenance and Troubleshooting

In our on-site PLC/PAC training classes, we teach techniques utilizing the RSlogix 500 software, where most equipment problems can be troubleshot in 15 minutes, even if you are not familiar with the equipment or PLC program. PAC/RSLogix 5000 maintenance and troubleshooting is much more complex, especially if the programmer used one of the 4 other programming languages like Structured Text. Plus, the PAC’s complexity makes it more likely you will have issues with the PAC, software, or program itself, as opposed to simple PLC troubleshooting and maintenance. So when troubleshooting equipment with Rockwell Automation software, or other PAC software like Siemens, you have to additionally consider whether the problem is with PAC itself, and not some sensor or other external problem.

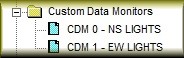

So, with a PLC (RSLogix 500) most troubleshooting can be done in about 4 minutes, tracing back through the logic using 'Find All'. This is to find out which sensor, limit switch, or other devices out in the real world is causing the problem with a machine or process. We simplify it for you. Watch the PLC Troubleshooting Training Video. Find Faults In Just Minutes! For more cumbersome troubleshooting like intermittent problems, RSLogix 500 has great tools like the Histogram, Custom Data Monitors, trend charts, writing your own diagnostics rungs using Latch bit, etc. With RSLogix 5000, it will depend on what version you have, and whether they added that troubleshooting feature back into the software or not.

One example of real-world troubleshooting we teach, which is not in books or software, is using the RSLogix 500 program "Compare Tool". Compare Tool may be in your version of RSLogix 5000, or as a separate software for PACs. Or you might not have the tool if you are using PACs, instead of PLCs to control your machinery. Those not spending years maintaining a PLC/PAC-controlled facility may not be aware of the common scenario of one employee on one shift changing the program, and the rest don’t know it. If the troubleshooter suspects that, they can use the program to compare and once again within about 4 minutes find the problem. With PAC/RSLogix 5000, machines have been down for hours, even days, not knowing someone changed the program because there are just so many other possibilities and complexities with a PAC.

System Data Tables and other data tables found in a PLC, especially inputs and outputs data tables, are great troubleshooting tools too but are not in PACs (RSLogix 5000). This is another major factor contributing to the use of PACs resulting in increased troubleshooting and downtime. In BIN95’s instructor-based PLC training, we also teach best practices in writing PLC programs, so attendees can identify if they are being used before purchasing new machines or systems controlled by PLCs. Having a program that was written using PLC programming best practices, with the end user in mind greatly reduces troubleshooting time. The end user being the customers who has to maintain equipment for the next 10-20 years.

That leads to another area of PAC/PLC troubleshooting training that greatly decreases downtime, by both the reduction of PLC troubleshooting time and the number of times troubleshooting is even necessary. Another very important area BIN95 teaches that is not covered in books, OEM courses, College, or training software is "Best Practices" in Control Automation management. Procedures and Policies developed from decades of experience increase reliability and safety while reducing downtime and the need to troubleshoot in the first place. When it comes to PACs like RSLogix 5000, sound management policies and procedures are even more critical due to incompatibility issues with the various Logix Desginer version number and controller firmware numbers. Something that is hardly ever a concern when working with PLCs.

So, in summary, in order …

- Master PLC troubleshooting before moving on to PACs.

- Learn PAC/PLC Best practices.

- Learn to trace back through PAC/PLC program using Find All or Cross Reference.

- Learn troubleshooting tools provided in RSLogix 500 and Studio 5000 logix designer

IE: Find all, Histogram, Data Tables, Trend chart, custom data monitors, program compare, etc. - Learn to write diagnostic rungs using Latch bit, Move and Copy instructions.

- Learn BIN95's best practices in working with and managing your facility’s control automation.

- If unavoidable to use a Force for troubleshooting, know the safety steps first.

The above real-world knowledge can only be passed on to you or your company’s team via BIN95’s Onsite training. Not even a PLC troubleshooting simulator can teach much of the PAC/PLC troubleshooting tips and tricks our instructors pass on. Although the PLC Troubleshooting Simulator will help you gain years of experience in troubleshooting the PLC itself. The troubleshooting PLC circuits download (simulator) is generic in nature, but has a lot in common with how to troubleshoot PLC Allen Bradley, and gives you a lot of experience with PLC fault finding techniques. For troubleshooting the PAC itself, you’ll need to reference a Compactlogix or Controllogix troubleshooting guide.

Hope this article gave you a heads up. Request a free quote for onsite PAC – PLC training so you and your company can greatly reduce downtime.

© Business Industrial Network and https://bin95.com, 2017 -2026. Unauthorized use and/or duplication of this material without express and written permission from this site’s author and/or owner is strictly prohibited. Excerpts and links may be used, provided that full and clear credit is given to Business Industrial Network and https://bin95.com with appropriate and specific direction to the original content.

TOPICS: Industrial automation:PLC troubleshooting: How to troubleshoot with a PLC-RSLogix 5000 troubleshooting.

All trademarks and trade names are property of their respective owners.