Troubleshooting FAQ for New Electrical and Instrumentation Technicians

- Home >

- articles >

- electrical >

- instrumentation technician troubleshooting

Technicians help ensure the correct functioning and reliability of industrial automation systems. Unplanned downtime can hurt production and profits. So, electrical and instrumentation technicians must excel at troubleshooting instrumentation issues.

This FAQ is for instrumentation and electrical technicians and students. It answers common troubleshooting questions. It also provides best practices and causes of failure. The tools for diagnosing and fixing electrical and instrumentation problems are below. This FAQ will help you, whether you are new to the field or looking to improve your skills. It may also serve as a refresher for electrical engineering technicians. It will help you tackle the challenges of troubleshooting instrumentation.

ARC estimates that unplanned downtime cuts 20% of production in the process industries. A single unplanned shutdown can wipe out your plant's profit for the year.

REF: NAMUR NE 107 recommendations come to the United States – Larry O'Brian

These questions often come up in training, interviews, or day-to-day work for technicians in the field.

Troubleshooting FAQ List ⬇️

1. What are electrical and instrumentation technicians expected to troubleshoot?

E&I Techs troubleshoot automation control equipment and its components. This includes fluid power and sometimes even electronics, computers, and networks. Instrumentation technicians tend to get more control loop troubleshooting experience.

E&I Techs Troubleshoot

- 🔄 Control loops

- 🌡️ Analog and discrete components

- 🤖 Automation control equipment

- 💧 Fluid power equipment

- 🔌 Electronic equipment

- 💻 Computers

- 🌐 Networks

2. What are the four steps to equipment repair?

The four steps to equipment repair are troubleshooting, fixing, verifying, and preventing. Preventing the same issue again requires an RCA to find the breakdown's root cause.

Step 1 - Troubleshoot: Find the problem.

Step 2 - Fix it: Adjust, repair, or replace the faulty device.

Step 3 - Verify: Verify that you have fixed the problem.

Step 4 - Prevent: Use Root Cause Analysis to prevent the recurrence of the problem.

3. What are the best troubleshooting methods for electrical and instrumentation technicians?

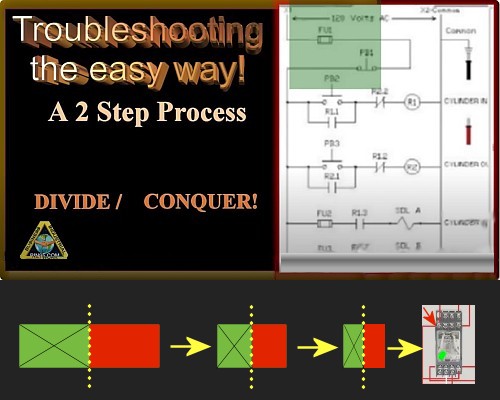

Divide and conquer is the best troubleshooting method in most industrial processes. Also, it is the most used. The second-best troubleshooting method is the substitution method, intuition, and using OEM support. The shotgun troubleshooting approach is, unfortunately, also popular.

The best methods in order are:

- Divide and conquer

- Substitution

- Intuition (if a very experienced troubleshooter).

- OEM support (could cause extra delays).

- Shotgun (not good, but a common practice).

Shotgun Troubleshooting Example

Resetting a breaker without finding what caused the breaker to trip.

The video below is an example of using the divide-and-conquer troubleshooting best practice.

Get the Electrical Troubleshooting Simulator used in the video above and practice on the 26 faults. The more you practice, the more your troubleshooting skills will improve.

4. What troubleshooting test equipment do electrical and instrumentation technicians use?

Meters - True RMS and milliamp capable - top the E&I tech's toolkit for diagnostics. They also use various calibration equipment for both electrical and fluid power. The computers they use are for automation control troubleshooting, too.

Electrical Test Equipment:

- Volt Meter (TRMS)

- Milliammeter (mA)

- Process Calibrator

- HART Handheld Communicator

- IR Thermometer

- Wire Mapper

- Fieldbus and Profibus PA monitor

- Windows laptop with PLC programs on it

- Storage Oscilloscope

- LAN Tester

Hydraulic and Pneumatic Test Equipment:

- Pressure Calibrator/Recorder

- Dead Weight Tester

- Calibration Gauge

- Pressure Module

5. How do you troubleshoot common instrumentation issues?

After investigating, check the maintenance logs for similar problems. This will help you troubleshoot common instrumentation issues. Then, use the divide-and-conquer troubleshooting method until you locate the problem. After repairing, be sure to document and perform a root cause analysis.

The 5 steps in troubleshooting are:

- Investigate:

- Talk with operators.

- Verify the equipment is being used as designed.

- Check if the problem is repeatable or intermittent.

- Consider potential external causes such as the environment, interfaced equipment, power quality, etc.

- Check if the same or similar problems occurred before in the maintenance records.

- If the same problem occurred in the past, perform an RCA (Step 5).

- Divide and conquer. A common first step in industrial processes is manually testing the instrument loops or electrical equipment.

- Inform all involved that you will be conducting the trial.

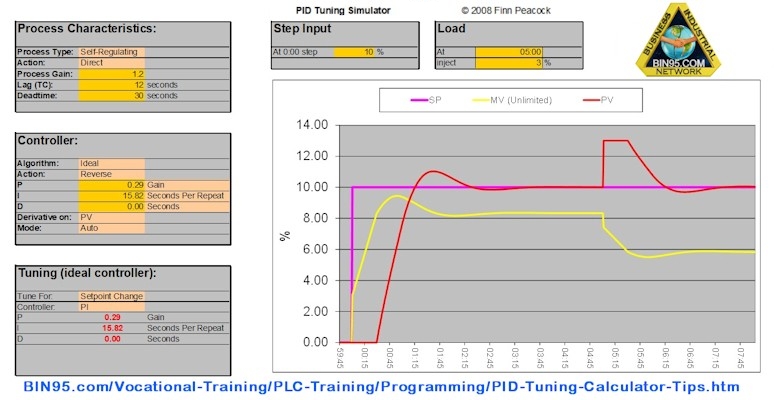

- You can tune the PID if it works through manual effort. You may also examine the auto mode of the electrical controls or ladder logic.

- Keep dividing the process or ladder logic into parts until you find the problem.

- Repair, document, and do a Root Cause Analysis (RCA). It will stop the problem from happening again.

The screenshot of the PID tuning simulator above shows some variables. The PID Tuning Blueprint Training Kit makes the tuning process easy.

6. What are the common causes of equipment failure in electrical and instrumentation systems?

Mechanical failures are the most common causes of electrical and instrumentation system failures. Followed by high-current devices and low-current devices. Solid-state devices are least likely to fail.

The physics behind failure results in the following common causes of equipment failure. Also shown is how the physics relates to PLC failures.

In order of most likely to least likely.

- Mechanical

- Electro-Mechanical

- High Current

- Low Current

- Solid State

The physics translates to PLCs as:

- External to PLC

- Output Cards

- Input Cards

- Power Supply

- Backplane

- CPU (Processor Card)

The environment can change the order of the above. Heat, vibration, dust, humidity, EMF, or the operating environment. Those darn forklifts.

Note that low-amp PLC input cards are least likely to fail. If they do, RCA will show that the sensor/wiring external to the PLC caused the input card failure. The external fault will usually involve a short circuit.

7. What are common instrumentation faults?

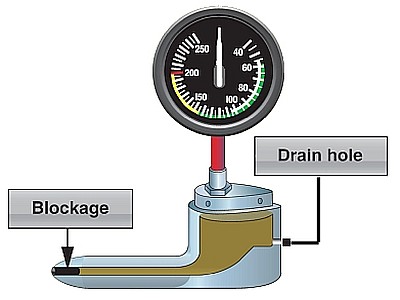

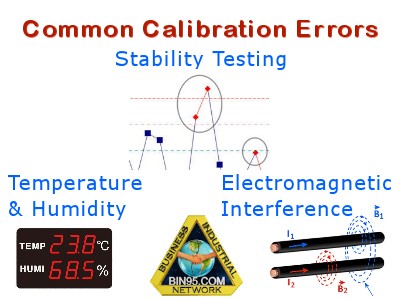

The most common instrumentation fault is the 4-20 mA loop fault. The loop fault might be a short, open circuit, or insulation issue. It could also be a power problem. Common causes include component failures and calibration errors.

Common instrumentation faults are:

4-20 mA loop faults

(shorts, opens, insulation issues,

power supply, etc.)

Component failures

(blocked instrument line included).

Calibration errors.

8. How do you perform a loop calibration on instrumentation devices?

First, check the wiring and power supply. Then, perform a loop calibration on the instrumentation device. We send a range of 4-20 mA signals and verify the output reading. Finally, adjust the calibration if needed and test again.

The steps to perform a loop calibration are:

- Tools: documents, multimeter, and loop calibrator.

- Check that the wiring and power supply are correct.

- Connect the loop calibrator in series with the instrument.

- Send a range of 4-20 mA signals and verify the output reading from the instrument for each input value.

- If the output is out of tolerance, adjust the calibration.

- Test again.

- When finished, document calibration and connect back to the control system.

9. What types of sensors are commonly used in industrial applications?

Process industries use pressure, flow, and level sensors the most. Manufacturers use proximity, temperature, and optical sensors the most.

In industrial applications, several sensor types monitor and control processes.

Here are some of the key sensor types:

Temperature Sensors

Pressure Sensors

Flow Sensors

Level Sensors

Proximity Sensors

Displacement Sensors

Optical Sensors

Humidity Sensors

Gas Sensors

Vibration Sensors

To learn a little bit more about proximity sensors, see the demo video for Control Instrumentation Training Course.

10. What are the main differences between analog and digital signals in instrumentation?

The main difference between instrumentation analog and digital signals is that analog varies volt/amps while digital varies 1s and 0s. Also, analog signals are susceptible to electrical noise. Digital signals, not so much.

Analog vs Digital Signals

- Analog signals vary in voltage or current in proportion to the measurements.

- Digital signals use 0s and 1s to binary encode the values measured.

- Analog signals are more susceptible to interference, while digital signals are immune.

- Digital signals provide better accuracy and resolution than analog signals.

11. What reading indicates a problem with a 4-20 mA sensor loop?

Any reading outside the range of 3.8-20.5 mA indicates a problem. Also, the 24 V power supply should be within 21 V and 28 V DC.

Troubleshooting the 4-20 mA sensor loop

- A measurement of 3.8-20.5 mA is acceptable.

- 20.5 – 22.0 mA or between 3.6 – 3.8 mA indicates a bad transmitter.

- Anything above 22.0 mA is a short, and below 3.6 mA is an open.

- The 24 V DC should be between 21 V and 28 V DC.

12. What is the importance o grounding in electrical systems?

Grounding is crucial for the safety of both people and equipment. Grounding is also essential for maintaining signal integrity in instrumentation. Grounding reduces instrumentation signal noise and interference. Grounding is vital for accurate measurements and for control systems to work.

Instrumentation Troubleshooting Notes:

What are common instrumentation connection symbols on prints?

----//----//----//---- Pneumatic Signal

-- -- -- -- -- -- -- -- Electronic Signal

----L----L----L---- Hydraulic Signal

----~----~----~--- Guided Electromagnetic Signal

Maintenance, instrumentation, and electrical technicians ensure the industrial system's operation. Troubleshooting is vital in this field and impacts production and profits. E&I technicians fix instrument problems using the right tools and best practices. The above references, including RCA, aim to improve E&I technicians' troubleshooting skills. As technology evolves, electrical technicians must stay informed. The latest techniques and equipment will help them tackle challenges. This will boost efficiency and profits.

You may also want to take our 10-question Industrial Instrumentation Technician test. It includes six extra Frequently Asked Questions (FAQs) related to the field.

Also, our new 20-question Instrument Level 1 Technician NCCER practice test is available.

More related articles ...

Electromagnetic Induction Applications for the Instrumentation Technician

Instrumentation and Process Control Training

PLC Troubleshooting Training Video - Find Faults In Just Minutes!

Related training...

The Technician's Automation Training Course Bundle

Hazardous Area Instrumentation Course