Rotating Machinery Testing:

- Home >

- articles >

- mechanical >

- rotating machinery testing

Rotating machinery questions that need to be asked.

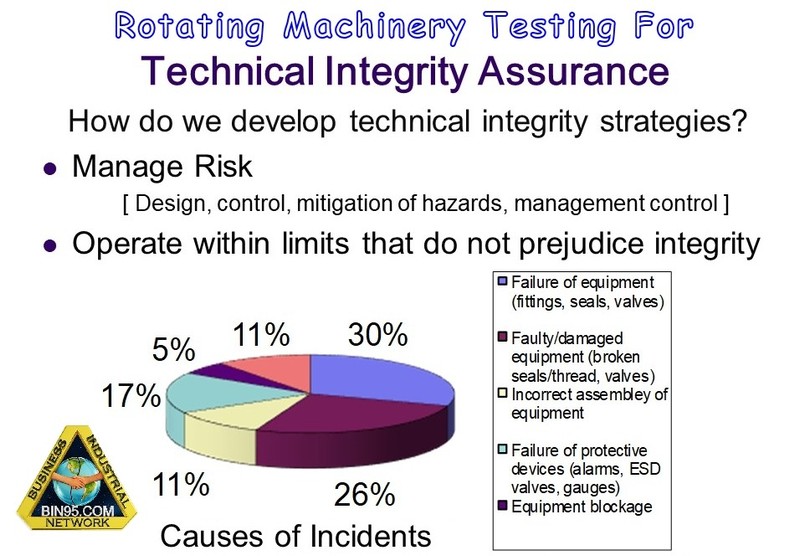

These rotating machinery testing questions need to be asked if you want to develop sound technical integrity strategies that result in reliable and safe rotating equipment.

Rotating Equipment Testing of Integrity Assurance:

Use formal procedures, safe systems of work, technical authority for changes on each brand of rotating machine, and rotating machine knowledgeable engineers to protect integrity. Modifications that result in changes to drawings and other relevant rotating machine documentation need to be reflected in those documents, and the people trained, or else the rotating machine will be operated or maintained incorrectly. A plant needs procedures for checking the integrity of control systems and computer software, document management, and changes recorded and authorized. (Especially the commonly overlooked program changes for both the machine's CNC controller and PLC controller) Audit trail demonstrated!

The Questions You Should Ask Yourself ...

If the technical integrity of my rotating machinery rests on a good initial design, operations feedback, thorough hazard studies, competent risk assessment, and high construction standards...

Do I have systems to give me assurance on these aspects?

Am I tracking them, or have I clearly delegated this responsibility?

If the technical integrity of my existing rotating machinery rests on good maintenance/inspection plans, corrosion control, non-destructive testing, etc., and good maintenance/inspection execution, isolation, repair work, etc.

Are my systems ensuring that both aspects are under control?

Are they independently audited?

Do I know the progress against the plan, am I aware of the backlog?

If not, is the responsibility clearly delegated to an individual?

If many incidents result from poor control of change (drawings, procedures, software, people).

Are the systems on which I rely subject to update, development, and review?

Does the workforce have confidence in them/help in their development?

Am I clear that all change in my organization is approved by a coherent system, and is documented?

Rotating Machinery Lifecycle:

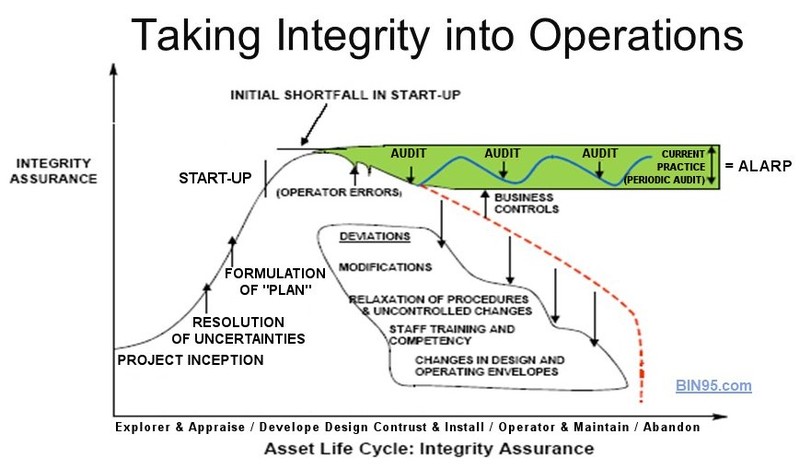

The diagram in Figure 2 indicates what happens to integrity assurance as the plant's rotating machinery progresses through its lifecycle. Integrity starts developing at the feasibility and project phases progress, rising as the design becomes more certain and details involving machinery use, operation, and maintenance accrue. Once the rotating machinery goes into use, the business systems supporting it begin to deteriorate. As a consequence, the machinery's integrity drops and requires regular efforts to sustain integrity via the use of quality management methods such as auditing and proper testing solutions being implemented.

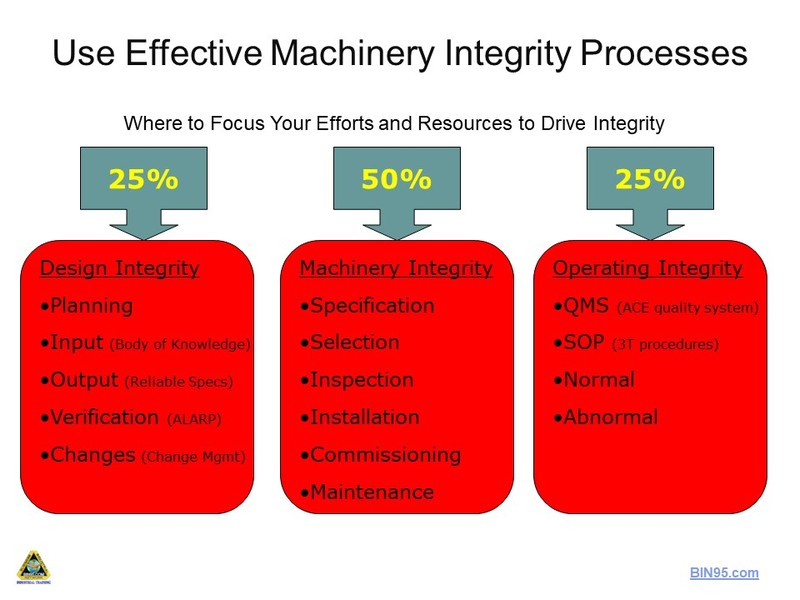

Effective Machinery Integrity Processes:

The bullet points for each list above in Figure 3, indicate what each integrity type contains, and where your focus needs to be to drive reliability engineering integrity. The rotating machinery integrity and operating integrity require the proper testing solutions in place to laser focus your efforts. So the bullet point above "Inspection" is not only referring to visual inspection but also testing solutions common with machinery condition-based maintenance (CBM). A few examples of testing solutions required for rotating machinery are harmonic analysis, vibration analysis, thermography, lubricant testing, voltage and insulation testing of motors, etc. Smaller companies should consider contracting a rotating machinery service company to insure adequate and accurate testing.

I hope this article encourages you to ask the right questions concerning your rotation machinery integrity. To continue learning about structured review audits, and measuring and rating rotating machinery objectives, see day 4 of the Rotating Equipment Reliability Course PowerPoint download.

Related Course:

Reliability and Maintenance Management Training Course PowerPoints

Enterprise Asset Management System Training Course PowerPoints

Total Productive Maintenance -TPM Course PowerPoints