Mechatronics Engineer and Technician

Mechatronics Engineer: Is the USA becoming a "Jack of All Trades" - Master of NONE?

Commentary, about the USA's diluted education and employment in manufacturing:

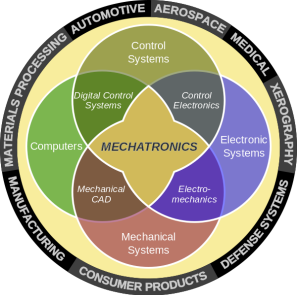

What is "Mechatronics"

In playing devil's advocate to spark controversy and conversation ...In the past, the USA's manufacturing and other industries were set apart from the rest of the world by its innovation and efficiency brought about by education, teamwork, and individual capitalistic drive. In plain English, our young knew the way to a financially secure future was to become a master of their trade. If you had an electrical problem you called a master electrician. Mechanical problem? You called a master mechanic. Need something machined, you asked the machinist. Need electronic device designed, you get an electronic engineer. Need an electrical control designed? You get an electrical engineer.

The mentality was you need something done; it was cheaper and safer to get the right expert for the right job. Common sense told us no-one is an expert at everything. So on multidiscipline projects, you built a team of experts to get the best end results possible. Need a machine designed your team would consist of several engineers, a mechanical engineer, software engineer, electrical engineer, etc. Decades ago the industry combined the maintenance department team from experts in each field, to a single individual into the "maintenance mechanic" or technician. (<< click to learn more) Or one of the other dozen titles employers makeup to refer to one individual who replaced the need for maintenance departments to have a separate employee specializing in electrical, another in mechanical, machinist, etc.

In recent history, this strategy has spread to the engineering disciplines too, with the creation of the job title "Mechatronics Engineer" or "Mechatronics Technician". So instead of hiring 4 experts, a mechanical engineer, and an electrical engineer, and an electronics engineer, and a software engineer, they hire 1, a Mechatronics engineer. Several decades ago the industry found by combining job titles and responsibilities, they could reduce their workforce size and labor cost. Maybe it was not a desire to increase revenue for management and stockholder by reducing the labor force. Maybe a few actually believed you could get even more innovation and efficiency from one individual who knew enough of each discipline to get by and performed all the tasks themselves, instead of having a team of experts.

"Jack of All Trades" - Master of NONE!

Theories of the origins of this multi-skill trend in manufacturing might be insightful, but without the decision-makers being truthful in studies and surveys, that is all they will ever be theories. The Japanese style of management, in their great wisdom, was to have the experts be familiar with the other skills in the industry. But their intent was just to get the expert familiar, not actually combining the jobs into one person. Like having their maintenance and engineers run the machines in the manufacturing plant, to be more familiar. The apartment complex hired a general maintenance man to perform the simpler task of electrical, carpentry, plumbing. But Government regulations required those apartment managers to hire a licensed master electrician, carpenter, plumber to do the major projects.

"No two minds ever come together without thereby creating a third, invisible intangible force, which may be likened to a third mind." - Napoleon Hill, Author

So when you rely on one single individual to do what multiple experts used to, you lose that "third mind", reduce innovation, creativity, and expertise in any one single discipline.

In manufacturing, the government has no such regulations, opening up the door for combining jobs and diluting the industry's expertise. Nobody thinks it is a good thing, or a bad thing, they just accept it as the way it is nowadays. One wears many hats in today's jobs. The field of Mechatronics first introduced by the Japanese (Tetsuro Mori of the Japanese company Yaskawa in 1969) was not intended to replace the mechanical engineer, the software engineer, etc. With an electrical or electronics engineer who knew a little about the other three disciplines. It was conceived to provide the electrical engineer with the extra education needed to be proficient in working with robots. This is in line with Japanese philosophy.

But in the USA, with the mentality to constantly reduce the 10-15% labor cost and put those profits into management and stockholders pockets' it is likely the Mechatronics will be the engineering version of the maintenance technician. With the 10% for-profit colleges and other educational institutions' growth exploding since 1995, that big businesses will welcome new combined job titles that require additional education too.

Those seeking a career in Mechatronics should first have a clear definition of the job description and the pay. (click for the Manufacturing career path to read more.) The go-to source for occupational titles and job descriptions should be the government's OOH. But they list it under a catch-all job title "electro-mechanical technicians", list the pay at $49k, and refer you to "O*net" for any kind of detailed description.

On O*net where they show the pay at $90k, you will find a lot of text, but very little in the way of an actual description for "Mechatronics engineers". That is because for their job descriptions, they cut and paste a template description for similar jobs and the editor quickly changes whatever they may know about that particular job description. That is why on the mechatronics description page you will find "accountant" referred to 3 times when that discipline has nothing to do with mechatronics. You will also find after viewing several of the job descriptions about 60% are the same generic details on all the related descriptions (filler). For example, they list under a handful of tools needed for the job, "bandsaws", under knowledge - "English language", under skills - "speaking, writing". :>)

Also, colleges like to refer their students to Google ad farm sites like Glassdoor when students want to evaluate actual pay they might receive in the mechatronics field. Because the site doesn't have any actual current salaries for the mechatronics field, it will list similar fields such as design engineer or software developer. This may give students a false sense of the actual pay they will receive in the real world.

The most informative site about a mechatronics engineer or technician was not the official government site (OOH), or the website the government recommends (O- net), or the one colleges sent students to for income evaluation (Glassdoor), it was Wikipedia's mechatronics page! That is amazing and sad at the same time.

Views expressed in this commentary section do not reflect any thoughts or policies of Business Industrial Network, and are only the views of the contributing writer. (You may not copy, distribute or reference portions of this commentary. You can link back to this original commentary as a recommendation for others to read. This material is copyright protected.)

Ref: https://bin95.com/articles/opinion/mechatronics-engineer-technician.htm Topics: mechatronics education, mechatronics engineer salary, mechatronics salary, electrical engineer salary, manufacturing engineer, manufacturing engineer job description, manufacturing job description |