Industrial Refrigeration Training

Commercial & Industrial Refrigeration Training Course

In this course, learn the refrigeration and air conditioning cycles. Gain a more in-depth understanding of the basics of air conditioning. Those who repair commercial and industrial refrigeration will value this course. It provides a deeper understanding of industrial refrigeration. This course's knowledge helps techs maintain and repair refrigerators and ACs.

Tap the above for a demo video of the commercial & industrial refrigeration course.

Industrial Refrigeration Training Contents

Industrial Refrigeration Training Certificate Course

ESBN: DR32-134ab-6040-r22

Description: (40hrs)

The HVACR Certificate Course teaches the basics of refrigeration and air conditioning. This course uses graphics and animations. This is to better explain the refrigeration and air conditioning cycles.

This course on refrigeration and air conditioning is comprehensive. It explains in detail the following:

- Dry Bulb

- Wet Bulb

- Dew Point Temperatures

- Coefficient of performance (CoP)

- The heat rejection factor (HRF)

- Sensible and latent heat

- Mollier diagram

- Psychrometric chart.

The course also covers refrigeration and air conditioning components in detail. HVAC components include compressors, evaporators, and condensers. They also include throttling valves, fans, piping, and insulation. The downloaded course is a great reference for fridge and AC repair.

- It is Air Conditioning Refrigeration Cycle Basics, but it has in-depth coverage.

- The content covers both the vapor-compression cycle and the absorption refrigeration cycle.

- This course is for anyone who needs to know about refrigeration and AC systems.

- Includes extensive 2D/3D graphics, animations, skill tests, and certificate printouts.

- It is an excellent start for HVAC technicians.

Who Can Benefit:

The guided tour video shows the details of this course. You will see there is also a complete guide to AC and refrigerator repair. This course will help students and untrained maintenance and engineering staff. Those in process, manufacturing, and building trades may want to take this course. This includes engineers, plumbers, and mechanics. This course is for those who will work with refrigeration and air conditioning systems. And anyone wanting to understand refrigeration and air conditioning systems' basic operation.

Instructors and corporate trainers want to use this material to add to their HVAC course or to design a course. Industrial and building maintenance, mechanical installers, and engineers may need this course. Boilermakers, plumbers, pipefitters, and steamfitters may also need it. This refrigeration course is a great start for aspiring HVAC professionals. It suits those who want to be a mechanic, contractor apprentice, installer, or AC repair tech.

A great supplement to air-conditioning and refrigeration engineering courses.

About the Hardware Lock:

A "Hardware Lock" license also offers this refrigeration and air conditioning course. Many users want to use the software on multiple computers, i.e., at work and at home. This Hardware Lock method allows users to install the software on as many computers as they like. They only need to enter the USB key on whichever computer they want to use the software. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

The hardware lock also has the option for us to embed your company logo in the HVAC training software. To give you that customized feel. (Please note your logo's URL in the comments when ordering. Or, email your logo to us to use this option.)

Testimonial:

Tom Dahmen - Learning & Development Coordinator at Chevron, Niche Refinery, U.S.A.

"Everyone I have shown the material likes it and we would like to build more material around it for fundamentals. To Niche Refinery Training Coordinators, this way we can move forward with upgrading the fundamentals training and have more updated modules to replace our current material."

John E Longden - Petroleum Training Institute, U.K.

"Received the packages. I am trying to think of something to say. It is absolutely splendiferous!! Having used many training modules, I have never seen such high quality CBTs. Top class animations make the course very informative as well as engrossing. This is truly bloody good stuff. I cannot praise it enough."

We will send an email confirming the order within 24 hours after purchase. If you ordered a downloadable version, check your email. It has the download link and activation code. We send a second email with tracking info if you ordered one of the shippable versions.

Download (1 Installation on 1 PC, Unlimited users, 1 User at a time.) $149

1 Hardware Lock (Unlimited Installations, Unlimited number of PCs, 1 User at a time.) $349

1 Network Hardware Lock (Network Installation, Unlimited number of PCs, 10 Users at a time.) $1049

1 Network Site License (Network Installation, Unlimited Simultaneous PCs and Users) $2100

Schools or companies needing a SCORM version of the above site license, please contact us and request a quote.

Industrial-Commercial Refrigeration Engineering Courses

Commercial refrigeration and air conditioning training with animated descriptions.

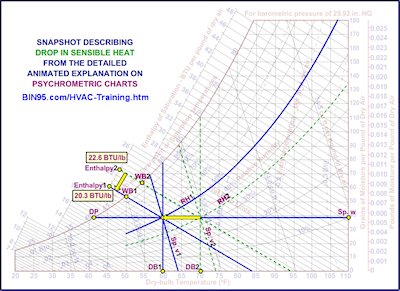

This industrial refrigeration course starts at the basics. But, like all courses in this series, it progresses to the engineering level. The courses, with the charts and calculators, are a complete reference. The screenshot above shows a psychrometric chart. It has an animated description of the state changes. It details basics like molecular change due to heat variations, temperature, and pressure. As you saw in the testimonials above, technical schools and colleges use this course. Its coverage and animations update and supplement their existing HVAC courses.

Air Conditioning Basics Course Contents

- 1 REFRIGERATION BASICS

- 1.1 INTRODUCTION

- 1.2 STATES OF MATTER / TEMPERATURE / HEAT

- 1.2.1 Kinetic Energy / Potential Energy

- 1.2.2 Sensible Heat / Latent Heat / Sub Cooling / Super Heating

- 1.2.3 Changes of State of Matter

- 1.2.4 Temperature Scales

- 1.2.5 Heat Units

- 1.2.6 Enthalpy / Entropy

- 1.2.7 Methods of Heat Transfer

- 1.3 PRESSURE

- 1.3.1 Atmospheric Pressure / Gauge Pressure / Vacuum

- 1.3.2 Boiling Point / Vapor Pressure

- 1.4 REFRIGERANTS / TABLES / DIAGRAMS / UNITS

- 1.4.1 Refrigerant Types

- 1.4.2 Refrigerants Tables

- 1.4.3 Mollier Chart / Pressure - Enthalpy / Temperature - Entropy Diagrams

- 1.4.4 COP (Coefficient of Performance)

- 1.4.5 HRF (Heat Rejection Factor)

- 1.4.6 NRE (Net Refrigeration Effect)

- 1.4.7 Refrigeration Ton unit / EER (Energy Efficiency Ratio)

- 1.4.8 Comparison of Diagrams

- 1.5 AIR CONDITIONING WORKING PRINCIPLE / PSYCHROMETRIC CHARTS

- 1.5.1 Dry Air and Water Vapor (Moisture)

- 1.5.2 Relative Humidity

- 1.5.3 Concept of Drier Air

- 1.5.4 Dew Point Temperature

- 1.5.5 Dry Bulb Temperature

- 1.5.6 Wet Bulb Temperature

- 1.5.7 Psychrometric Charts

- 1.5.8 Sensible Heating

- 1.5.9 Sensible Cooling

- 1.5.10 Humidification

- 1.5.11 Dehumidification

- 1.5.12 Psychrometric Chart - Combination of Heating / Cooling / Humidification / Dehumidification

- 2 AIR CONDITIONING CYCLE / REFRIGERATION CYCLE

- 2.1 WORKING PRINCIPLE

- 2.2 VAPOR COMPRESSION CYCLE / SYSTEM

- 2.2.1 Refrigerant Flow

- 2.2.2 Low and High Pressure Zones

- 2.2.3 Correlation with an assumed System with related Temperature and Pressure Parameters

- 2.2.4 Correlation with NRE (Net Refrigeration Effect)

- 2.2.5 Correlation with Mollier Diagrams and Refrigeration Charts

- 2.2.6 Refrigerant Cycle in a representative Industrial Unit

- 2.3 VAPOR ABSORPTION CYCLE / SYSTEM

- 2.3.1 Basic System

- 2.3.2 Ammonia Water Absorption System

- 2.3.3 Lithium Bromide Absorption System

- 2.3.4 Triple Vapor Absorption System

- 3 REFRIGERATION - AC COMPONENTS

- 3.1 THROTTLING / METERING DEVICES

- 3.1.1 Choke / Capillary Tubes

- 3.1.2 Hand Expansion Valves

- 3.1.3 Automatic Expansion Valves

- 3.1.4 Thermostatic Expansion Valves

- 3.1.5 Low Side Pressure Float

- 3.1.6 High Side Pressure Float

- 3.2 EVAPORATORS

- 3.2.1 Dry Expansion

- 3.2.2 Flooded

- 3.2.3 Bare tube type

- 3.2.4 Finned type

- 3.2.5 Natural Convection

- 3.2.6 Forced Convection

- 3.2.7 Indirect Refrigeration (Secondary Refrigeration)

- 3.2.8 Dry Expansion Chillers

- 3.2.9 Flooded Chillers

- 3.2.10 AC Frosting / Defrosting

- 3.2.10.1 Off-Cycle Defrost

- 3.2.10.2 Electrical Defrost

- 3.2.10.3 Hot gas Defrost

- 3.2.10.4 Reverse Cycle Defrost

- 3.2.11 Evaporator Capacity

- 3.3 CONDENSERS and COOLING TOWERS

- 3.3.1 Air-cooled

- 3.3.1.1 Natural Convection

- 3.3.1.2 Forced Convection

- 3.3.2 Water-cooled

- 3.3.2.1 Double Pipe (tube-in-tube)

- 3.3.2.2 Shell and Tube

- 3.3.2.3 Shell and Coil

- 3.3.3 Evaporative condensers

- 3.3.4 Cooling Towers

- 3.3.4.1 Natural Draft

- 3.3.4.2 Forced Draft

- 3.3.4.3 Induced Draft

- 3.3.5 Condenser Capacity

- 3.3.6 Cooling Tower Capacity

- 3.3.7 Refrigeration Capacity

- 3.3.1 Air-cooled

- 3.4 AC COMPRESSORS

- 3.4.1 Reciprocating (piston) Compressors

- 3.4.1.1 Open

- 3.4.1.2 Semi-Hermetic

- 3.4.1.3 Hermetic

- 3.4.2 Rotary Compressors

- 3.4.2.1 Scroll

- 3.4.2.2 Rolling Piston

- 3.4.2.3 Sliding Vane

- 3.4.2.4 Screw

- 3.4.3 Centrifugal Compressors

- 3.4.1 Reciprocating (piston) Compressors

- 3.5 MISCELLANEOUS

- 3.5.1 Fans

- 3.5.1.1 Centrifugal (Blowers)

- 3.5.1.2 Axial Fans (Propellers)

- 3.5.2 Piping Layout

- 3.5.3 Insulation

- 4. HVAC Skill Tests with evaluation

- 3.5.1 Fans

- 3.1 THROTTLING / METERING DEVICES

Related Products:

Electrical Troubleshooting Training Simulation Software

Infrared Inspection of Mechanical Systems

Gas and Air Compressor Training Course

Hydraulics Training Certificate Course

Industrial Hydraulic Systems and Circuits Course

Hazardous Area Instrumentation Training

Please click Contact BIN95 to submit your questions and comments.