OEM Definition and Training

We specialize in Allen Bradley PLC Training that results in less support time for machines and quicker start-ups.

Glossary:

Definition:

OEM Definition: Original Equipment Manufacturer - The machine, PLC, and software vendors are all the "OEM".

Training Definition: Business Industrial Network defines "Training" as ... Hands-on while evaluating at each step taught and providing additional learning material for continued self-education. We do not consider reading a book, listening to a presentation, etc., "Training". We consider those presentation-only formats to be only education and knowledge transfer.

Business Industrial Network provides on-site, customized Program Logic Controller (PLC training), for your Engineers and Startup Techs. By OEMs having their employees trained by us, the OEM's PLC programs, startups, and machine support will be more end-user friendly. The OEM's customers will receive more value for their money and the OEM will reduce warranty and start-up costs. This is yet another way we are responding to our customer's needs.

Action Required:

1. OEM: Request a quote today for our PLC Training to improve your product and service quality while reducing development, start-up, and warranty cost.

2. Machine End-User: Require that your OEMs employ Business Industrial Network certified engineers and technicians so you receive a more user-friendly PLC program and less downtime during start-up and warranty work.

Item number 2 above makes an important point. OEM end-users are becoming more aware that warranty work on their equipment is not free to them. It often causes them expensive downtime costs. And the end-users are becoming more aware of the "True Downtime Cost"™ (TDC). So by an OEM having Business Industrial Network PLC certified employees, the OEM is gaining a big edge over their competitors.

What OEM customers are saying ...

1. Talking about PLC Vendor OEM: "I took an OEM course a few years back, but they went too fast and taught topics I have never used."

2. Talking about Machine Vendor OEM: "Training consisted of looking over Start-Up Technician's shoulder, and he went too quick explaining very little."

the training solution:

Two Options: Let us train your OEM employees or we can train your OEM End-User.

We can offer you a Train the Trainer solution, where our instructor delivers PLC training to your start-up technicians so they can deliver the PLC training to your customers on-site. We provide originals of training material so your new customer trainer can print copies to give to your customers when you provide the training to them. All training material is developed from an end-user point of view, so your customers see you are delivering world-class training with added value.

A second Training Solution for OEMs is to include our PLC training as part of the start-up package to be delivered to the OEM's customer. We schedule one of our instructors to deliver the PLC training on-site to your customer. Not only does this solution add even more value to your customer, by having a seasoned trainer delivering the knowledge, but our reasonable prices will allow you to see a profit from training, not just the cost of doing business. OEMs realizing that training can be a profit center is relatively new to the industry, but we first introduced the concept and implemented it in 1995.

What sets us apart from your other training options.

- We review and use the actual plc programs you use in your machines.

- We customize the topics, material, and level of expertise to match your current employee's needs.

- We deliver the training in your facility and offer public seminars to better suit your scheduling needs.

- We start with hands-on classroom training, software simulations, and handouts that reflect your actual facility equipment.

- We wrap up the world-class training with a quiz to assess effectiveness.

- We follow up with advice to reduce start-up costs and make your programs more customer-friendly.

- We leave you with a copy of the presentation for review and in-house training of future employees.

We adapt for customer's training room.

RSLogix 5000 training too.

We are the Allen Bradley PLC trainer near you.

PLC training AND evaluation.

PLC training at your facilities.

Our PLC troubleshooting training reduces downtime.

Why on site customized training?

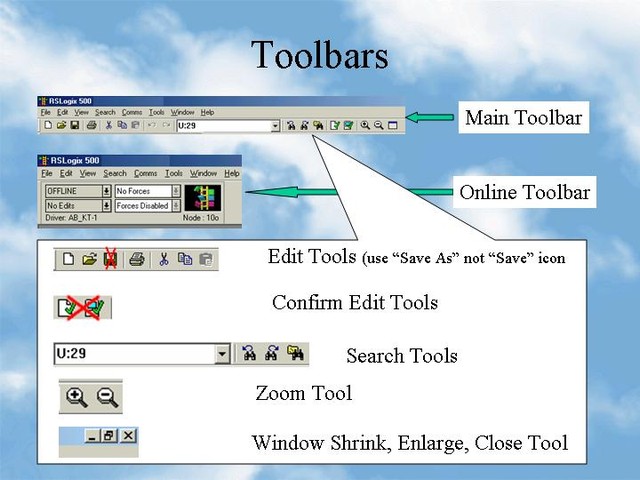

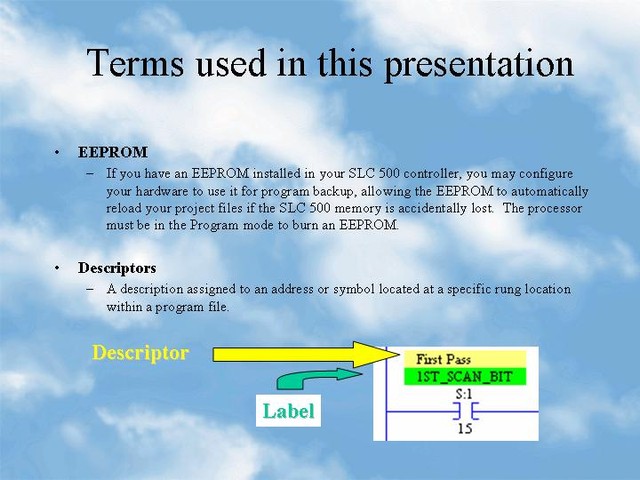

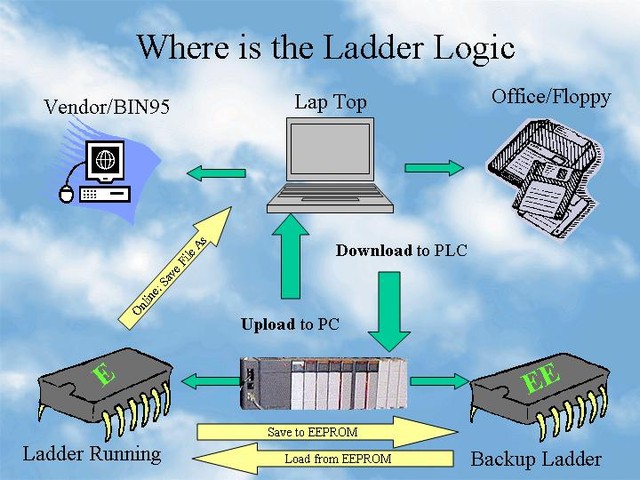

All of our PLC training is Hands-on with actual equipment we provide, but we use PowerPoint's as a guide and for handouts with our legacy PLC training course. Please hover over the images below to see samples of the PowerPoint presentation...

We teach best practices to reduce downtime.

We emphasize documenting PLC programs.

PLC program management and backups reduce downtime too.

Note: With the new Scholastic RSLogix 500 & 5000 courses, students receive printed manuals instead of digital PDF copies of handouts given during the Essentials course.

Your choice:

Legacy PLC Training: RSlogix 500 software, SLC 500/4 hardware.

New PLC Training: RSLogix 500 software, Micrologix 1400 hardware.

New PAC Training: RSLogix 5000 software, CompactLogix hardware.

More about Training; as defined by Business Industrial Network

- Our training standard uses what some refer to as 'Level Three', then our training improves on it to bring it to the 'World Class" / "Best in Class" level.

- Our learning objectives are selected to be the most needed by recipients. (We do not overwhelm students with knowledge they will never use.)

- Our method of delivery is always hands-on, with a workbook or PowerPoint. As experience levels vary; we always provide extra learning material for use in class and for an individual's own continuing education. The instructor shows how to perform a task, then everyone does it, while the instructor makes sure everyone performs the task correctly. Then it is on to the next task.

- We cover the three learning styles with hands-on, visual overhead, and the training software we provide as a free extra that has audio narration. We always provide training software courses for a refresher at a later date and for continuing education.

- As the instructor test students each step of the way, the 'final exam' we give, is actually to evaluate the instructor's effectiveness. We call it a quiz and it is administered to the students. If the students do well on the quiz, then the instructor passed the test. If they were weak on a particular task, the instructor goes over the task again.

- So in summary: Business Industrial Network defines "Training" as ... Hands-on while evaluating each step taught and providing additional learning material for continued self-education. We do not consider reading a book, listening to a presentation, etc., as "Training". We consider presentation format as learning or knowledge transfer.

Or if you prefer, email to training @ bin95.com, or call during normal business hours at 702-625-7715

For the individual seeking plc training, please see below.

| Use our highly interactive PLC training distance learning certificate courses, with no travel cost? Please see ... |

|

Automation Specialist Course Bundle

Automation Specialist Course Bundle