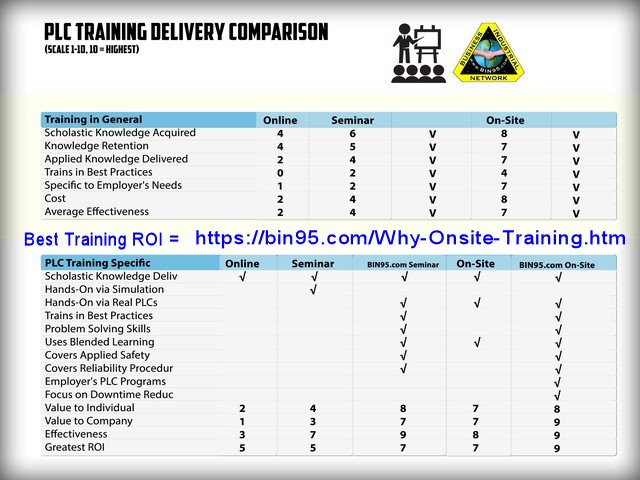

Why use onsite customized training?

Greater ROI, customized training and experience, personalized one-on-one training, and fewer travel expenses...

We teach best practices to reduce downtime.

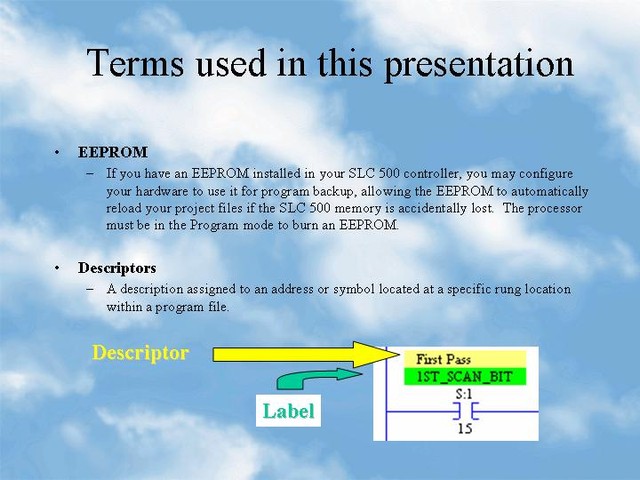

We emphasize documenting PLC programs.

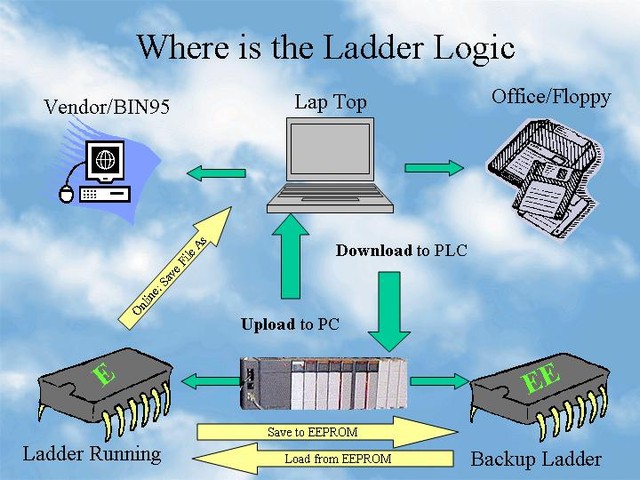

PLC program management and backups reduce downtime too.

We perform our PLC training at the customer's facility, customized training to each specific customer's need. Most customers have 3 to 6 employees in the class (5 days of training). This consists of hands-on training from day one in an uninterrupted classroom environment using a copy of the customer's PLC program used in their facility. We bring everything needed for training, employees need only show up ready to learn. Our blended learning approach uses real-world programs to ensure no employees are being left behind in contrast to others' training where the instructor follows a "canned" curriculum.

Our training method ensures employees receive a high-quality level of training that also matches their experience and their facility's needs.

.

Customers find this to give them the greatest return on their PLC training investment.

With the instructor's guidance, the employees receive real-world examples and experience with the actual equipment they will be working with on a day-to-day base. This also gives instructors the opportunity to advise the customer on their documentation, program backups, and recommend procedures to better ensure reliability and minimize downtime.

If requested, we will adjust the curriculum to promote any requirements made aware of with respect to your company's Standard Operating Practices.

Our customized training qualifies for most state reimbursement programs! |

We strongly recommend one person from each shift be trained in PLCs.

Most customers are utilizing the 3-6 employees per training session. With onsite PLC training, customers save the extra travel expenses it would otherwise cost to send multiple employees to a training facility located elsewhere.

Some of the key advantages to utilizing our training services compared to others are:

- We actually train each employee, not just present the information. The instructor roams the class insuring each employee can perform the task, as each task is taught, and this is why we limit the class size to 5 employees. If you have more than 6 employees, we recommend you schedule multiple classes of six or fewer so you continue to receive the maximum return on your training investment.

- We provide the option to work with one of your actual facility's PLC programs in the class, so employees are becoming more familiar with the equipment they will actually be working on.

- We stress and structure the knowledge delivered to result in your facility becoming less OEM dependant resulting in less downtime and greater savings as a result of our training. Employees learn valuable tips that most OEMs would not share with you.

- We focus on real-world topics and techniques that better allow your employees to work with PLCs in the safest and most reliable way. Most others just present the "how to", not the best way to perform a task safely, and also train employees in using good work habits.

- Unlike our competitors, we encourage employees to continue their education by providing additional learning material and fully licensed copies of both our software-based PAC and PLC trainers at no extra cost.

We hope you will consider letting us help you reduce downtime through more efficient troubleshooting skills, training and procedures.

Please contact us and we will assess your maintenance personnel needs.

Or if you prefer, or call during normal business hours at 702-625-7715