PLC Controller Failure Rate

- Home >

- articles >

- automation >

- plc controller failure rate

By Don Fitchett

It's not so much what the PLC MTBF (failure rate) is, it is more about what the causes are.

As typical with electronics and electrical devices, heat is relative to PLC Controller failure rates.

Generally speaking, one should assume a very low probability of failure for PLC controllers. For most of you who are looking for PLC controller failure rate estimates like MTBF statistics, the data is to be an end to a means. What you are ultimately looking for are answers to questions, like what parts and how many should you stock, what are the weak areas, how to make your equipment more reliable, is a PLC controller more reliable than another form of control, etc. Basically, the PLC controller has the life cycle of and is as reliable as military spec electronics. For marketing and liability reasons, it can be difficult to get PLC controller failure rate estimates from the PLC vendors, but you may convince each of them to point you to that estimated data.

Seeking out a PLC vendor's particular PLC MTBF estimate, and planning based on those numbers can be a wasteful effort. The vendor's PLC MTBF is a combination of all modules and all component MTBF. So the PLC MTBF numbers for a PLC controller as a whole will vary by unpredictable amounts given all the various possible module combinations and more importantly given all the variables introduced by the failure factors explained below. Your time would be better spent using the module type reliability list below, and estimate the MTBF for say an output module on one bottleneck machine while taking into consideration your specific failure factors listed below.

Example: Even with the highest risk module type, an electro-mechanical relay output module, and all failure factors optimized for reliability, the estimated MTBF, would be of little value. This is because relay failure should be estimated based on activation, not time. One machine may activate a relay on the output card once per hour, and the machine only runs 8 hours a day, 5 days a week. Another machine in the same facility, same output card may activate a relay 120 times per hour, and the machine runs 24/7. Yet both output cards would have the same MTBF provide by the vendor.

Because of the lack of recording PLC controller failure rates and causes by end-users, it is impossible to get real-world historical data that is not collected. The good news is, as a PLC training company independent of any single PLC vendor, we provide you the real-world information you are seeking from the data, in this article. We are able to do this as we have surveyed thousands of plants for over a decade, maintenance and engineers, every industry, around the world, as well as our own very experienced personnel.

While keeping in mind there are always exceptions to the rule, PLC controller failure probability will remain very low compared to any other equipment in your facility. PLC controller failure rates will be increased by the following factors (in order of most negative effect on failure rate)...

- Factor: Environment

- Factor: Brand/Model

- Factor: Electrical Design supporting PLC

- Factor: PLC Management

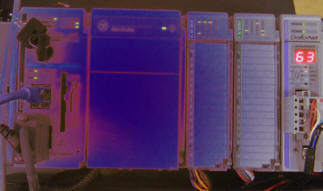

First of all, when considering and preparing for PLC controller failure, it should be on a modular level. As a PLC controller for the most part is solid-state, which in part is why it is so reliable with very low failure rates. So when considering failure rates, what parts to stock, reliability improvements, etc., you should consider each module type independently.

- PLC processor module

- PLC power supply

- PLC communication modules

- PLC input modules

- PLC output modules

The list of PLC module types just mentioned are in order of most reliable (the part with lowest failure rate listed first), with output modules being the most likely to fail. This reliability/failure order is based on the basic equipment failure rate we teach to our PLC training students. Which are ...

- Mechanical devices are more likely to fail than electrical,

- Electro-mechanical devices are more likely to fail then solid-state devices,

- High current devices are more likely to fail than low current devices.

While considering there are exceptions to every rule, PLC output modules are commonly electro-mechanical (relays) and/or higher current-sinking PLC modules. Therefore, they are the first thing you look at for stocking spares and doing reliability improvement analysis on, second is PLC input modules.

Now we'll explorer the failure factors for a PLC controller as a whole, the factors mentioned at the beginning of this article. The order starting with the most common PLC failure factor "Environment", then "Brand/model", then "Electrical Design supporting PLC", then followed by the one factor you have the most control over "PLC Management".

PLC Environment: If the electrical panel with a PLC controller in it gets exposed to extreme heat or cold, liquids, vibration, dust, etc., the PLC controller failure probability increases.

PLC Brand/Model: While a PLC, in general, has the lowest failure rate out of all automation control technologies, one brand may be more reliable than another brand. The various models of PLC controllers within any one vendor have a much greater reliability/failure distinction. For example a "soft" PLC installed on a standard consumer PC that cannot handle the rough industrial environment is almost sure to fail. Thus the reason you do not see hardly any of the 'soft' PLC models each PLC vendor offers, being used anywhere. As Dick Morley (the father of PLCs) reminded me in one of our phone conversations, "With increased functionality and complicity comes increased failure". To that point, a PAC model (advanced PLC) will have a higher failure rate than a PLC controller.

Electrical Design supporting PLC: Because the end-user of PLC controlled equipment commonly chooses the lowest bidder, the equipment designers (OEM) tend to cut corners in design so they can be the lowest bidder. A very common example of this is the combination of the OEM not putting line filters on the control side of the electrical panel's transformer secondary and not putting an EEPROM in PLC. Therefore, it is not uncommon during lightning storms and other power noise conditions, that a PLC controller will lose it's program and production goes down.

PLC Management: The best example of this PLC controller failure factor is not having any PLC management or policies in place at all. Also under this category come many failure reduction actions to implement for little or no cost, like electrical PMs (as cleaning electrical panel's cooling fan filter). Not having an up to date backup of the program in the PLC controller, not ensuring the only person working with PLC controllers, have had PLC/automation safety, reliability and best practices training, etc.. Most people working with PLCs today have only received scholastic and theory education, not training.

Do you have a question or comment?

Please contact us, we want to hear from you.

Related Training ...

5 Day onsite PLC training Course (Info above covered in this course)

PLC Troubleshooting Training Simulation software (Gain years of troubleshooting experience)

PLC Training Video Course (10 DVD Set w/ workbook)

True Down Time Costs Analysis - ROCE accounting [eBook]

Next Article ...

Business Article - Equipment failure and the cost of failure

True Downtime Cost - downtime tracking, OEE, root cause

Categories: plc controller, plc failure rate, plc controller failure, automation controller, equipment failure rate