Rotating Equipment Alignment Training

- Home >

- vocational-training >

- mechanical >

- rotating equipment alignment

rotating equipment alignment methods including motor shaft alignment.

This course covers many rotating equipment alignment methods and related information.

The above picture is demo of the alignment course.

Rotating Equipment Alignment Training Demo - Content

rotating equipment alignment methods training

ESBN: yy1-6798-6040-zb25

Description: (40 hrs)

The course on rotating equipment alignment trains in methods to align motor shafts. These are straightedge, rim face, reverse dial indicator, and laser alignments.

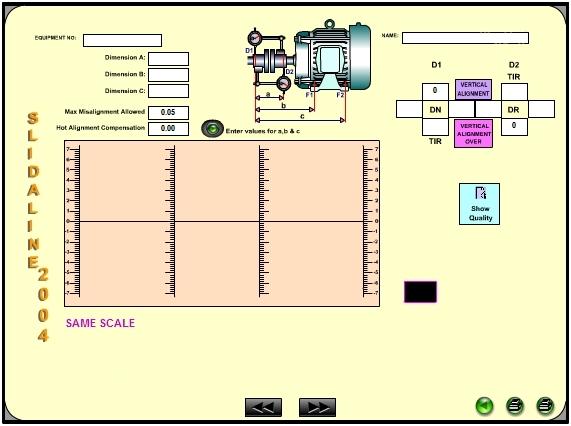

The course's heavy use of graphics and animation helps the learner with the alignment procedures. The procedure details the alignment of the reverse dial indicator (peripheral). The dial indicator method is also the basis of the laser alignment technique. The alignment training program has a tool, "SlideAline." SlideAline and a reverse dial indicator allow easy, effective alignment (coupling/shaft). The focus on misalignment's geometry via complex animations offers deep insight. It shows the learner how to perform the correct alignment procedure.

- The course covers alignment basics, accessories, and various methods.

- In-depth understanding of the reverse peripheral method.

- Latest techniques, like laser alignment.

- Extensive graphics, animations, skill tests, and certificate printouts.

- The course includes the alignment tool SlideAlign.

Who Can Benefit:

Untrained students and maintenance staff will find this training on rotating equipment alignment helpful. It will boost their knowledge and confidence in maintenance work. Those with prior training may find this program a good refresher. They may also learn important information outside of their original training.

Hardware Lock:

This course is also available using a "Hardware Lock" licensing method. Many users want to use the software on multiple computers. For example, they want to work with it on both their office and home computers. This Hardware Lock method allows users to install the software on as many computers as they like. They only need to enter the key on whichever computer they want to use the software. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

You can also ask us to embed your company logo in the training software for the hardware lock option.(Please note the URL of your company logo in the comments when ordering, or email your logo to us to use this feature.)

We will send an email confirming the order within 24 hours after purchase. If you ordered a downloadable version, check your email. It has the download link and activation code. We send a second email with tracking info if you ordered one of the shippable versions.

Download (1 Installation on 1 PC, Unlimited users, 1 User at a time.) $149

1 Hardware Lock (Unlimited Installations, Unlimited number of PCs, 1 User at a time.) $349

1 Network Hardware Lock (Network Installation, Unlimited number of PCs, 10 Users at a time.) $1049

1 Network Site License (Network Installation, Unlimited Simultaneous PCs and Users) $2100

Schools or companies needing a SCORM version of the above site license, please contact us and request a quote.

Alignment Course Table of Contents

- 1. Introduction - Rotating Equipment calling for 'good alignment'

- 2. Alignment Accessories and related topics

- Different types of Coupling

- Universal Clamping arrangements

- Dial gauge and Interpretation of Dial Gauge Readings

- 3. Alignment history and different Methods used for Alignment

- Straight Edge Alignment Method

- Rim and Face Alignment Method

- Reverse Dial Indicator Alignment Method (Reverse Peripheral) Introduction

- 4. Understanding the Geometry of Misalignment

- 5. The most practical method: Reverse Peripheral Alignment Method

- 6. Laser techniques used for Alignment

- 7. Preconditions to achieve and retain a Good Alignment

- Soft Foot

- Pipe Strain

- Thermal Growth

- Sag of Alignment Clamps

- Dial Gauge Errors

- 8. Skill Tests with evaluation

- 9. Alignment tool - SlidALine: Simulated training and Maintenance Tool

- SlidALine

- SlidALine Help

Related Products:

Gas and Air Compressor Training

Hydraulics Training Certificate Course

Centrifugal Pumps and Troubleshooting Guide

Industrial Hydraulic Systems and Circuits

Hazardous Area Instrumentation Training

Handbook for Machining Equipment Maintenance

Article: Rotating Machinery Testing

Please click Contact BIN95 to contact us with your questions and comments.