Allen Bradley PLC Technician Training

- Home >

- vocational-training >

- plc-training >

- allen-bradley >

- plc technician

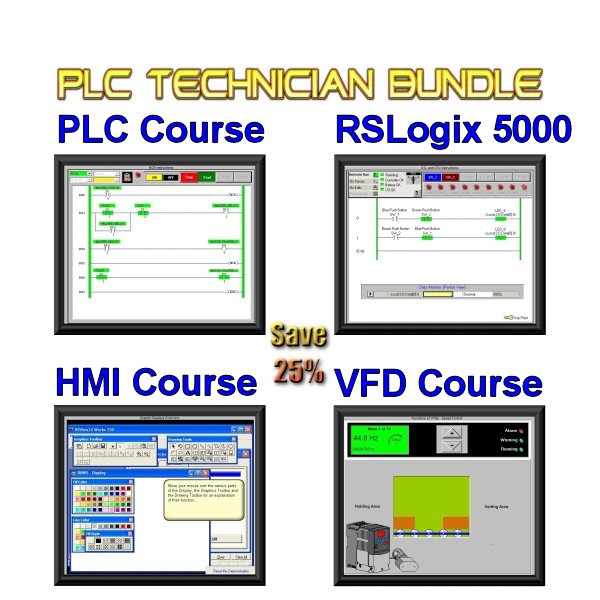

The PLC Technician Training Software Bundle.

This bundle of certificate courses includes the following 4 Allen Bradley PLC software certificate course titles. Of specific interest to PLC technicians as well as others. This bundle includes the PLC, PAC, HMI, and VFD trainer courses. Great for students interested in becoming a PLC Technician and existing PLC techs wanting to get familiar with the Allen Bradley PLC software brand.

These are not PowerPoint courses like online courses. These are automation courses built with training simulations like the Allen Bradley PLC Trainer course software. This delivery platform allows the courses to be highly interactive and deliver hands-on experience with built-in simulations, as shown on each course detail page below. This trainer software also allows many other features, like printing certificates, bookmarking, narration, glossary, offline access, no expiration, and more. With this PLC Technician Training Bundle of certificate courses, the learner starts with the Allen Bradley PLC software trainer, then VFD, next the PAC, and ends with HMI.

Four Allen Bradley PLC Technician Training Courses

Save 25%! by bundling

Allen Bradley PLC Training Trainers - The PLC Technician Bundle (95 hours total)

Prod #: KT-098B-PLCTech-Bundle

Allen Bradley PLC Software Trainer Courses:

- VFD Training Certificate Course

- PLC Training Certificate Course

- RSLogix 5000 Training Certificate Course

- HMI Training Certificate Course

- Every course has many interactive screens.

- Each course has a final exam.

- Each course has a printable laboratory manual.

- Each course prints a certificate of completion.

Tap each certificate course software title below to see details, screenshots, and videos of the course software being used.

Included PLC Technician Training Courses:

The automation training courses listed below are in the recommended course completion order. Starting with the motor controls, followed by VFD, then on to the PLC/PAC courses, and wrapping it up with the HMI and industrial networking courses.

Rockwell PLC Training Course

PLC Trainer Training Course

The PLC Training Course has the look and feel of Rockwell Automation software. This course covers PLC basics, data manipulation, and shift registers. There are interactive simulations for most topics. Even the Sequencers and analog sections have simulators. As with all the courses here, it ends with a section on troubleshooting. - 30hrs

Plus, get even more hands-on experience with the PAC/PLC simulator incuded in this bundle!

VFD Wiring Diagrams to Troubleshooting Covered.

VFD Trainer Training Course

This VFD Training Course starts with the fundamental operation of Variable Frequency Drives (VFD). Installation, programming, and troubleshooting are then covered. There are also sections on AC motors, start-ups, and soft starters. All in a proven structured curriculum to ensure the best understanding and retention. - 15hrs

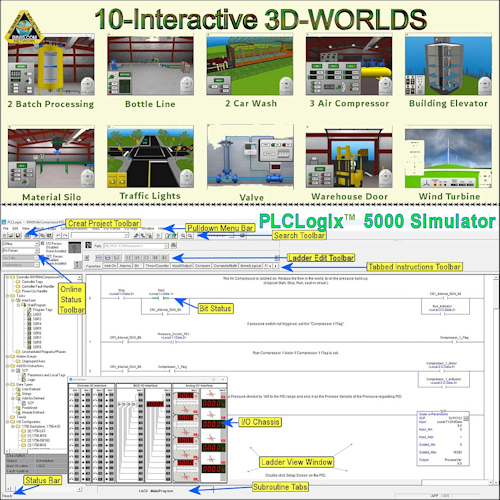

1 of 63 Rockwell Automation's RSLogix 5000 Simulations

RSLogix 5000 Training Course + SIM

This RSLogix 5000 Training Course introduces the PAC hardware and software. Allen Bradley PAC hardware is the ControlLogix. The associated software is the Rockwell RSLogix 5000. Learn the fundamentals of Rockwell Automation's RSLogix 5000 PAC programming software. Become more familiar with the Programmable Automation Controller (PAC) called the Controllogix. - 30hrs

Plus, get even more hands-on experience with the PAC/PLC simulator incuded in this bundle!

RSLogix 5000 Simulator

RSLogix 5000 Training Simulator

We include the PLCLogix 5000 simulator in this bundle so learners can get additional hands-on experience, to suppliment the PLC and PAC courses. (Currently at no extra cost celebrating our 30th Aniversary.)

The simulator has 10 interactive 3D worlds, 80 simulated PLC RSLogix 5000® instructions, and 200+ pre-written programming examples.

HMI Training Simulating Rockwell Automation's RSView.

HMI Trainer Training Course

This HMI Training Course software uses Rockwell's RSView32 platform as an example. The course includes details about RSLinx communications, DDE Excel, RSView graphics, and more. We chose the original RSView32 version instead of FactoryTalk to teach HMI. This original version makes it easier for the beginner to learn the fundamentals of HMI. This is also an excellent course for instrumentation technicians. IT engineers new to industrial HMI will find it a great introduction. - 20hrs

Even setting up communication and getting online is simulated in the Allen Bradley trainer course software!

Testimonial:

Chuck Pheiffer - Maintenance Mechanic

"Many of the guys that I work with have been using and talking about your PLC Trainer bundle. I finally ordered a copy and want to let you know that this is exactly what I have been needing. My understanding of the instruction set for our 5/04 processors is so much better now. Now when I am troubleshooting a process, I can look at the logic in monitor mode and actually understand what is supposed to happen. This made my job sooooo much easier."

Foundational PLC Technician training for understanding and working with Allen Bradley automation systems.

Within 24 hours of placing the order, we will email you the download.

Order a Single Student License above. Or order unlimited students/installs per physical site with the Site License.

For unlimited physical site licenses (locations), please Request a Quote for the Enterprise License.

Features of the PLC Technician Training Courses in this bundle:

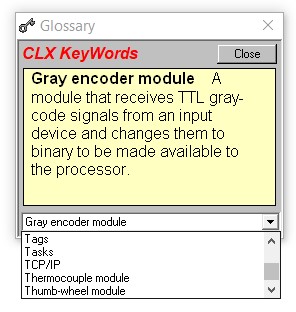

Each course has a built-in glossary of terms either integral or as a printable PDF. Below is a screenshot of the RSLogix 5000 glossary of terms as one example.

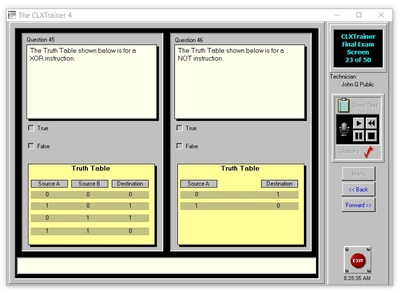

Each course has audio narration for every screen, text transcripts, and the ability to bookmark pages. Each course has an interactive "self-scoring" final exam and the student will be presented with the option to print a certificate of completion upon scoring 85% or better. Below are examples.

School and Company Multiple User Licenses:

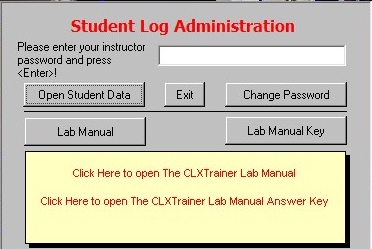

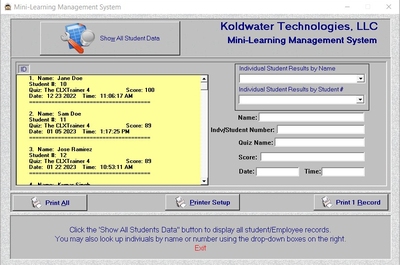

A mini-LMS built into the Site and Enterprise licensed versions of this course software.

With the site licenses, even if the certificate is not printed on test completion, the score and student's name are still saved in the "student log file", accessible by Site and Enterprise license holders. Additionally, when the quiz is scored, the student name and final score are appended to a comma-delimited text file that may be imported into a database or spreadsheet application.... making the site license purchasing option perfect for Technical Schools, Community Colleges, Universities, Apprenticeship Programs, and company training departments.

Each course includes its own printable PDF Laboratory Manual. The manual consists of optional questions and one or more exercises for each of the course sections. Some exercises will require the instructor to make software and/or hardware available to students/employees. No content in these lab manuals is required for students/employees to take and pass this course. Answer key to lab manual questions and exercises is also provided to instructors with a Site License.

Because these courses start from a beginner level, and they use interactive simulations to make learning easier, these courses will also work for capable students without previous experience in the field. But it is advised that they follow the recommended learning path indicated by the course order listed above, and at the bottom of any course's detail page.

The PLC Trainer Lab Manuals are 30-179 pages and are a great instructor aid.

Return to Purchase Area

All trademarks and trade names are property of their respective owners. We are in no way affiliated with Allen Bradley®/Rockwell Automation®.