Employee PLC Programming Training Courses

- Home >

- vocational-training >

- plc-training >

- onsite >

- plc training

(We Specialize in Rockwell Automation PLC Training.)

Business Industrial Network provides on-site, customized training for your staff. It covers both PLC (Programmable Logic Controller) and PAC (Programmable Automation Controller) programming. If you want, we will use your programs in class. This will help your team get more familiar with the equipment. This customization is yet another way we respond to our customers' needs.

Our survey of over 300 companies and corporations reveals two well-known facts.

1. The most unplanned downtime occurs during the off shifts.

2. Many companies do not have PLC-trained maintenance technicians on the off shifts.

Our studies on the true cost of downtime show that PLC training for off-shift employees yields a high ROI. Our custom certificate program also helps those with prior PLC programming training.

Maintenance technicians have two good reasons to train more with Business Industrial Network.

1. "I took an OEM course a few years back, but it went too fast and taught topics I have never used."

2. "When you hardly ever have to troubleshoot PLC control systems, you forget that classroom stuff."

We ensure that those two do not occur with our training. We also provide both PLC and PAC training software courses free with on-site training. The course software and PLC manuals let your team learn more anytime. They can also take a refresher.

The PLC Training Solution:

Our customized PAC & PLC programming training for your maintenance department

(What sets us apart from your other PLC training options.)

- We review and use the actual PAC (RSLogix 5000) & PLC programs (RSLogix 500) you use in your facility.

- We customize the topics and material to match your maintenance staff's needs.

- We train each employee, not just presenting the information. The instructor ensures each employee can perform each task as taught.

- We provide knowledge to reduce your OEM dependence. Our training will cut downtime and boost savings. Employees learn valuable tips that some OEMs may not think to share with you.

- We focus on real-world topics and techniques. We train your employees to operate PLCs with enhanced safety and stability. Most others teach 'how to' do things, not safety, good work habits, and the best way to do a task.

- We deliver the training to your facility, or you can book a local conference room.

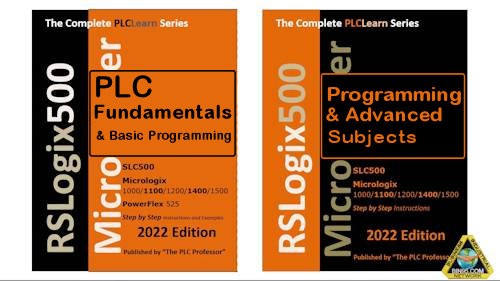

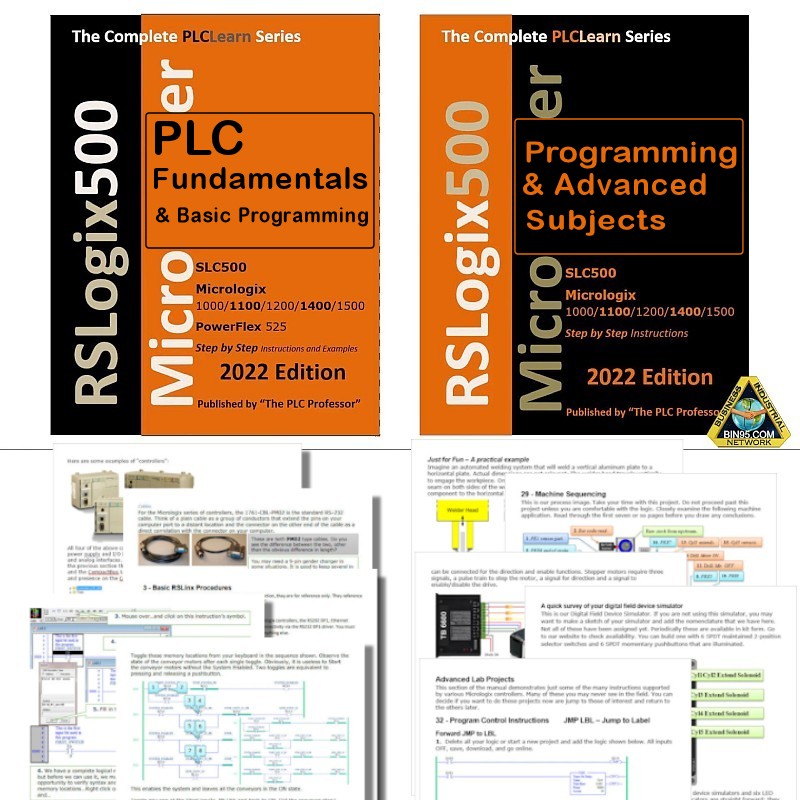

- We supplement hands-on training with materials for attendees. Yes, employees receive training manuals and workbooks. They also receive PLC simulation software and our PLC/PAC course software. They can use these to refresh and learn more at any time.

- We wrap up the world-class training with a test to assess its effectiveness.

Learning Objectives:

Attendees master safe and reliable PLC operation using proven methods. After this course, they will be able to upload and download programs. They will also be able to modify existing programs. Employees will also learn how to do minor PLC programming and troubleshoot using a PLC. They will do this while minimizing downtime.

Two on-site automation training types to choose from:

This class covers the basics and more. It includes topics and instructions usually not taught in school. This can be a class that is quicker-paced depending on attendees' experience. These classes use Allen Bradley's MicroLogix 1400 training stations. There are two attendees per training station. Maintenance and engineers learn the basics with Rockwell/Allen Bradley RSLogix 500 brand. Designed to expand their knowledge as much as possible in 40 hours. The attendees receive a course manual and workbook for reference. (PLC Certificate Program Curriculum PDF)

PAC Training: This 40-hour class covers the PAC basics using Studio 5000. It uses Rockwell's RSLogix 5000 and Allen-Bradley's CompactLogix training stations. There are two attendees per training station. Maintenance staff and engineers learn the basics of PAC software and hardware. The attendees receive a course manual and workbook for reference. (PAC Training Curriculum PDF)

Note: Those wanting to learn RSLogix 5000 PAC should start with the RSLogix 500 training class first.

Featured Instructor: Tim Gates ...

"The PLC Professor"

Book Tim to deliver the PLC technician certificate program to your employees or faculty soon, as he will retire in a couple of years.

A trusted automation training provider since 1995.

We adapt for customer's training room.

RSLogix 5000 training too.

We are the Allen Bradley PLC trainer near you.

Training AND Evaluation.

Training at your facilities.

Our PLC troubleshooting training reduces downtime.

Why on-site customized PLC training?

We train your team to troubleshoot and maintain your facility's equipment. We train beginners on the basics. We also offer advanced training for your techs on new assets and technologies.

We recommend that at least one person on each shift be competent in the following areas.

Safety.

Basic use of your RSLogix software.

Understanding ladder logic usage.

Sound practices in file management, downloading, and EPROM/flash management.

Set up PC-to-PLC communication.

Setup/troubleshooting of RSLinx drivers.

View the program online and offline.

Troubleshooting actual problems.

Familiar with PLC programming conventions used in your equipment.

Understanding best practices in PLC programming systems.

How to review new asset automation before purchasing.

Understand the importance of working towards being less OEM-dependent.

This certificate program also qualifies under the Workforce Investment Act and state reimbursement programs. Your company could get reimbursed for some or all of the training fees if they pursue that. We are in the Federal CCR database. This is for any government employees interested in this course.

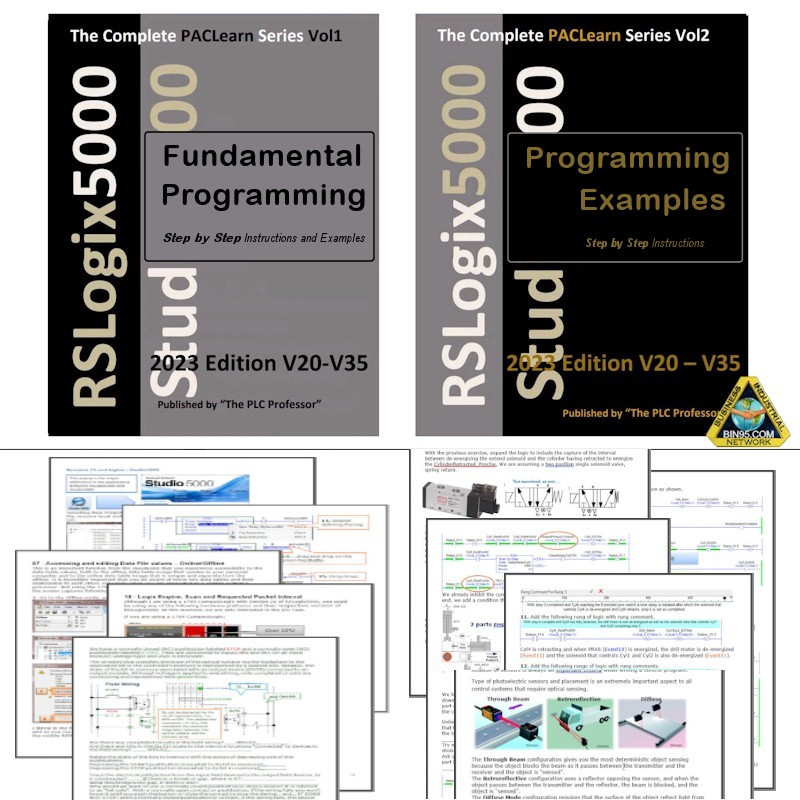

Our PLC training is hands-on, using our PLC trainers. We also provide printed manuals and workbooks with many practical PLC programming exercises.

PLC programming manual and advance topic workbook.

Hands-on with PAC and PLC Trainers

PAC programming manual and programming workbook.

Your choice:

CCW - RSLogix 500 PLC Training

(SLC 500, Micrologix, and Micro800 hardware.)RSLogix 5000 PLC [PAC] Training

(ControlLogix and CompactLogix hardware.Or, both 1 and 2 above.

Please check the Free online Industrial Training Skills Assessment Tool. It will show if you or your maintenance staff need this training. Take the series of PLC assessments provided there. Our extra training not found in textbooks or manuals may surprise you. Our on-site training fees are the lowest in the industry. Our cost-effective, value-added principles form the basis for them: "The Best for Less."

Customer comments ...

Sabrina Taraboletti, a Chief Engineer at NOAA.gov, wrote a good, full-page course review to her Training Director. It is too large to place on this web page, but upon request, we would be happy to share the full review with you. Below are some valuable insights from her review of the class...

"Don uses the RXLogix 500 series. It's easier for beginners to understand and troubleshoot. You must know the basics of the system. Then, you can learn the more complex features of the RXLogix 5000 System. ...Analogy: you must learn how to run Windows 7 PC edition before tackling Windows 7 Server edition. ... My 3rd assistant engineer had done some PLC work at school and on her cadet midshipman vessels. She also felt this was an excellent course. It was a good starting place for those like her with some PLC experience. ... I am not sure about the other FSVs, but the Shimada has a Toughbook PC with RSLogix 5000 loaded on it. I brought that with me to the class. I would show up early. Don would help me with the 500 and 5000 series machines. I want to know their differences and similarities. This was a great help and I came back with a better working knowledge of that computer and how to use it. You get a certificate, a USB drive, and an Allen Bradley Micrologix PLC. It connects switches and lights to it. This is after you finish the class. You can practice programming with them at home. This thing is not a toy; it distinguishes BIN folks from others. ... In conclusion, this course would benefit all engineers, EETs, and ETs in the Fleet, not just those who work on FSVs. We will control the new ships added to NOAA with these devices. Everyone should have at least a basic understanding of how these things work. Don is eager to do on-site training. this would be an excellent course to hold during winter in port at the MOC locations."

John Marques (Smith & Nephew ASD) "I recently took Don's PLC training when my company offered it. I've spent twenty years focusing on maintenance, barely scratching the surface of PLCs. I could troubleshoot most PLC-driven things by watching the outputs. But that only gets you so far. His course was easy to understand and helped me greatly regarding PLC issues. I would recommend anyone in maintenance take this course if the opportunity arises! Even if you don't get into programming, it's a good troubleshooting tool to have."

Walter J Rivers (Georgia Pacific) "Jim was very patient. He helped us, explaining at every step."

Elaine Vavra, a Southeast Community College instructor, said, "It's one of the best hands-on classes I've attended. The hands-on work really helped my limited experience with PLCs."

Jim (Maintenance Manager) "This training is not like the vendor training we have received before where they try to sell you their hardware. We where getting hands-on training after the first hour and advice that only an experienced end-user would offer. A great supplement to our tech school training. Thanks"

Jeff Rodriguez (Maintenance Superintendent at Fall River Foundry) "The PLC programming training I received from this organization was the best I have sat through in many years. Detailed and real on hands training and troubleshooting knowledge. I have used this organization 4 times now and it has been a big hit from all the maintenance techs I sent through. Great job from the trainer. "

Will Inglis (SB Electronics) "Don's teaching methods for the PLC Troubleshooting class were very impressive. He knew when to slow down to help the confused. And, when to speed up if everyone else was following. The class is highly recommended, and Don makes it a great experience for everyone."

Timothy Wilson (Technician at Corning Life Sciences) "Don's RS Logix course was very informative. He was attentive to the standards. The class was very involved. Don worked hard to ensure everyone kept up and understood the work. I would recommend Don to anyone for his technical knowledge and the patience to get the job done."

Mark Mason (OCI Chemical DCS Admin) said, "The instructor knew the materials well. He provided useful, real-life examples."

We thank our corporate customers for training their employees. We hope they enjoy the yearly ROI from reduced downtime and improved reliability.

Also, see "Which is the best PLC technician training and certification?" for further help in deciding the best training delivery method for you.

Please see our Contact BIN95 form to submit your questions and comments.

Or, if you prefer, email training @ bin95.com, or call during normal business hours at 702-625-7715

For the individual seeking Automation training, please see below.

| Use our interactive automation distance learning courses, with no travel cost. Please see ... |

This bundle is popular with electrical training institutes, like IBEW locals. They use it to transition commercial electricians to industrial electrical contracting. This bundle includes training on PLCs, PACs, HMIs, VFDs, motors, controls, and troubleshooting, as well as DeviceNet. |

Automation Specialist Course Bundle

Automation Specialist Course Bundle