Automated Predictive Maintenance (APdM)

- Home >

- articles >

- electrical >

- engineering >

- automated predictive maintenance

Automated Phase Angle Diagnostics of Rotating Equipment

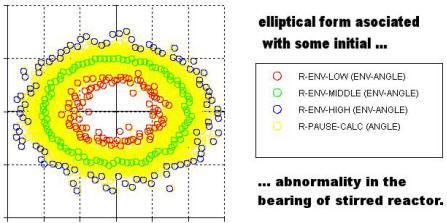

The fractal above has an elliptical form. This form is associated with some initial abnormality in the bearing of stirred reactor.

Phase Angle Diagnostic results in earlier detection than Vibration Diagnostics.

Phase angle diagnostics is quite sensitive. Mitsui Chemical, Iwakuni, Japan, had performed a testing of the sensitivity of continuous monitoring by the Phase Angle Technology comparing the Vibration inspections provided every four hours.

"he test had shown that Phase Angle Diagnostics reveals

Fan misbalance much earlier than vibration measurements. "

Itused to be the question of should a maintenance department invest in the science of Predictive Maintenance (PdM), a Condition Based Maintenance (CBM) program and how much. But now it is pretty widely known the answer is yes to investing into PdM. Although today, you will still find a few with the 'Run Until Breakdown' asset management philosophy. Now days the question is how to detect earlier, how to automate PdM?

Predictiv Systems Engineering Ltd (PSE) developed a proprietary method of motor current analysis that detects mechanical failures in machines driven by induction motors and generators (PredictiveOnLine™ Cloud system). It’s based on the on-line detection of the phase angle of the induction machine which is proportional to motor torque and a proprietary algorithm for Phase Angle analysis. Analyzing the phase angle—rather than current—avoids the influence of a non-stable power voltage or frequency that usually makes it difficult to detect minor disturbances in motor current signatures. The Phase Angle readings reflect the small mechanical disturbances or fluctuations in a machine driven by an induction motor. Phase Angle Diagnostics uses an induction motor as a diagnostic tool for predicting/recognizing failures not only in the induction motor itself, but also in the rotating equipment driven by that motor.

Phase Angle Diagnostics Basics:

The Phase Angle in the induction motor or generator means a value of delay of a Current Sine from a Voltage Sine. This delay is illustrated by segment I(t) and V(t), below...

Phase angle signals are proportional to values of electrical motor torque. The torque could be considered as a sum of two components: a mean value which is proportional to the load and another one caused by the mechanical events in the machine driven by an electrical motor, friction losses in bearings, load fluctuations, events in the motor itself, etc. These fluctuations are relatively small but can be recognized by signal processing such as Spectral Analysis and other.

Phase Angle diagnostics reveals mechanical failures in the rotating equipment, for example ...

- A fan motor with loose foundation

- Low belt tension

- Angular misalignment

- Over or under lubrication

- Abnormality in the bearing before vibration analysis would indicate

- Unstable movement of the shaft inside bearings

∆ Phase range signals typically are very stable, even over several years. So a change clearly shows potential problems. ∆

To view 11 page white paper with more details, graphs and examples, click phase-angle-diagnostics.pdf

Paul Klein -Predictive Systems Engineering Ltd (PSE)

|