- Home >

- articles >

- maintenance-management >

- big data how to calculate roi

Industrial Big Data, How to Calculate ROI for Downtime with TDC

Just as True Downtime Cost ® (TDC) justifies Lean projects, it also improves the accuracy of big data analytics.

- Downtime

- Time during which equipment or system is unavailable for use. ⇓ MORE ⇓

- DOWNTIME

LEAN acronym for 8 forms of waste.

Defects, Overproduction, Waiting, Not utilizing talent, Travel, Inventory, Motion, Excess processing- Down Time

- Time off work to relax.

Downtime Definition

This article introduces two elements organizations must add to most big data efforts. They will help end users achieve their ROI goals. Learn to calculate ROI for industrial big data projects. Use an accurate downtime costing system, TDC, to find the true cost savings.

We'll get to the two missing big data elements in a bit. But first, it may help to give you a little historical context for better understanding.

We founded and introduced the True Downtime Cost ® (TDC) to the industry in 1995. We ran into the main barrier, realized ROI, or should I say, perceived ROI. Back then, few machines and systems connected to each other. It was expensive to implement it on every machine and system. Also, getting the data to a single point to analyze True Downtime Cost was costly. Nowadays, the cost is much lower. Of course, they arrived at a compromised solution.

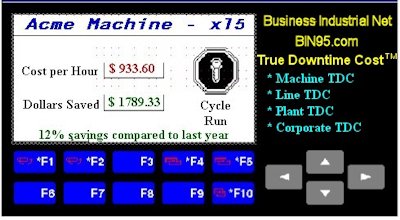

Critical machines and systems, like bottlenecks, would have an HMI or other display. It would show the current OEE and TDC values to operators and managers. This communication was to effect action and change to improve those values. So, it must show a good ROI in real time. It should also display dollar amounts on the screen. Money is a great motivator. Management kept the approach simple and relevant to its end users. Later, I share an excerpt from the "action plan" chapter of "True Downtime Cost - 2nd edition" as an example.

A decade later, networking machine PLCs and systems were common in the industry. Of course, Fortune 500 companies and other world-class organizations led the way. TDC's focus and popularity grew in the industrial sector. They used it as a cost-justification tool to better reflect true ROI. TDC is popular for boosting focus and effectiveness. It also helps justify Lean Six Sigma initiatives.

Yet, downtime costs big data initiatives needed to become mainstream. A second barrier, the vast amount of data. Data overload was still blocking it. Both end users and vendors wanted to add code. It would merge and analyze the TDC data for strategic analytics. But, they believed it needed to be more manageable. Even those who collected the big data did not see the true ROI. They failed to analyze and act on the data. CMMS was a prime example of that. In the past, they used maintenance management systems for work order management only.

Fast forward to today…

Today, you see millions of ads for big data and the 'cloud' (storing sensitive data and apps off-site via the internet). Also, the "IIoT" (again, sending your sensitive data over the internet). Ironically, the marketing industry knows the ROI of big data analytics. So do other sectors, like IT.

IT departments went further to justify their Big Data ROI. They used a knock-off of TDC's downtime cost, called 'Real Downtime Cost.' But, the industrial sectors still lag behind them, as is typical. No offense to the industrial sectors, as the government lags way further behind them. Also, with possible harm to people or machines, the industrial sector has more risk. It should advance with caution.

2 Barriers to Industrial Big Data:

- Realizing the ROI.

- Acting on the big data collected.

The most significant data issue today is not acting on the data collected. The same problem existed at the beginning of this long story. The paradox is that industrial companies and vendors must act on the data to realize the total ROI. Yet, they don't act on the data or start big data analytics projects. Because they need to see the true value of doing so. With the Lean initiative, the glue that binds the two is TDC.

Without accounting for True Downtime Cost®, they might perceive an ROI of 10-30%. If they apply the TDC cost of downtime metrics, they may learn that the actual figure exceeds 300%. As said before, money is the motivator. When the decision-makers see the actual value, they are more likely to act on the data. That action boosts their ROI, flipping the paradox. It drives constant improvement.

Side Note: There are similar scenarios and barriers on the macro level. Take CMMS software, for example. Today, CMMS software has excellent data analysis and reporting capabilities. But, those CMMS that don't apply TDC cost downtime metrics. For those that do, the end users still need to use and act on those features. Not knowing the total ROI, end users use CMMS only as record-keeping software. Worse, some don't use it at all. Without TDC, the motivator is missing... $$.

Big Data Action Plan:

Below is an excerpt from chapter 10, "Action Plan" of "True Downtime Cost - 2nd edition". It will give you some idea of how to start from the TDC perspective. You can get the book at the link above to learn the True Downtime Costing system TDC, how to define the cost of downtime for better business continuity and much more.

The True Downtime Cost Action Plan:

Overview of the action plan:

When introducing TDC to an organization, it's vital to get buy-in from both senior management and the shop floor workers. You must create a detailed plan to gain support from both. You must give each group the necessary information to support the TDC initiative. We need a plan and timeline. They must show the project's steps, resources, and costs. All parties must understand it.

Steps along the way:

Top-down:

For change to succeed, you must start from the top down. Start by asking your plant manager or corporate manager to review a copy of this book. Tell the manager you want to form a team. It will create an action plan to fit your facility's particular situation. Also, mention you would like the manager's input and welcome their involvement.

Select a team:

If you are an individual company, select a team size that suits your situation. World-class establishments include at least operators, maintenance, and management.

If you are a corporation using this plan, you need "a reasonable sample" of employees from your subordinate companies. It would help if you started your program and team building with one of your companies as a test.

Before a corporate-wide rollout, have a corporate team analyze the TDC implementation process. Use the results to refine the standard operating procedure. You would then apply the new plan to all companies in your corporation.

Set a goal:

The team's first assignment is to set the right goal for your company. Our advice is, "It is better to have a goal that is too high than one that is too low." Include strong financial methods of measuring success as a goal.

Using this TDC method to track monetary value closely sets you up for success. For example, if your goal was to review your two most costly lines and automate True Downtime Cost for them. You should see the displayed total cost of downtime drop, and the equipment will be down for less time. You would see a TDC display indicating a real saving to report. With goals in place, you can develop a roadmap to profit from TDC knowledge.

Develop a plan:

Next, you need to create a plan to reach your goal. As with any solid plan, it needs a timeline and allowance for contingencies. Also, remember to "plan to plan." Set time to check progress, fix issues, and update the plan. Whatever level you choose, your project will be in two parts. The first is the TDC implementation plan, and the second is the TDC utilization plan. Both are equally important to your overall success.

Below is a recommended plan template for minimum implementation and utilization. It includes a worked example plan. You can start small. Let success drive better performance in your facility.

- Goal

- Area of implementation

- Method of implementation

- Time to be completed

- Define technical steps and targets.

- Evaluate the area of implementation defined in the goal.

- Determine steps

- Place steps in the timeline template

- Apply methods of implementation following the timeline.

- Determine roles and resources.

- Request what needs to be done for the different groups, departments, or individuals.

- Also, brainstorm ways your organization can benefit from the TDC knowledge gained by reaching your implementation plan.

- After the TDC plan succeeds, record its benchmark baseline. Then, move on to the TDC utilization plan below.

- Implement your reaction plan based on the new TDC tools that are available.

- The plan may be as simple as managers making better decisions.

- Every week or month, survey users and report on the value gained by the new TDC knowledge.

- After 3, 6, or 12 months, interview all to report on how much the TDC knowledge has saved your company.

- Make this known to everyone from the top down.

After the above, Chapter 10 of the book presents a detailed example plan. Then, Chapter 10 covers the following areas.

Implementing Automated Data Collection

Motivating Management

Motivating Employees

Utilizing TDC in Daily Decisions

Then, it's on to chapter 11. You can read all the chapters and sections by downloading the book at True Downtime Cost - 2nd edition.

Understanding Industrial Big Data: How It Differs from Others

In today's digital age, "big data" is often used to describe vast amounts of information. But, big data analytics has a unique significance for industrial applications. Below we will explore how industrial big data differs from other types. It's crucial in shaping the future.

What is Industrial Big Data?

Industrial big data is about using vast amounts of data from an industrial setting. It involves collecting and analyzing that data. Unlike other big data, which may focus on consumers, industrial data is about machines and processes. It is not about website analytics. It includes real-time monitoring, sensor data, machine logs, maintenance records, and production metrics. This is to optimize efficiency and support decision-making.

Volume and Velocity:

Industrial data has a unique volume and speed. It generates more than other data sources. Many sensors and devices in factories and power plants collect data at high speeds. They do this continuously. This flood of information lets companies monitor metrics in real-time. They can quickly detect issues or bottlenecks. Quickly processing and analyzing this huge amount of data gives industrial firms an edge. It boosts productivity and ensures smooth operations.

Variety and Complexity:

Another distinguishing factor of industrial data lies in its variety and complexity. Unlike traditional consumer big data, industrial data includes many data types. It uses structured info, like customer preferences and purchase history. Industrial data includes unstructured or semi-structured data from various sources. This includes machine logs, IIoT, sensors, PLCs, HMIs, SCADA, and maintenance reports. We must analyze a diverse array of data. It is complex. But we need insights from it to improve operations.

Value and Impact:

Industrial big data analytics is very valuable. It has a significant impact on business operations. By harnessing this data, companies can find patterns and trends. They can also spot anomalies that were hard to detect before. Predictive analytics aim to foresee equipment failures. They reduce downtime and optimize maintenance schedules. Also, it can improve resource allocation, reduce downtime, and boost quality control. Industrial big data can transform industries. It can boost efficiency, productivity, and profits.

Big data in manufacturing:

Big data in manufacturing has changed production. It provides insights into efficiencies and areas for improvement. For instance, companies can use predictive analytics to track machines in real time. That enables manufacturers to address maintenance needs before they become critical. This approach reduces downtime. It fits the True Downtime Cost® (TDC) framework. It illustrates the costs of inefficient operations with greater clarity.

Big data and machine learning work well together. They support continuous improvement efforts. So, companies can better justify investments in tech and process upgrades. Using these innovations, manufacturers can boost their ROI. They can also create a data-driven decision-making culture that aligns with the TDC method’s goals.

The future of industrial big data:

The future of industrial big data is an exciting realm where the power of data meets the real world. Mining data from the industrial process and using sensor information can provide many insights and opportunities. Big data links intelligent manufacturing and the Industrial Internet of Things (IIoT).

Big data serves as the crucial link between these two transformative technologies. It lets us collect, analyze, and interpret vast amounts of data from industrial processes. Using this info to calculate TDC, we can optimize operations. This will boost efficiency and drive innovation in manufacturing.

Using industrial data, businesses can understand their processes better. They can find patterns and anomalies. This allows for informed, real-time decisions. From predictive maintenance to quality control, the applications are endless.

The Bottom Line:

Incorporate True Downtime Cost® metrics into your big data, analyze big data for strategy analytics, and most importantly... ACT on insight gained.

Related Learning Path:

We recommend ...

1st HMI Basics

2nd PLC Troubleshooting & SCADA

3rd OPC SCADA

TDC - "True Downtime Cost®" - Is a registered trademark of Business Industrial Network (BIN95.com)

© Business Industrial Network and https://bin95.com, Copyright © 2018 - 2025. Unauthorized use and/or duplication of this material without express and written permission from this site’s author and/or owner is strictly prohibited. Excerpts and links may be used, provided full and clear credit is given to Business Industrial Network and https://bin95.com with appropriate and specific direction to the original content.

All trademarks and trade names are the property of their respective owners.