- Home >

- articles >

- mechanical >

- industrial laser cleaning

Industrial Laser Cleaning

A Smarter Alternative to Chemical and Abrasive Surface Preparation

Introduction

Industrial laser cleaning is a modern surface preparation method that uses focused laser energy to remove contaminants without harming the underlying material. For decades, manufacturers relied on chemical solvents and abrasive blasting to prepare surfaces, even though those methods generate hazardous waste, consume large volumes of materials, and expose workers to health risks. As environmental regulations tighten and production efficiency becomes a competitive advantage, surface preparation is being re-evaluated across industries. Laser cleaning has emerged as a practical alternative because it offers precision, repeatability, and dramatically lower environmental impact. In this guide, you will learn what industrial laser cleaning is, how it works, how it compares to traditional methods, and how to determine whether it is a good fit for your operation.

What Is Industrial Laser Cleaning?

Industrial laser cleaning is a non-contact surface treatment process that removes unwanted layers by applying controlled laser energy to a target surface. The laser energy is absorbed by contaminants such as rust, paint, oxides, oils, or coatings, causing them to vaporize or detach, while the base material reflects or dissipates the energy. This process differs from chemical and abrasive methods because it does not rely on solvents, acids, or mechanical force. Industrial laser cleaning is used in manufacturing, maintenance, restoration, and surface preparation applications where material integrity and cleanliness are critical. Because laser parameters can be precisely adjusted, operators can remove specific layers without altering surface geometry, tolerances, or metallurgical properties.

How Does Industrial Laser Cleaning Work?

Industrial laser cleaning works by directing high-energy laser pulses onto a contaminated surface, where unwanted materials absorb the energy more efficiently than the substrate. This energy absorption causes rapid heating and micro-ablation, breaking the bond between the contaminant and the base material. The process is usable across metals, composites, and selected polymers, making it suitable for both production lines and maintenance environments. Laser-material interaction, selective absorption, and thermal expansion are the fundamental physical principles behind this technology. Unlike abrasive blasting, the laser does not physically impact the surface, which allows cleaning without erosion or dimensional change.

What Are the Main Stages of the Laser Cleaning Process?

Industrial laser cleaning follows a structured sequence that ensures accuracy and repeatability. There are five main stages involved in the laser cleaning process.

- Surface assessment and contamination identification, where material type and contaminant thickness are evaluated

- Parameter setup and calibration, where laser power, pulse frequency, and scan speed are configured

- Laser emission and ablation, where contaminants are selectively removed layer by layer

- Debris extraction and fume control, where vaporized material is filtered safely

- Post-clean inspection and verification, where surface quality and integrity are confirmed

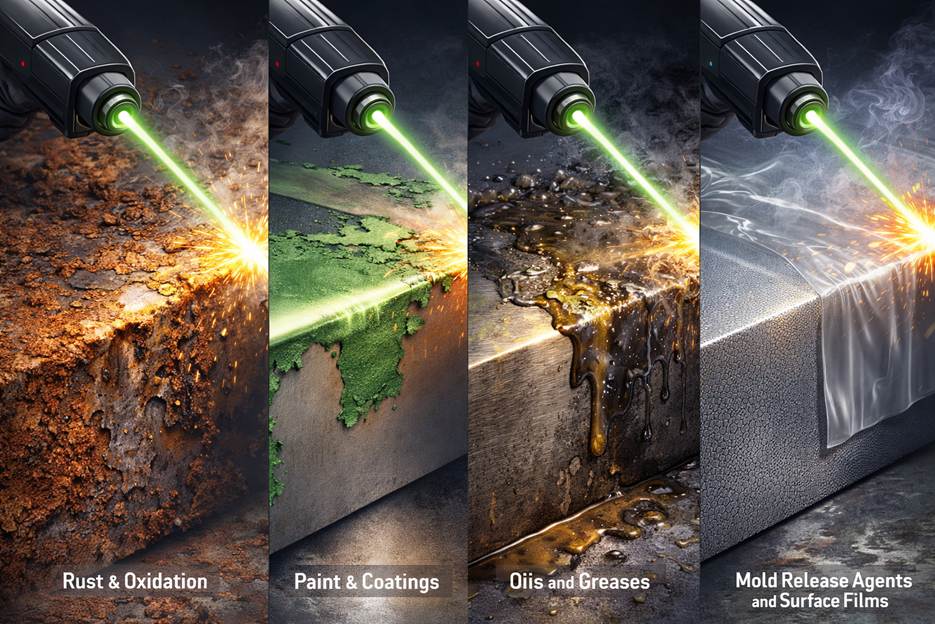

What Types of Contaminants Can Laser Cleaning Remove?

Laser cleaning removes a wide range of surface contaminants by targeting materials that absorb laser energy more readily than the base substrate. This capability allows a single system to handle multiple cleaning tasks across different industries. The most common removable contaminants include corrosion products, coatings, residues, and surface films. Each category responds differently to laser energy, which makes parameter control essential for safe and effective cleaning.

Rust and Oxidation

Rust and oxidation are corrosion products that form when metals react with oxygen and moisture. Laser cleaning removes rust by heating the oxide layer until it detaches, while leaving the underlying metal unaffected. This makes laser cleaning especially valuable for maintenance, restoration, and pre-weld preparation.

Paint and Coatings

Paint and coatings are protective or decorative layers applied to metal and composite surfaces. Laser cleaning selectively removes these layers, allowing precise stripping without roughening the substrate. This capability is widely used in aerospace refurbishment and automotive manufacturing.

Oils, Grease, and Industrial Residues

Oils and greases are organic contaminants that accumulate during machining and forming operations. Laser cleaning vaporizes these residues instantly, leaving a dry, residue-free surface ready for bonding or coating.

Mold Release Agents and Surface Films

Mold release agents and surface films are thin layers used in molding and casting processes. Laser cleaning removes these films without damaging molds, thereby extending tool life and improving part quality.

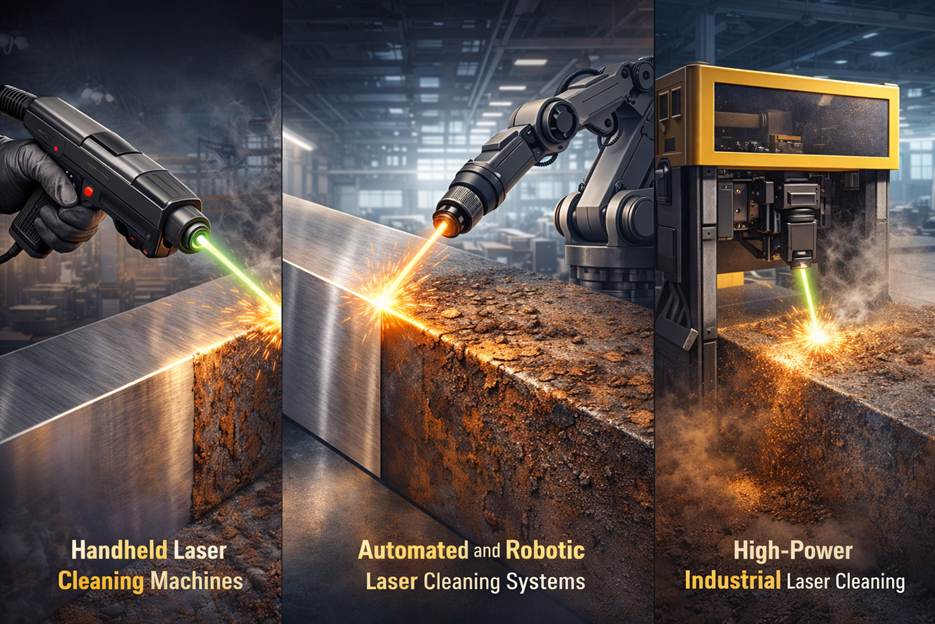

What Types of Industrial Laser Cleaning Machines Exist?

Industrial laser cleaning machines are categorized based on power level, mobility, and automation capability. Each category serves different operational needs while relying on the same core laser technology. Selecting the right machine depends on production volume, surface size, and integration requirements.

Handheld Laser Cleaning Machines

Handheld laser cleaning machines are portable systems designed for flexibility and on-site work. They are usable for maintenance, spot cleaning, and field repairs where mobility is essential. These machines typically use fiber laser technology and are common in shipyards, workshops, and restoration projects.

Automated and Robotic Laser Cleaning Systems

Automated and robotic laser cleaning systems integrate laser heads with CNC or robotic platforms. These machines are usable in high-volume manufacturing environments where repeatability is critical. They follow programmed paths and deliver consistent results across complex geometries.

High-Power Industrial Laser Cleaning Systems

High-power industrial laser cleaning systems deliver greater energy output for thick coatings and large surface areas. These machines are usable in heavy industry, steel processing, and infrastructure maintenance. Manufacturers increasingly rely onindustrial laser cleaning machinesto replace chemical baths and abrasive blasting with a digitally controlled, waste-free process.

What Are the Advantages of Industrial Laser Cleaning?

Industrial laser cleaning offers multiple advantages that directly address the limitations of traditional surface preparation methods. There are seven key advantages associated with laser cleaning technology.

- Reduce environmental impactby eliminating chemical waste and abrasive media

- Improve surface precisionby preserving geometry and tolerances

- Eliminate consumablesby operating without solvents or blasting grit

- Enhance process controlthrough adjustable and repeatable parameters

- Support automationby integrating with robotic and CNC systems

- Lower long-term operating costsby reducing waste handling and downtime

- Enable selective cleaningfor sensitive and high-value components

What Are the Limitations of Industrial Laser Cleaning?

Despite its advantages, industrial laser cleaning also presents limitations that must be considered. There are five main disadvantages associated with laser cleaning systems.

- Require higher upfront investmentcompared to basic abrasive equipment

- Limit effectivenesson extremely thick or multi-layer coatings

- Demand skilled operatorsfor correct parameter selection

- Require safety infrastructuresuch as enclosures and fume extraction

- Restrict productivityfor vast surface areas compared to blasting

Industrial Laser Cleaning vs Chemical Cleaning

Industrial laser cleaning offers a cleaner, more controllable alternative to chemical cleaning. Chemical cleaning relies on solvents and acids, while laser cleaning removes material through selective energy absorption. Laser cleaning produces minimal waste, reduces regulatory burden, and improves repeatability. Chemical processes introduce disposal costs, worker exposure risks, and inconsistent results. A comparison table here should evaluate environmental impact, safety, waste generation, operating costs, precision, and compliance.

Industrial Laser Cleaning vs Abrasive Blasting

Industrial laser cleaning offers higher precision and surface preservation than abrasive blasting. Abrasive blasting mechanically removes material, which can alter surface finish and tolerances. Laser cleaning removes only targeted contaminants and operates without consumables. Blasting systems require continuous media replacement and generate significant dust and waste. A comparison table here should summarize differences in surface finish, waste, safety, accuracy, and cost.

What Industries Use Industrial Laser Cleaning?

Industrial laser cleaning is used across industries where surface quality and cleanliness are essential. Eight primary industries rely on laser cleaning technology.

- Automotive manufacturing for weld preparation and paint removal

- Aerospace for oxide removal and sensitive component maintenance

- Shipbuilding for corrosion control

- Heavy equipment maintenance for rust and grease removal

- Electronics manufacturing for delicate surfaces

- Mold and toolmaking for mold maintenance

- Energy and power generation for turbine cleaning

- Heritage restoration for non-destructive surface treatment

How Safe Is Industrial Laser Cleaning?

Industrial laser cleaning is safe when proper controls and procedures are in place. Modern systems incorporate safety classifications, enclosures, and interlocks to minimize operator exposure. When used correctly, laser cleaning eliminates chemical handling risks and reduces airborne particulates.

What Safety Measures Are Required for Laser Cleaning?

Laser cleaning requires a structured set of safety measures. There aresix essential safety measuresinvolved.

- Laser-rated protective eyewear

- Controlled or enclosed work zones

- Fume extraction and filtration

- Safety interlocks and emergency stops

- Operator training

- Compliance with laser safety standards

How Much Does Industrial Laser Cleaning Cost?

Industrial laser cleaning systems typically range from $30,000 to over $300,000, depending on configuration. Operating costs are lower than those of chemical or abrasive systems because no consumables are required. Five main cost factors influence pricing.

- Laser power level

- Degree of automation

- Application type

- Duty cycle

- Maintenance requirements

How to Choose the Right Industrial Laser Cleaning System?

Choosing the right industrial laser cleaning system involves evaluating application requirements and operational constraints. There are five main steps involved in system selection.

- Assess material and contaminant type

- Define the required cleaning speed

- Evaluate automation needs

- Plan safety infrastructure

- Align system capabilities with the budget

What Are Common Mistakes When Implementing Laser Cleaning?

The most common mistakes include selecting underpowered systems, using incorrect parameters, neglecting operator training, and underestimating safety requirements. These issues are preventable through proper assessment and supplier consultation.

Is Industrial Laser Cleaning Worth It for Your Operation?

Industrial laser cleaning is worth it for operations that prioritize precision, sustainability, and long-term efficiency. While upfront costs may be higher, reduced waste, lower operating expenses, and improved surface quality often deliver strong returns.

Conclusion

Industrial laser cleaning represents a fundamental shift in how industries approach surface preparation. By replacing chemicals and abrasives with controlled laser energy, manufacturers achieve greater precision, enhanced safety, and compliance with environmental regulations. As sustainability and efficiency continue to shape industrial decision-making, laser cleaning stands out as a future-ready solution that delivers measurable value.