Industrial plastics in engineering.

Industrial Plastics Theory and Applications in Engineering PDF

By Mike Sondalini

Mike starts off by introducing Polyethylene's industrial plastics theory and applications, as it is the most commonly used plastic in engineering. Then the reader is ready to dive into the types of plastic welding. Also covered are gluing plastic pipes and fiberglass repair techniques. 8 pages.

Mike answers 'Why use plastics in engineering', and explains the two families of plastics. Then he goes into the heat types of plastic welding, as well as good plastic welding practices. In the gluing plastic pipes section, the reader learns pipe end preparation is everything. This PDF wraps up with one of the most common fiberglass repair techniques.

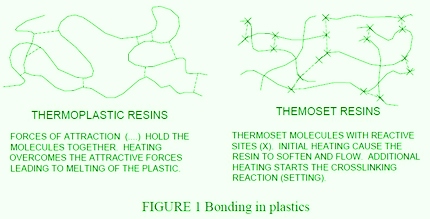

The difference between the two families of plastic results from how the macromolecules (See article 183 on Polyethylene) bond together at the atomic level. Thermoset molecules are triggered by heat to chemically react and weld together. Thermoplastic molecules are attracted to each other but do not chemically bond. Figure 1 shows the difference in the type and number of bonds between thermoset and thermoplastic materials.

Industrial plastics theory and applications PDF - Contents:

Poyethylene - its properties and uses.

Polyethylene is one of the most commonly used engineering plastics. Its chemical resistance properties and ease of fabrication make it popular in the chemical industries. Its molecular structure provides the key to its versatility.

Types of plastic welding.

Welding can join thermoplastic parts together. It can be by melting the surfaces and pressing them together or by extrusion welding with a filler rod. Several methods of welding are available. Proper manual techniques are critical to success as is the pressure testing of pressure parts.

Gluing plastic pipes so you can trust them.

Adhesive joined plastic pipes have been known to separate at the glued joint. The joining of plastics using glue requires the glue to 'hook' into a clean, rough surface. The section explains the preparation procedure to use and the reasons behind its use.

Fiberglass repairs techniques.

Fiberglass is a glass fiber-reinforced plastic composite with excellent chemical resistance properties. Its physical properties, selection of resins and glass, method of construction and fabrication, and peculiar repair requirements must be appreciated when using this material.

Gain valuable insight and understanding; get your copy of Industrial plastics theory and applications PDF today!

![]() Download right away in a printable PDF format!

Download right away in a printable PDF format!

$12.50

An Excerpt From Industrial plastics theory and applications PDF

"Types of Plastic Welding"

Plastic Socket welding is done by using heated tools to melt the outside of the first few centimeters of a pipe end and the first few

centimeters on the inside of the socket fitting. The pipe is pushed inside the socket and held in place till it cools. ...

Plastic Electro-socket welding is the same as socket welding except an electrical wire is installed in the fitting when it is made. The pipe

is pushed into the socket and the wire is connected to a power source. The wire heats up and melts the plastic surfaces. When the

power is removed the plastic cools down. ...

Plastic Extrusion welding is used to weld plastic sheets together. A plastic wire from 2mm to 6mm in diameter, depending on the size of

the extruder, is fed through a heated barrel where it melts. The tip of the extruder heats the plastic sheet and melts the surface. ...

Plastic Hot air gun welding is used for light-duty fabrication and tacking large fabricated items together before finally extrusion welding

them. With this method, a hand-held plastic wire is pushed into the joint made by the corner edges of the two parts. ...

Please contact us with any questions.