Palletizing Systems for the Food and Beverage Industry

- Home >

- articles >

- electrical >

- engineering >

- palletizing systems for food industry

Palletizing Systems for the Food and Beverage Manufacturing Industry

Let's explore palletizing systems for the food and beverage manufacturing industry.

SECTIONS

Palletizing systems manage products with ease, simplifying manufacturing and distribution procedures. A palletizing system consists of a palletizer machine and supporting conveyor systems moving products in and out of the palletizer. In the food and beverage industry, palletizing systems need special features. They differ from those used in other manufacturing sectors.

A key difference in palletizing systems in the food and beverage industry is their need to handle specialized materials.

Modular Palletizing Systems

Food and beverage products come in many shapes and sizes. Their packaging includes bottles, jars, boxes, and pouches. So, palletizing systems for this industry must be versatile. They categorize and manage diverse products with precision. This requirement makes modular palletizing systems popular; they can quickly adapt to the ever-changing product production.

What are modular palletizing systems?

Modular palletizing systems are a type of palletizer. They have various modules that work together. This design gives them versatility in handling different products. Modular palletizing systems have three main types: conventional, robotic, and hybrid.

The Three Modular Palletizing Types

CONVENTIONAL

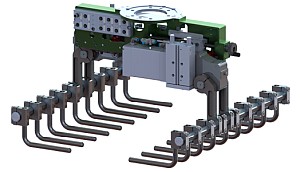

A conventional system consists of a palletizer and conveyor modules. An example would be the layer palletizer/low-level palletizer with the sliding plate. Another example, shown above, is a pusher. Together, they form a conventional palletizer.

ROBOTIC

The second, more modern type is the robotic module. The robot is in a cage [cell]. The robot contributes to precise and efficient handling of a wide range of packaging formats using various End-of-Arm grippers.

HYBRID

The third type is a hybrid of the other two modular palletizing systems. Examples would be conventional layer palletizing and robot-using layers to build a complete pilot of products on a turntable.

Robotic Palletizer end-of-arm tools (EOAT)

You can use this versatility with various end-of-arm tools (EOAT) and grippers. They must handle many packaging formats. They must also ensure gentle, precise handling to maintain product integrity.

VACUUM GRIPPER

A vacuum gripper is a tool used in food and beverage manufacturing. It uses vacuum pressure to create a secure grip on products. This gripper is for items with smooth, flat surfaces, like bottles, boxes, and pouches. It provides gentle, reliable handling. The vacuum is an open-air system unsuitable for direct food contact. This equipment facilitates package relocation and stacking onto pallets.

RIGID GRIPPER

A rigid gripper is a tool used in food and beverage manufacturing. It has a firm, inflexible design. It grasps tightly, moving objects with precision. Rigid grippers often handle heavier, robust items like packaged goods. They ensure a secure grip and control during palletization.

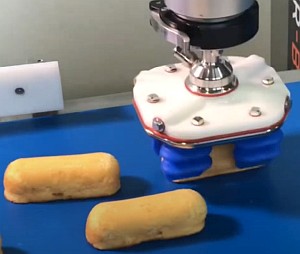

SOFT GRIPPER

A soft gripper is a tool for gripping delicate, lightweight foods and drinks. This gripper uses soft, flexible materials to handle food packaging. It allows for careful, non-damaging product manipulation during palletizing.

Food and beverage industry hygiene

Another critical factor in palletizing systems for the food and beverage industry is hygiene. Food and beverage manufacturing must meet strict hygiene standards. The standards are to ensure product safety and quality. Other manufacturing industries do not have such strict requirements. Palletizing systems for this industry use food-grade, easy-to-clean materials and finishes.

Food-Grade Palletizing System Requirements:

✓ Non-toxic

✓ Non-absorbent

✓ Resistant to corrosion

✓ Resist staining

✓ Compatible with various cleaning agents

Also, these systems often have wash-down features and a sanitary design to minimize contamination risk.

Food & Beverage Operating Environment

The operating environment has a profound impact on palletizing systems. The food and beverage environment has requirements, unlike other manufacturing sectors. So, it adds to the specific material handling and hygiene concerns. Food and beverage factories often need more floor space. They may also need the palletizing system to fit into an existing production line. Systems must integrate seamlessly with adjacent machines. Also, food and beverage production may involve temperature-sensitive products. So, palletizing systems for this industry must work in temperature-controlled environments. They must also ensure that they maintain the integrity of the products they are handling.

Cooler or freezer-rated palletizer:

- Operates in -40deg temperature (-20deg preferred)

- Low-temperature lubricants

- Plastic parts rated for cold-storage rooms

- Small footprint

- Palletizing robots may need a thermal cover

- Maybe heating system

- Use electrical actuators, not air-controlled

Food and Beverage Regulations

Food and beverage sector regulations influence palletizing systems' configuration and operation. These systems must meet food safety, labeling, and traceability regulations. They are industry-specific. Designers and food manufacturers must know the FDA and FSIS rules for palletizing systems. Also, the manufacturers must understand the relevant CDC, EPA, APHIS, OSHA, and ISO standards.

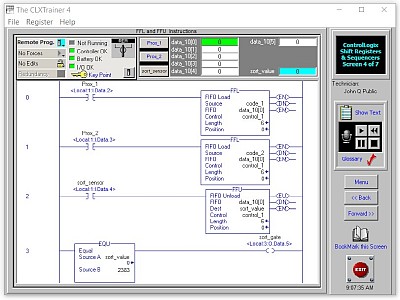

Palletizing systems for the food and beverage industry often use advanced technology. The technology includes vision systems for quality inspection, bar-coding, and labeling. They also have software for tracking products throughout the palletizing process.

Pallet Tracking:

- Barcode labels

- RFID tags

- GPS

- IIoT

- PLC

Tracking can even be accomplished in gravity palletizing systems. An entry/exit sensor is in place at the gravity palletizer. Then, a first-in and first-out (FIFO) programming methodology tracks the product in a gravity palletizing system.

In conclusion, palletizing systems for food and beverage manufacturing are unique. They must meet high standards for versatility, hygiene, and sanitation. They also must follow industry regulations and suit the operational environment. Palletizing system designers and users must consider these factors. This article is excellent background knowledge for those asking how to choose a palletizing system.

Related Courses:

OSHA Forklift Certification Training Course

Automation Technician Training Bundle

Modernization of Industrial Machines eBook

Related Article:

Maintenance Safety Training Programs Cal-OSHA Example

Reducing Costs With Packaging Automation