Heat Exchangers Types, Theory and Basics Course

- Home >

- vocational-training >

- mechanical >

- heat exchangers cbt

a great animated study guide for related heat exchanger types.

This course covers most exchanger types and related information in the industry.

Tap the above picture to see heat exchangers course demo.

Full Heat Exchanger Basics Demo - Content

heat exchanger training program

ESBN: II1-6798-6040-KM70

Description: (40 hrs)

This training course on heat exchangers covers many types. They include:

- Shell & Tube Exchangers (TEMA type)

- Air-Cooled Exchangers

- Plate and Frame Exchangers

- Spiral Exchangers

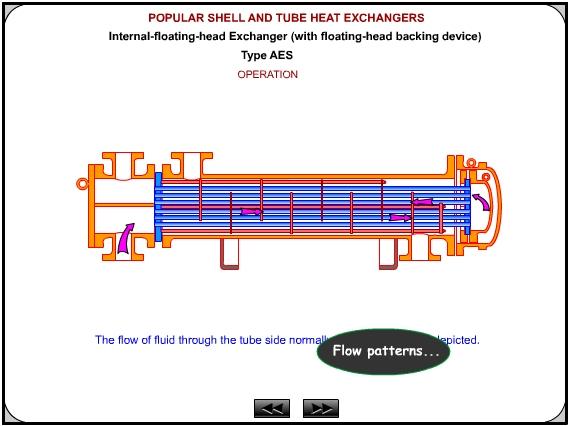

It details the operation and maintenance of popular TEMA types: AES, BEM, AEP, CFU, AKT, and AJW.

Using Heat Exchanger graphics and animations in the course helps. It makes the operating principle and maintenance procedures very clear. These include testing and repairing the Heat Exchanger. The Heat Exchanger training program explains how to assemble and dismantle Heat Exchangers. Animated scenes show how Heat Exchangers work. We include a glossary, skills tests, and certificate printouts.

- The course covers an extensive range of heat exchangers.

- Experts cover popular exchangers like "Shell and Tube" in great detail.

- Extensive 2D/3D graphics, models, and animations.

- You can assemble over 250 exchangers with games in the TEMA selection!

- Glossary, skills tests, and certificate printouts.

Who Can Benefit:

Untrained students and maintenance staff will find this training on heat exchangers helpful. It will boost their knowledge and confidence in maintenance work. Those with prior training may find this program a good refresher. They may also learn important information outside of their original training.

Hardware Lock:

This course is also available using a "Hardware Lock" licensing method. Many users want to use the software on multiple computers. For example, they want to work with it on both their office and home computers. This Hardware Lock method allows users to install the software on as many computers as they like. They only need to enter the key on whichever computer they want to use the software. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:

You can also ask us to embed your company logo in the training software for the hardware lock option.(Please note the URL of your company logo in the comments when ordering, or email your logo to us to use this feature.)

We will send an email confirming the order within 24 hours after purchase. If you ordered a downloadable version, check your email. It has the download link and activation code. We send a second email with tracking info if you ordered one of the shippable versions.

Download (1 Installation on 1 PC, Unlimited users, 1 User at a time.) $149

1 Hardware Lock (Unlimited Installations, Unlimited number of PCs, 1 User at a time.) $349

1 Network Hardware Lock (Network Installation, Unlimited number of PCs, 10 Users at a time.) $1049

1 Network Site License (Network Installation, Unlimited Simultaneous PCs and Users) $2100

Course Table of Contents

1. Different Types of Heat Exchangers

- 1.1. Introduction

- 1.2. Shell and Tube Heat Exchanger

- 1.3. Air Cooled Heat Exchanger

- 1.4. Spiral Plate Heat Exchanger

- 1.5. Plate and Frame Heat Exchanger

- 1.6. Plate and Fin Heat Exchanger

- 1.7. Evaporative Cooled Heat Exchanger

- 1.8. Spiral Tube Heat Exchanger

- 1.9. Double Pipe Heat Exchanger

- 1.10. Bayonet Heat Exchanger

- 1.11. Patterned Plate Heat Exchanger

- 1.12. Mechanically Aided (Scraped Surface & Thin Film Exchanger)

- 1.13. Jacketed Vessels

- 1.14. Fired Heaters

- 1.15. Regenerative Heat Exchanger

2. Detailed Description of Popular Shell and Tube Exchangers

- 2.1. Principle of Operation

- 2.1.1. Fixed-Tube-Sheet Heat Exchanger (BEM)

- 2.1.2. U-Tube Heat Exchanger (CFU)

- 2.1.3. Packed-Lantern-Ring Heat Exchanger (AJW)

- 2.1.4. Outside Packed Floating Head Exchanger (AEP)

- 2.1.5. Internal Floating Head Exchanger (AES)

- 2.1.6. Kettle Type – Pull-Through Floating Head Exchanger (Reboiler / AKT)

- 2.2. Construction

- 2.2.1. Exploded Views of Fixed-Tube-Sheet Heat Exchanger

- 2.2.2. Exploded Views of U-Tube Heat Exchanger

- 2.2.3. Exploded Views of Packed-Lantern-Ring Heat Exchanger

- 2.2.4. Exploded Views of Outside Packed Floating Head Exchanger

- 2.2.5. Exploded Views of Internal Floating Head Exchanger

- 2.2.6. Exploded Views of Pull-Through Floating Head Exchanger

- 2.3. Hydraulic Pressure Testing and Maintenance

- 2.3.1. Fixed-Tube-Sheet Heat Exchanger

- 2.3.2. U-Tube Heat Exchanger

- 2.3.3. Packed-Lantern-Ring Heat Exchanger

- 2.3.4. Outside Packed Floating Head Exchanger

- 2.3.5. Internal Floating Head Exchanger

- 2.3.6. Pull-Through Floating Head

- 2.4. Tube-Side Construction

- 2.4.1. Tube-Side Header

- 2.4.2. Bonnet

- 2.4.3. Channel

- 2.4.4. High Pressure Closures

- 2.4.5. Tube-Side Passes

- 2.4.6. Integrally Finned Tubes

- 2.4.7. Tube Layout

- 2.4.8. Tube Sheet

- 2.4.9. Rolled Tube Joints

- 2.4.10. Welded Tube Joints

- 2.4.11. Tubes and Tolerances

- 2.5. Shell-Side Construction

- 2.5.1. Shell Sizes

- 2.5.2. Shell Side Arrangements

- 2.6. Baffles and Tube Bundles

- 2.6.1. Segmental Baffles

- 2.6.2. Tie Rods and Spacers

- 2.6.3. Impingement Baffles

- 2.6.4. Vapor Distribution

- 2.6.5. Tube-Bundle Bypassing

- 2.6.6. Longitudinal Baffles

3. Air Cooled Exchangers

- 3.1. Operation & Flow Path Across the Exchanger

- 3.2. Exploded Views

- 3.3. Maintenance Details

4. Plate and Frame Exchangers

- 4.1. Operation & Flow Path Across the Exchanger

- 4.2. Exploded Views

5. TEMA Understanding

- 5.1. Selection and Game on TEMA Types

- 5.1.1. Front End Stationary Head Type

- 5.1.1.1. Channel and Removable Cover

- 5.1.1.2. Bonnet (Integral Cover)

- 5.1.1.3. Channel Integral with Tube-Sheet and Removable Cover

- 5.1.1.4. Channel Integral with Shell and Removable Cover

- 5.1.1.5. Special High Pressure Closure

- 5.1.2. Shell Types

- 5.1.2.1. One Pass Shell

- 5.1.2.2. Two Pass Shell with Longitudinal Baffle

- 5.1.2.3. Split Flow

- 5.1.2.4. Double Split Flow

- 5.1.2.5. Divided Flow

- 5.1.2.6. Kettle Type Re-boiler

- 5.1.2.7. Cross Flow

- 5.1.3. Rear End Head Type

- 5.1.3.1. Fixed Tube Type – 'A' Stationary Head

- 5.1.3.2. Fixed Tube Type – 'B' Stationary Head

- 5.1.3.3. Fixed Tube Type – 'N' Stationary Head

- 5.1.3.4. Guided Packed Floating Head

- 5.1.3.5. Outside Packed Floating Head

- 5.1.3.6. Floating Head with Backing Device

- 5.1.3.7. Pull-Through Floating Head

- 5.1.3.8. U-Tube Bundle

- 5.1.3.9. Externally Sealed Floating Head

- 5.1.1. Front End Stationary Head Type

- 5.2. Skills Test

6. Glossary of Technical Terms

7. Conventional and Interactive Skill Tests with Evaluation

Related Products:

Infrared Inspections for Petrochemical Companies

Gas and Air Compressor Training

Centrifugal Pumps and Troubleshooting Guide

Hydraulics Training Certificate Course

Industrial Hydraulic systems and Circuits

Hazardous Area Instrumentation Training

Handbook for Machining Equipment Maintenance

Please contact BIN95 with your questions and comments.