ControlLogix - RSLogix 5000 Training

- Home >

- vocational-training >

- plc-training >

- allen-bradley >

- controllogix rslogix 5000

CLXTrainer training course software for ControlLogix & RSLogix 5000

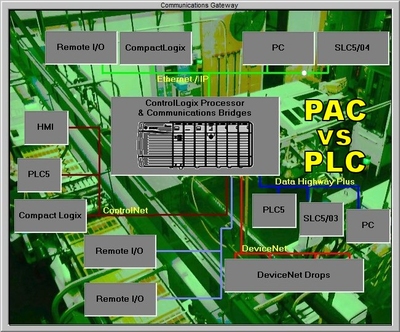

The CLXTrainer ControlLogix Training Software includes an introduction to ControlLogix with an overview of RSLogix 5000. This courseware has a final exam, laboratory manual, and the ability to print a Certificate of Completion all built into it. No additional software is needed to complete this course. This computer-based training software is ideal for learning the fundamentals of RSLogix 5000 programming software and the Allen Bradley Programmable Automation Controller (PAC). RSLogix 5000 is the programming software for ladder logic, structured text, function block, drive, and motion control programming of the AB Logix hardware platform.

The CLXTrainer certificate course software download never expires. With 63 built-in simulations, it also provides an excellent refresher for those not using RSLogix 5000 software frequently. This Programmable Automation Controller course software includes a 71-page PAC Laboratory Manual built into it, with questions and exercises for each of the 15 sections. The screens demonstrating the programming instructions have the look and feel of RSLogix 5000 (Allen Bradley's PAC programming software).

Controllogix and RSLogix 5000 are PAC (Programmable Automation Controller, IE: Industrial Computer). Before taking the PAC course on this page, you should take our PLC Programming Basics course.

RSLogix 5000 Training- The CLXTrainer (30hours)

Prod #: CLX5000-BIN

ControlLogix-RSLogix 5000 Training Content:

- Introduction to ControlLogix

- Overview of RSLogix5000

- ControlLogix architecture

- ControLogix memory

- Project organization

- Data file types

- ControlLogix bit instructions

- Timer instructions

- Counter instructions

- Data collecting

- File/data manipulation

- Shift registers/sequencers

- Program control instructions

- Documenting programs

- Communications

_____________________

--> 63 RSLogix 5000 simulations.

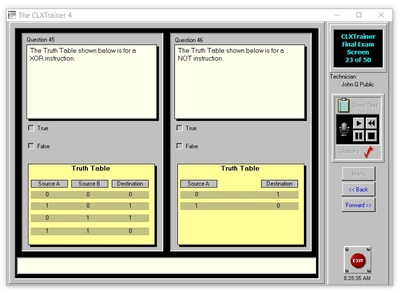

--> Final exam.

--> 71-page laboratory manual.

--> Password-protected student log file.

--> Ability to print a certificate of completion.

--> Ability to print test responses.

This ControlLogix Training Software runs on all Windows operating systems. Suppose your equipment has any of the following Allen-Bradley Logix platforms: ControlLogix, FlexLogix, CompactLogix, and SoftLogix5800, as well as PowerFlex 700S with DriveLogix. In that case, you can benefit from this training. (All series 1756)

PLC Training Course Outline:

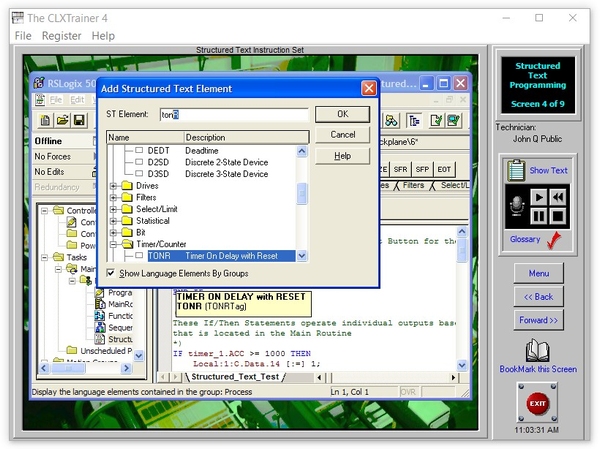

1 of 63 RSLogix 5000 Simulations

Most of this course is RSLogix 5000 Simulators.

By the course mainly using interactive simulations and some animations, the learner understands better and remembers content longer. This hands-on training approach makes this course more interactive and fun than the typical PowerPoint-style or online video courses. The ControlLogix hardware section also uses simulations. The RSLogix 5000 I/O module configuration simulator and the networking driver setup simulations are two examples.

More screenshots and simulation recordings are below...

Within 24 hours of placing the order, you will receive an email with a download link, activation information, or tracking information if the order is shipped.

Order a Single Student License above or unlimited students/installs per physical site with the Site License.

For unlimited physical site licenses (locations), please Request a Quote for the Enterprise License.

After explaining the difference between a PLC and a PAC, the video below introduces the ControlLogix - RSLogix 5000 course described on this page. We often create extra supplementary free learning material for our courses and place them on this site and our YouTube channel so that the learner can learn even more.

ControlLogix & RSLogix 5000 Course Simulation Examples:

Below are screen recordings of a student interacting with 6 of the 60 simulations built into this course. There are two categories of simulations: ControlLogix (hardware) setup and RSLogix 5000 simulations (automation control programming software).

With the PLC, adding an I/O module was practically plug-and-play. But with a PAC, they must be configured. There could be firmware compatibility issues, etc. So, the course has a ControlLogix simulation to walk the learner through the process. Above is a screen recording of students using the simulator to learn and practice.

The above screen recording is the RSLogix 5000 programming simulator. It is used extensively throughout the course. These simulators use pre-written programs only, each covering the topic discussed. For example, every programming instruction covered has a practical, real-world application of the instruction written in the simulator to interact with.

Some simulators are custom just for the topic, like the above screen recording of the MCR instruction simulator. There is another for the JMP instruction, JSR instruction, etc. An audio and text narration walks the user through the simulation. The user can experiment with operating the simulated program until they feel comfortable with how it's applied in automation control.

Although Ladder Logic is the most common programming language used in programmable automation controllers (PAC), Structured Text is the second most popular language. The above simulation is one of the Structured Text sims.

The above screen recording is of the function block programming interactive simulation. The simulator serves as an introduction to the other less-used programming languages. However, the course primarily focuses on Ladder Logic.

The above recording is of the MVM instruction simulator being used. 26 of the most used PLC instructions are taught in this RSLogix 5000 course. For this course, about 30% of it is interactive simulations.

ControlLogix RSLogix 5000 Course - Features:

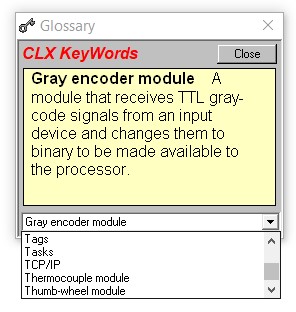

The CLXTrainer also includes an extensive programmable automation control glossary of terms standard to PAC technology.

Every screen has audio narration, text transcript, and the ability to bookmark pages. There is also a built-in glossary. The CLXTrainer comes with an interactive, self-scoring final exam! Along with the interactive "self-scoring" final exam, the student can print an RSLogix 5000 training certificate of completion upon scoring 85% or better.

School and Company Multiple User Licenses:

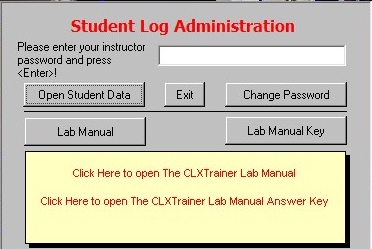

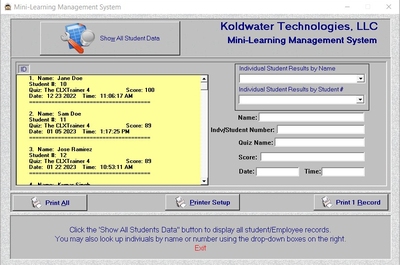

Built into the Site and Enterprise-licensed versions of this course software is a mini-LMS.

With the site licenses, students can print a certificate of completion, saving the student's score to a "student log file" accessible by Site and Enterprise license holders. That feature and others make the site license purchasing option perfect for Technical Schools, Community Colleges, Universities, Apprenticeship Programs, and company training departments.

A ControlLogix/RSLogix 5000 PDF Laboratory Manual is included with the course. It consists of optional questions and one or more exercises for each of the 15 sections. Some exercises in the lab manual require the instructor to make Rockwell's RSLogix 5000 software available to students/employees. This lab manual's primary purpose is to serve as an additional tool for the instructor to help students understand more and support the instructor in evaluating the student's understanding better. The individual purchasing this course can also benefit by studying the lab manual independently.

Because this AB/Rockwell RSLogix 5000 course starts from a beginner level and uses interactive simulations to make learning easier, this course will also work for capable students without previous PLC experience. Individuals taking this course should follow the recommended learning path at the bottom of this page and take our Motor Controls and PLC Basics course first.

The 71-page Lab Manual PDF is an excellent instructor aid.

Within 24 hours of placing the order, you will receive an email with a download link, activation information, or tracking information if the order is shipped.

Order a Single Student License above or unlimited students/installs per physical site with the Site License.

For unlimited physical site licenses (locations), please Request a Quote for the Enterprise License.

Learning Path:

We recommend:

1st Electrical Motor and Controls Course

2nd PLC Basics

3rd Electrical and PLC Troubleshooting

4th HMI Basics

5th PAC - ControlLogix and RSLogix 5000 (the page you are on now)

6th Online PLC Structured Text Programming Basics Course

7th SCADA Basics

Related Titles:

Automation Technician's bundle (Save 32%)

Advanced PLC Programming Structured Text (ST) Examples

PLC Object-Oriented Programming Language Examples

PID Tuning Blueprint, Calculator, and Simulator Download

Before seeking PAC training (RSLogix 5000), we recommend you review the article PLC vs PAC Difference and take the PLC Programming Basics course.

All trademarks and trade names are the property of their respective owners. We are an independent training provider and not affiliated with Allen Bradley.