Industrial Troubleshooting - Electrical

- Home >

- articles >

- electrical >

- electrical industrial troubleshooting

Industrial Electrical Troubleshooting Advice

By Larry Bush

Troubleshooting In The Field - Motor Testing - Motor Controller - Programmable Logic Controllers (PLC)

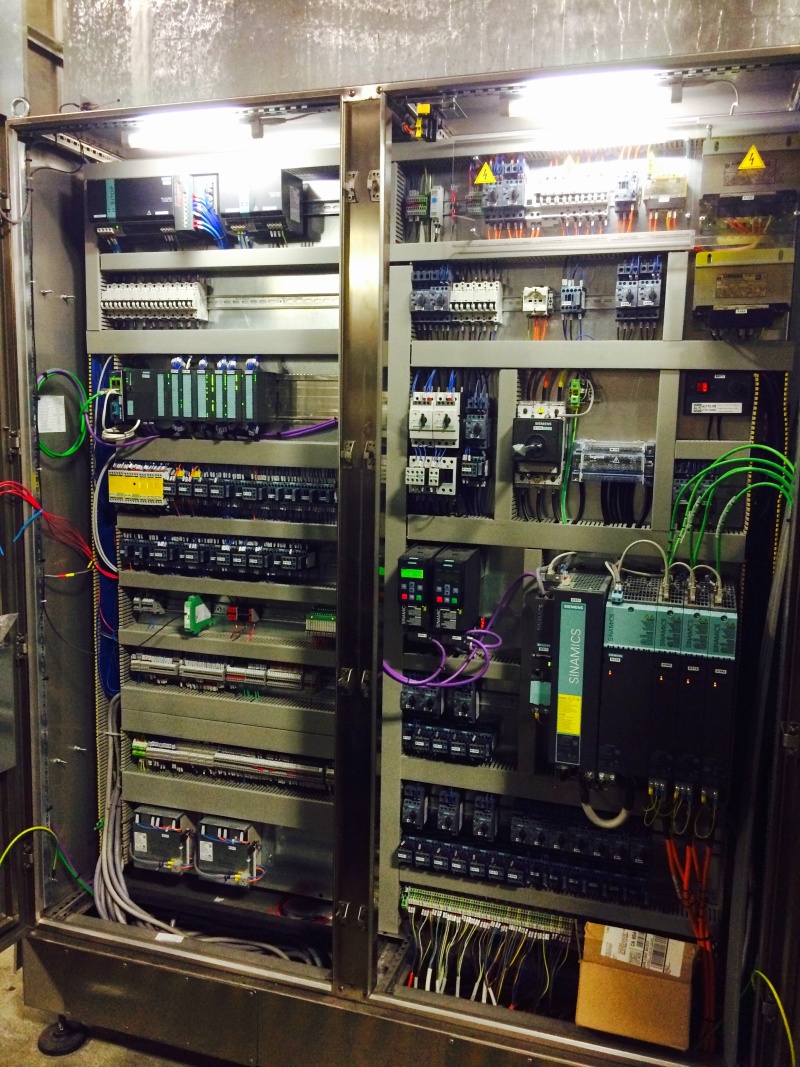

Industrial troubleshooting and electrical troubleshooting also require excellent computer skills. A laptop computer with PLC programming, communication, and operating programs is necessary for today's modern plant. Engineers, production supervisors, maintenance supervisors, maintenance technicians, electricians, instrument technicians, and maintenance mechanics must have PLC and computer knowledge, training, and troubleshooting skills. More about PLCs towards the end of this article.

Basic troubleshooting techniques apply to every situation and occupation. Identifying the problem(s) is essential to solving the issues. The inexperienced troubleshooter often mistakes one or more of the symptoms for the problems. Solving the symptom(s) will typically postpone the problems to a later date. By this time, the issues may have grown to mountainous proportions.

An example is when a person experiences a headache and takes a mild pain reliever, such as aspirin. The problem might be any number of things: eyes need to be checked, medication or lack of medication, muscle strain, stress, tumor, blood vessel blockage, or old war injury. The same thing occurs in the industry; a fuse in a circuit blows, and the maintenance person gets the replacement fuse and inserts it into the fuse holder. Depending on the complexity of the circuit, many things could have caused the fuse to blow.

The excess current caused the fuse to open (blow). The excess current could have been caused by overload on the load, short circuit between the wires, grounded wires, short circuit in the load, ground in the load, voltage spike, voltage droop, etc. If the maintenance person does not troubleshoot the circuit before replacing the fuse and restoring power, negative consequences could arise.

It is not uncommon for a process to develop several small problems and continue to function at a degraded level of operational capability. Then, one more small problem occurs, and the whole process breaks down. Finding and correcting the last problem will not necessarily restore the operational capability of the process. The process continued operations with minor issues, but the small problems may not allow the process to restart from a dead stop. All the other minor issues must be identified and corrected before the process is restored to full operational capability.

This situation arises in the industry as well as a person. The person can continue to function with several minor problems, such as fatigue, blood pressure problems, hardening of the arteries, and artery blockage. Still, one more small blood clot in the wrong place could easily cause the death of the person. Clearing the blood clot does no good to the person. They will not be restored to full operational capability.

Field Electrical Troubleshooting:

Unless prior experience dictates otherwise, always begin at the beginning.

Ask questions of the Operator of the faulty equipment:

- Was equipment running when the problem occurred?

- Does the Operator know what caused the problem, and if so, what, in their opinion, caused the problem?

- Is the equipment out of sequence?

- Check to ensure there is power.

- Turn on the circuit breaker, ensure the motor disconnect switch is on, and operate the start button/switch.

- Use a voltmeter to check the following at the incoming and load side of circuit breaker(s) and/or fuses, ensure that voltages are normal on all legs, and read voltage to ground from each leg.

- Main power, usually 460 VAC between phases and 272 to ground.

- Control & power, 208/240 between phases and 120 to the ground and 120 VAC to neutral on a grounded system.

- Low voltage control power, usually 24 to 30 VAC and/or VDC between phases and possibly to ground, is typically negative and connected to ground.

TIP: Add this Electrical Motor Troubleshooting chart link to your favorites so you can call upon your smartphone to guide you during electrical motor troubleshooting.

Check controlling sensors in the problem area, then make a complete check of all sensors, limit switches, and other switches to ensure they are in the correct position, have power, are programmed, set, and are functioning correctly.

If and when a problem is found, whether electrical or mechanical, the situation should be corrected, and the fault-finding began anew; a seemingly unrelated fault or defect could cause the problem.

When there is more than one fault, the troubleshooting is exponentially more difficult. Refrain from assuming all problems are solved after completing one; always test the circuit and operation before returning the equipment to service.

If available, check wiring diagrams and PLC programs to isolate problems.

Variable Frequency Drive (VFD) can be reset by turning the power off, waiting until the screen is blank, and restoring power; on some VFDs, press Stop/Reset, then Start.

Check that the wiring is complete and that wires and connections are tight, with no copper strands crossing from one terminal to another or the ground.

Ensure the neutral reading is good and the neutral is complete and not open.

Electric Motor Testing In Shop:

Before connecting a motor:

- Move motor to electric shop motor test and repair station.

- Connect motor leads for 460-volt operation and wrap connections with black electrical tape.

- Check motor windings with an ohmmeter; each reading between phases should be within one or two ohms of each other: A to B, B to C, and A to C.

- Use a megohmmeter to check insulation resistance to the ground of motor windings on the 500-volt scale; the minimum reading is 1000 ohms of resistance per volt of incoming power to which the motor will be connected.

- Connect the motor to power test leads and safety ground after checking that test lead power is shut off; secure the motor to the table to prevent the motor from jumping when started; turn disconnect on; press the start button; check "T" leads for motor amperage; check for abnormal sounds and heat in bearings or windings; clean the motor shaft; shut down and disconnect.

Electric Motor Testing In Field:

When a motor overload or circuit breaker trips and/or blows fuses, certain procedures and tests should be carried out:

- Lockout and tagout main circuit breaker;

- Test insulation resistance of motor wires and windings by using megohmmeter between T1, T2, & T3 leads and ground.

- Test "T" leads to motor with ohmmeter for continuity and ohmage of windings between A to B, B to C, A to C; each resistance should be within 1 or 2 ohms of each other; if the ohms readings are significantly different, or, if there is no continuity; go to the motor disconnect box, turn it off, perform the continuity and resistance test on the "T" leads, again; if the readings are good, the problem is in the wires from the motor controller to the disconnect switch;

- Check the three wires by disconnecting all three wires from the switch and twisting them together; go to the controller and check for continuity between A to C, B to C, and A to C; one or more wires will be open or grounded;

- The correct solution is to pull all new wires in from the controller to the motor disconnect switch. Whatever caused the problem may have damaged the other wires. Also, replace all wires.

- If the problem is on the motor side of the disconnect switch, open the motor connection box and disconnect the motor;

- Check the motor for resistance to the ground with a megohmmeter. If the reading is below 500,000 ohms, the motor is grounded and must be replaced;

- Test motor windings for ohms between phases with ohmmeter A to B, B to C, and A to C; readings should be within 1 or 2 ohms of each other; if readings indicate open or a significant ohmage difference, replace motor;

- If motor test readings are good, test the motor leads between the disconnect switch and the motor connection box for continuity and ground resistance. If readings are not good, replace wires;

- If all readings are OK, reconnect the motor, remove the lockout, and restore it to service; the problem could have been mechanical: an overload on the motor caused by the chain or belt, bad bearings, faulty gearbox, or power glitch.

Motor Controller:

- Check the motor Full Load Amps (FLA) at the motor and check the setting on the controller overload (OL) device; most newer OL devices are adjustable between specific ranges, and some older OL devices use heaters for a given amperage.

- If circuit disconnecting means in the controller is a circuit breaker, it should be sized correctly.

- If the disconnecting means is a Motor Circuit Protector (MCP), the MCP must be correctly sized for the motor it is protecting, and the MCP has a trip setting unit, which has to be correctly set based on the Full Load Amperage of the motor. Using a small screwdriver, push in on the screw head of the device and move to a multiple of thirteen of the FLA. For example, a motor FLA of 10 amps would require the MCP trip device to be set to an instantaneous trip point of 130 amps.

- Fuses protecting the motor should be the dual element or current limiting type based on the motor FLA.

PC PLC Training:

On-the-job training on PLCs is usually only effective once the person being trained has reached a certain level of expertise in several areas. Knowledge and skills in electricity, troubleshooting, and computer operation are necessary prerequisites to assimilate basic PLC training effectively. The author found that long-term retention of material studied was higher from a vocational course at a local junior college than from a fast-paced, cram course through a manufacturer.

The manufacturer's course covered essentially the same material as a course at the junior college (JC). The significant differences were the amount of study time and shop time. The JC course was four hours of class time per week for 15 weeks. There were three hours of shop time doing hands-on work on the problems and material covered in the first hour. Additional time was spent at home studying the manual and writing programs. Also, the JC was open at night for extra shop time on the PLCs and computers.

In contrast, the manufacturer's course was five, eight-hour days. Class work was extremely fast and condensed to cover the amount of material involved. The instructor was very knowledgeable and covered the course material as we tried to input the programs into desktop training equipment to see how they worked. By the end of each day, our minds were jammed with information. By the end of the week, we all passed the course, but I had difficulty remembering what we had studied on the first day.

Programmable Logic Controllers (PLC):

- Check to ensure the main power is on (120 VAC).

- Check 24V power available.

- Identify problem areas.

- Check sensor operation in the problem area.

- Check sensor Inputs to PLC.

- Check on PLC that a change in sensor state causes the corresponding Input LED on the PLC to go on or off.

- Identify Output controlled by Input on the PLC ladder diagram.

- Ensure that the Output LED is cycling on/off with the Input.

- Check that the Output voltage is correct and cycling on/off with the Input.

- Locate the Output device and ensure that voltage reaches the device and cycles with the Input.

- Ensure that the Output device works correctly (solenoid, relay, contactor, etc.).

- An Input or Output module can be defective in one area or circuit and work correctly in all other circuits.

- If each field circuit is not fuse-protected, the modular internal circuit becomes a fuse and can be destroyed by a field short circuit or any other over-current condition.

- Check the modular circuit; if it is bad, the module must be replaced after correcting the field fault.

- Shut down PLC before changing any module -main and 24V power.

- Locate fault in field circuit by disconnecting wires at module and field device. Check between wires for short circuits and to ground for short circuits; replace wire if a short circuit is found.

- Check the device for ground, short circuits, and mechanical and electrical operation. Always check the device for other faults, even when a problem is found in the wires. Problems in wires can cause a problem in the device or vice versa. If the device is defective, replace it and check the total circuit before placing it in operation. After restoring the circuit, check again to ensure the circuit and module are operating correctly.

- Check the power supply module; if there is no output, shut down the power and replace the supply module.

- The backplane can go bad. Some modules have power, and others have no, so replace the backplane.

- Sometimes, the PLC can be reset using the Reset key switch. Ensure that turning the PLC off won't interrupt other running sub-set programs. Turn the keys switch to the far right; after 15 seconds, turn to the far left, wait, and then return to the middle position. This operation should reset the program and enable a restart.

- The PLC program can have a latch relay without a reset under certain conditions. The key-switch reset may not affect the latch. Try turning the power to the PLC off and back on. This operation may reset the latch and allow the program to be restarted.

- The PLC is usually part of a control circuit supplied with 120VAC through a 460V/120V transformer as part of a system with motors, controllers, safety circuits, and other controls. Occasionally, cycling the main 480V power off/on will be necessary to reset all the safety and control circuits.

- Possession and use of an up-to-date ladder diagram, elementary wiring diagram, manufacturer's manuals and diagrams, troubleshooting skills, operator's knowledge, and time are all required to solve issues in maintaining a modern manufacturing production line.

About the Author: Larry Bush has been an electrician for 47 years and in maintenance management for 22 years. Download his eBooks "Maintenance Policy and Procedures Manual" or "Emergency Diesel Electric Generators eBook"!

Related Products:

Industrial Electrical Training Video Course Library

Industrial Electrical Troubleshooting Simulation Software

PLC Electrical Troubleshooting Course

PLC Training Course and Simulator

Contrologix - RSLogix 5000 Course

Hazardous Area Instrumentation Training"