Maintenance Management and Asset Management

4.1 Great benefits of a CMMS?

4.1.1 A Diary and Personal Organizer Tool

The CMMS acts as your diary. You record future maintenance needs for your assets. Use it to plan your day, week, and year. Manage all jobs in detail—from 1-hour maintenance routines to 4-week shutdowns. Review tasks when they come up to ensure plans still fit. A year is long, and things can change.

In the CMMS, enter all resource needs like cranes, scaffolding, and lighting. Include workforce requirements to ensure you have enough skilled people. List all parts and materials needed for each job. Keep track of interactions between departments. This helps jobs run smoothly and ensures important details aren’t missed.

4.1.2 A Smart, Time-saving Buying Tool

A CMMS with Bills of Materials and supplier catalogs saves time and money. You can compare costs across suppliers for the same part, ensuring the best price. It saves time because just one or two keystrokes fill in purchase descriptions in the correct format with the right part numbers. This makes getting the right parts on time much simpler.

You’ll save dozens of phone calls to suppliers each day. These benefits lead to hours saved each week for years.

4.1.3 A Cost Monitoring Tool

A CMMS shows where your maintenance money goes. Maintenance budgets often cover plant, safety, and environmental improvements. This is useful when budgets go over. You can point out unbudgeted work that burdens maintenance due to business demands.

Another key benefit is tracking costs when jobs go wrong. You can pull labor, parts, and contractor costs for review. No one likes to revisit failures, but learning from mistakes leads to better results next time.

4.1.4 Equipment Failure Analysis Tool

With a year’s worth of data in a CMMS, spotting problems becomes easier. Ensure your CMMS can export records to a spreadsheet. Once job histories are in the spreadsheet, sort by keywords to find recurring issues. I found 44 problems at one plant. These issues kept coming up for three years. Certain machines, in particular, had frequent breakdowns.

This knowledge is powerful. Once I have the time and resources, I’ll tackle these issues from most to least costly. Without the CMMS, I wouldn’t know where to focus my efforts.

4.1.5 A Trending Tool

A CMMS allows you to trend any maintenance data you want. You can track costs, hours, equipment types, and specific assets. Many CMMSs lack strong trending tools, so ensure yours can export data to a spreadsheet for analysis. It’s amazing what you can learn by visualizing numbers in a graph.

4.1.6 A Teaching, Training, and Instruction Tool

The CMMS lets you communicate directly with operators and maintainers. You can share information about the asset they work on and how you want the job done. Add pictures, drawings, materials specs, and step-by-step instructions. The CMMS can help ensure jobs are done right the first time, making everyone’s day better.

4.1.7 A Safer Workplace

A CMMS provides significant safety benefits. It can automatically supply MSDS, advise on safe practices, warn of dangers, and print necessary permits. These features create a safer work environment, helping everyone feel secure.

One effective idea is to print the Permit to Start Work alongside the Work Order for a job. No job starts without both documents signed by operations, ensuring safety. The Permit outlines safety precautions and is generated automatically with the work order.

4.1.8 Accounting Benefits

CMMS users gain several accounting benefits. You’ll enjoy faster invoice matching. There will be fewer invoices, better cash flow projections, and more accurate budgeting. Plus, you’ll have tighter cost control.

4.1.9 Production and Operations Benefits

A CMMS isn’t just for maintenance. It helps production teams run the plant more efficiently. The system sends reminders to operators for cleaning and monitoring tasks. This helps the plant run at its best. This control empowers everyone to feel more in charge.

A CMMS is a smart tool for smart people.

Guarantee Successful CMMS Implementations.

Most CMMS implementations fail. The users, i.e., the operators and maintainers and their direct supervision, will not support outsiders’ efforts. It’s human nature! They often wonder, "What do office workers and university graduates know about life on the shop floor and in production plants?"

For a successful implementation, don’t let the IT Department handle the CMMS. What do they know about maintenance and operations? Don’t let the engineers handle it alone. Engineers without good 'people skills' or shop-floor experience might find it hard to understand the views and needs of tradespeople. They will be considered outsiders, too!

For consistent success, ensure production and maintenance oversight. Have a lead maintenance technician handle it under expert guidance from maintenance management. When supervisors and planners in maintenance and operations adopt the change, they will share it with the rest of the organization. They will ensure that everyone uses it correctly. (Aha – now I’ve told you the secret of how to deal with production and maintenance people! Work through the supervisors and lead maintenance technicians! Keep it to yourself and don’t tell anyone!)

Let them take care of it all: naming conventions, asset numbering, work order codes, chart of accounts, store cataloging, management reports, and more.

But give them guidance. Assets are numbered in specific ways for a reason. Stores use certain formats for their catalogs for good reason. Job codes are designed to be clear and understandable. Reports for managers are created with a purpose. The supervisors are bright people. Once they grasp why things are done a certain way, they can ask a few questions. Then, they can figure out the best way to set up the CMMS for the organization and themselves.

A CMMS can be good for an organization, it will save money, resources, time, and effort. But you must sell it and do it the right way so that the people that must use it and enter the data will support it!

4.2 Equipment criticality

How do you choose the right maintenance level for each piece of equipment and its sub-assemblies? Not all machines are equally vital to your business. Some are critical to production; without them, the process halts. Others are important too, but their failure will affect production if not fixed in time. Then there are items that are not important at all and can fail without impacting production for a long time.

As a maintainer and operator, you need to know which equipment fits into each category. This knowledge helps you decide your response. You also want to identify which sub-assemblies are critical for the machine's operation.

With this information, you can determine which spare parts to keep on-site and which to order as needed. The importance of the equipment decides how much preventive maintenance we need. It also affects the type of condition monitoring required and what operators should watch for. Additionally, it helps justify the use of online monitoring systems to prevent catastrophic failures.

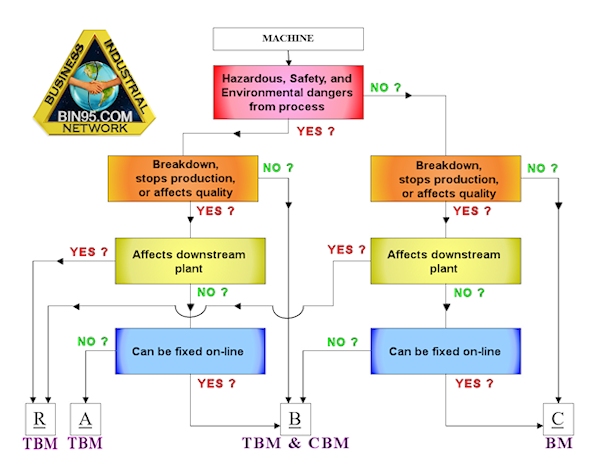

Two standard methods for assessing criticality are Reliability Centered Maintenance and Risk-Based Maintenance. Both methods consider the consequences of failure and outline responses to mitigate them. Another way to determine criticality is by considering the ripple effects of a failure and its consequences. This approach is quick and follows a simple four-step process.

Operations and maintenance teams work together to assess each piece of equipment using the flowchart below. Failures that pose safety and environmental risks must be prevented. Either the parts are kept as spares and replaced before failure, or the equipment is placed on a condition monitoring program. Failures that lead to production loss or affect quality are also addressed similarly. Those that aren't critical are treated as breakdowns.

The flowchart helps determine a rating and corrective action for each piece of equipment and its components. If a loss causes danger, stops production, or affects quality, it should be replaced before it fails. Otherwise, it needs close monitoring.

In the equipment criticality flowchart above ...

TBM = Time Based Maintenance

CBM = Condition Based Maintenance

BM = Breakdown Maintenance

Want to dive a little deeper into Equipment Criticality? See our 61-page eBook "Production Risk Management using Equipment Criticality Analysis eBook - 2nd edition". The risk management and criticality analysis eBook helps you take action. It shows you how to create effective strategies to manage and control risk. (Risk control by criticality analysis, FMEA?, QRA? and RACM?)

4.3 Work planning and scheduling

The efficient use of people, materials, and resources needs good coordination and preparation. When a job starts, everything needed must be ready to use. The maintenance planner handles this preparation before the job begins. Their goal is to ensure all necessary items are on hand for a smooth job completion. Effective planning has a direct impact on how efficiently the team works and how long tasks take.

Why plan? Planning maintenance work maximizes the benefits of time, money, and effort. It greatly improves maintenance productivity. Verified improvements can reach 50% compared to jobs without planning.

Planning and scheduling are distinct tasks. The planner works separately from the maintenance department. This helps minimize distractions from sudden issues.

The planner is not the scheduler. The maintenance supervisor handles scheduling. The planner compiles a comprehensive work package. This includes materials, tool lists, procedures, drawings, and equipment history. It also covers job times, staffing needs, and external resources, such as cranes. After preparing this, the planner moves on to the next work order.

Breakdown jobs can't be planned. They go directly to the maintenance supervisor. The planner does not get involved in breakdowns or ongoing jobs. Their role is to stay ahead of daily work and ensure fresh tasks are ready for the crew.

The crew fixes any problems that come up during a job. They handle it on their own, without asking the planner for help. The planner learns of the issue through the work order report and notes it for future planning.

Productivity goes up when all planning, parts, and information are ready. This lets tradespeople start work right away.

A good planner has critical qualities. They are organized and possess a deep familiarity with the plant and equipment. They read and write clearly. They understand drawings and equipment records. Also, they are skilled with computers and software. They should be outgoing, comfortable communicating with various people, and willing to ask questions.

Scheduling involves timing the job. It involves choosing who will do the work, what resources are needed, and confirming dates and times for accessing the plant and equipment.

Planning can occur months in advance, but scheduling happens closer to the job date.

The key concept behind planning.

The Chinese philosopher Confucius said, “In all things, success depends on previous preparation, and without such preparation, there is sure to be failure.”

Confucius was right. To succeed, you must prepare before taking action. A maintenance planner gets ready for the maintenance work. A scheduler organizes the people who will do it. The planner organizes everything needed for a job, but they do not schedule it. That job goes to the team in charge of personnel and equipment access.

Once the planner hands over a complete work pack, their job is done. They achieve success at that moment. The planner gathered all the parts, tools, resources, and info needed to finish the job. They can then move on and start preparing for the next maintenance task.

- Plan first.

- Plan in detail.

- Plan then purchase.

- Hand over the completed work pack to Maintenance.

- Go back and plan the next job.

- Maintenance supervision schedules the planned work with Production supervision last.

A planner’s job perspective and requirements are to.

The Planner’s time scale is 5 days away and longer. Planners cannot help with breakdowns and rush jobs. It is already too late to plan! In a breakdown, you can only react to what you find during the repair. The maintenance crew's team leader looks after breakdowns and those ‘must-be-done-today’ jobs.

Don’t bother your planner if you experience a breakdown or if you must complete the job within the next 5 days. The planner's role is to anticipate today’s problems and prepare for next week’s successes. If you stop them from doing that, you will stop having future successes. The planner’s success today is everyone’s success tomorrow!

Three questions:

What exactly is maintenance planning?

To satisfy Confucius's advice, maintenance planning is about preparing to achieve success. Do whatever is necessary to guarantee successful outcomes.

What exactly should a maintenance planner do?

To make the most of time, money, and effort, the planner needs to handle all the thinking, reading, procedures, and investigations. This way, the maintainers can focus more on using tools for the plant and equipment. Good planning leads to more tool time. It means machines get fixed fast and correctly. Plus, it requires fewer people and less supervision.

Where does the maintenance planner need to be located to do his job properly?

The planner’s time focus is 5 days or longer. They cannot sit where the maintenance time focus is today and tomorrow. The planner must sit in an area where they are not disturbed by day-to-day issues. The planner should maintain regular contact with Production. This way, they can understand their priorities and schedule. The planner sits in the Production office.

The planner must report to people whose time focus is longer than 5 days. They can't report to workshop supervision focused on today and tomorrow. If they do, the planner becomes a 'gofer' for urgent tasks. This leaves no time to stay ahead of the workload. The planner reports to the Maintenance Manager and not to ‘shop floor’ supervision.

Let me say it one more time, because it is so important to your success –

“The Planner’s job is to get ahead of today’s problems and prepare for next week’s successes. If you stop him or her from doing that you will stop having future successes. The planner’s success today is everyone’s success tomorrow!”

The world-class players are great planners. They have a minimum 5-year plan. This plan includes 1-year plans, monthly plans for major events, and daily plans. The planner plans all activities in detail. They review their performance weekly with Key Performance Indicators. This helps them see how to improve and achieve better results. They plan carefully to maximize their tradespeople's 'wrench time.' This helps improve workforce efficiency.

You might also want to check out the PowerPoint for "The Maintenance Planning and Scheduling Training" course. It's different from many others. These 229 slides across 3 Management PowerPoints tell a story. We hope you find it entertaining while you learn. The author wanted to make training fun for you to do and for him to write. He turned the PowerPoint into a story. It’s about Ted, an imaginary character, who learns to be a 'Top-Gun' Maintenance Planner and Scheduler.

4.4 Preventive Maintenance (PM)

Preventive maintenance means checking equipment regularly. This involves moving around and using your senses. You look, feel, listen, smell, and even taste.

- Lubrication checks

- Drive train monitoring

- Equipment mounting inspections

The three key parts of classical Preventive Maintenance are:

You can quickly create Preventive Maintenance work orders with a Computerized Maintenance Management System. Setting up work orders for these three inspection areas should reduce breakdowns in about two months.

For lubrication PMs, include greasing and oil level checks. List the machines to be greased and the gearbox oil levels to check. Use checkboxes to mark completed tasks and to note any leaking shaft seals. Don't let seal leaks drain a gearbox of oil.

Highlight grease nipples by painting around them to ensure none are missed. Train the person doing the lubrication on the basics. Stress the importance of doing the job well and watching for lubrication and roller bearing issues.

Drive train monitoring checks v-belts, pulleys, drive chains, sprockets, and couplings. This helps spot wear and stress. V-belts should have no cracks and a full profile. Check pulley alignment with a straightedge. Pulleys must show no signs of slippage. Check sprockets and chain links for wear and alignment. Look for signs of distortion in coupling members. If the same machine often shows defects, investigate and implement improvements.

Equipment mounting inspections include checking for loose bolts and broken foundations. Check for flexing base plates while the machine runs. Make sure pipe supports reduce stress at connection points. Also, feel for any strange vibrations in the machine.

The frequency of PMs depends on the industry, site, and equipment. Lubrication PMs happen more often than drive train PMs, which are more common than looseness checks. You can adjust these periods based on experience.

Top asset managers keep maintenance under control. Their systems focus on preventing unplanned stoppages. They plan and prepare for every task. They know breakdowns can be overwhelming. But preventive maintenance can be planned. Planned work is the most cost-effective maintenance strategy. World-class asset management organizations have over 80% of their workload in preventive maintenance. This is the way to great asset management—focus on preventive maintenance.

To achieve world-class asset management results, control your maintenance. Target low equipment failure rates with all your strategies and practices.

4.5 Work order instructions and history reporting

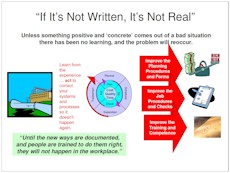

Use written work instructions to make it clear.

Equipment maintainers get written directions as job procedures or job instructions. They reduce the chance of making an error and reduce the time spent looking for information. Job instructions help you plan, document, and organize tasks. This way, you can achieve the best results. Once someone writes them, they reuse them forever.

The single job instruction document list:

- The individual steps to ensure the work's safety.

- Any special requirements that the tradesman should know, like part tolerances.

- All interactions with other trades personnel who will be needed for the job.

- All needed external resources, like cranes or specialists for ultrasonic thickness testing.

- All the tools needed to complete the job.

- A complete parts list with drawings.

- An indication of the likely time to complete the work.

- Contact details of whom to call in case something unexpected occurs.

This document saves time and effort as it contains all the information a tradesman needs to know to do the work. It is a ‘live’ document that gets updated as we learn more about the job and its equipment.

Job instructions are compiled for routine work that occurs on a regular basis. They can also use them for hazardous work that they must do carefully. They can be written to cover a half-hour job of a two-week outage.

Job instructions are great because they let you think deeply about a task. They help you plan well for future situations. It is clearly a great way to save time and to pass on knowledge. This means the best person to write the procedure should be someone who knows the job well. This is often a tradesman, team leader, or supervisor who has done the work many times.

Remove the person writing the procedure from their daily tasks. Focus them on creating the instructions. Although writing takes time, this document will consistently save time.

Procedures speed up training for new staff. They cut down on breakdowns since equipment is rebuilt with complete knowledge. This saves time on the job, as all information is available to the tradesman. Also, it builds confidence in the work being done.

Work order job history recording

The work order report lets the maintainer inform the engineer about equipment issues in the plant. It also provides a precise record of what the team found during repairs. Thus, completing these reports in detail is crucial. Managers and engineers must review them.

Reporting on a completed work order is essential. Tradesmen often see it as a tedious task with little value. This view is incorrect.

Each repair holds valuable information to enhance the future performance of the equipment.

This information is important only if those who can fund improvements are aware of the issues. The work order report enables tradesmen to inform maintenance management about equipment issues and potential solutions.

A smart maintenance engineer will read all work order reports for their area. This practice offers insight into the plant from different perspectives. If maintenance middle managers skip these reports, plant and equipment upgrades will lag.

A solid work order report describes what the maintenance worker observed. For example, “There were score marks around the shaft under the bearing inner race.” This suggests the inner race may have spun, causing excessive clearance. It could also mean the bearing is too hot. This might need changes to drawings or lubrication checks. Another example is, “The rubber in the shaft lip seal was hard and cracked.” This could show that the temperature was too high for the seal or that someone used the wrong seal.

The tradesman’s comments are critical in the effort to continuously improve plant performance.

A good work order report also tells the reader what the tradesman did to fix the repair. The phrase “Polished bearing seat and fitted new bearing” shows that the issue isn’t resolved. It suggests the problem may happen again. But - “I checked the shaft tolerance and found that it was undersized by 0.05 mm. Machined the shaft and shrunk-fit a sleeve. "Machined the sleeve to meet tolerance and installed a new bearing." This suggests that an undersized shaft is likely not the problem.

Or, you can buy a PDF version below. You can then access the guide offline. You can also print it for your maintenance staff, operators, or students.

On to chapter 5, Fault Finding and Troubleshooting Check Lists >>

<< Back to chapter 3, Maintenance Philosophies and Methods